View from the Other Side

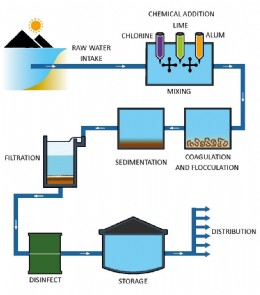

Figure 13.2.a. Potable water treatment plant. Image by permission of Rotork

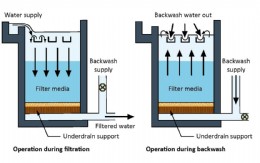

Figure 13.2.d Automated valves for backwash control. Image courtesy of AUMA.

Figure 13.2.c Filter and backwash in a potable water plant.

Figure 13.2.c Filter and backwash in a potable water plant.

Potable Water Treatment

Historically, one of the first infrastructure projects of any city, town or village has been a potable water supply. That means many new plants are being built in areas of expanding population. Also, in developed areas of the world, many existing water treatment plants are old and need modernizing. Valve actuators play an important role in maintaining the quality of our water supply by contributing to the efficient operation of potable water filtration plants.

The process in a water plant takes raw water from rivers, lakes or other sources. A chemical coagulant is added to the water such as aluminium sulphate. The coagulant, when mixed into the water, causes the small solid particles to stick together in a process called flocculation. The water passes into large clarifiers that allow the solids in the water to settle to the base of the tank where they are collected for disposal

The water then passes through an ozone or other type of disinfection process on its way to the filtration process.

At the filter bed, the flow of clarified water is introduced into the top of the filter along troughs. The water runs down through the filter media with large particles trapped first and finer particles adhering to the lower filter media. At the bottom of the filter, the bottom drain pipework collects the filtered water; it is passed on to the secondary disinfection stage, after which the water is stored ready for distribution.

The process is continuous, with the exception of the filtration. These filters have to be cleaned regularly by reversing the flow to “backwash” the trapped particles out of the filter media to waste. This means the filter has to be taken out of the process (taken offline) while this is done. Water treatment plants have several filter beds so that while one is backwashed, the others can continue the process flow.

Automated valves are used in many locations around the plant to control the flow of water through the various processes using sluice gates, butterfly valves and gate valves with electric or fluid-powered actuators. Usually the fluid-powered actuators are pneumatically powered, although decades ago many hydraulically powered actuators used the processed water under pressure.

A key automated valve is the rate-of-flow control valve. This valve is usually a butterfly valve and is modulated to ensure the rate of flow through the filter keeps the water level above the filter media but below the filter tank top. Sensors near the top of the filter sense high and low levels. The flow of water through the filter changes as solids build up and reduce the flow throughput. Because this would increase the filter water level, the rate-of-flow controller compensates by opening the rate-of-flow butterfly valve to increase effluent flow.

The most complex process is the backwash sequence needed to periodically remove solids from the filter. The backwash procedure drops the water level to just above the top of the media. The filter media is then agitated to loosen solids. This is done by pumping air up through the filter to loosen the filter media as well as the filtered solids, a process known as air wash or air scour. The top of the filter media may also be agitated by a “surface wash” system. Clean backwash water is then pumped up through the bottom of the filter by the backwash pumps. The solids are washed up and into the troughs at the top of the filter and out as waste. The inlet and outlet valves to the filter have to be sequenced carefully to ensure the correct flow; a sudden inrush of water could damage the filter by displacing the strata of the media. This sequence of events is usually done automatically by the process controller. Once the outflowing water reaches an acceptable level of clarity, measured by the turbidity sensor, the backwash is stopped and the valves are actuated back to their normal filtered position.

Published: 13th May 2016

Rachel Wormald, Managing Director at YPS Valves Ltd and Elizabeth Waterman, ...

Are you looking for industry-leading, brand independent valve and actuator ...

As can be seen from the photograph, clearly the resident birds at Bartlett ...

Howco Group has unveiled its latest £1million investment, with the ...

In 2024, Allvalves is poised for an exciting year of growth and expansion, ...

GMM Pfaudler Engineered Plastics & Gaskets are delighted to bring the ...

In the ever-evolving valve industry, GMM Pfaudler stands out for its ...

SAMSON Controls Ltd – part of the SAMSON group - a renowned leader in ...