Slam Shut Cabinets - Drallim

The cabinets, of which there are sixteen variations, in conjunction with Slamshut valves, monitor the gas pressure and rapidly cut the flow of gas when the pressure in the system exceeds the set point and avoids overpressure conditions.

National Grid had a large number of slam-shut control systems operating on twin-stream and triple-stream Pressure Regulating Installations (PRIs). Many installations were over 25 years old and required replacement to ensure that safety systems were kept in good order.

A number of different designs were in operation, all of which performed the same function but varied slightly.

In order to achieve the benefits of standardisation National Grid opted for one particular system design as a replacement.

The system is an up-graded version of the original Select-a-Stream which was designed in the East Midlands in 1989.

‘Select-a Stream II’ is a system of slam-shut stream selection designed and developed by National Grid and manufactured by Drallim Industries. It has been developed from, but is not identical to, the original ‘Select-a-Stream’ systems that were used within East Midlands Network of National Grid.

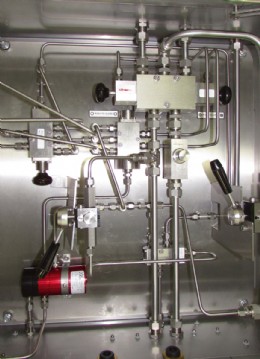

The system consists of a control cabinet for each regulator stream. For each installation one cabinet is designated as the ‘Master’.

The control cabinets for the other streams differ slightly from the ‘master’ in their internal pipework and are designated as ‘Slaves.’

The principle of operation for a two-stream installation is as follows:

When the station outlet pressure rises, the lead stream slam-shut will close when its set point is reached. If the outlet pressure continues to rise, the slam-shut on the standby stream will then close.

If the outlet pressure subsequently falls, the standby stream slamshut will reopen to maintain gas supplies. If the outlet pressure again rises above the set point (e.g. If the standby stream is faulty), the standby stream slam-shut will again close and will not reopen. If the outlet pressure falls again, the lead stream will now reopen to maintain gas supply. Should the outlet pressure rise above the set point yet again, the lead stream slam-shut will again close and will not reopen.

The principle for three stream operation is exactly the same. The streams will close in ascending order of set point. When all streams are closed, should the outlet pressure fall, the last slam-shut to close will reopen first. Each stream will only re-open once.

It later became apparent that the customer specified 3-way ball valves, although of superior quality, had begun to fail in the field. This occurred at low temperature due to cross port leakage; a well known Achilles heel of even the best multi-port ball valves. This caused the Slamshut valves to trip and close at the wrong time, a very unwelcome outcome on a mains gas pipeline. Drallim Industries offered an easy retrofit solution utilising their own Rotary Selector Valve (RSV) which has much more reliable cross port sealing in demanding applications. After passing low temperature tests at -40°C, a special variant was produced with matching interface dimensions to that of the failed ball valves.

This replacement program was approved by National Grid Gas. Drallim was awarded the contract to rectify the issue and modify the built units with a further value of 1.2 million GBP.

Since the completion of the projects Drallim Industries have been given a Licence Agreement by National Grid Gas (now known as Cadent) to promote, manufacture and supply Slam Shut Cabinets of this design to other Gas Networks which has proven successful.

Tel: 01424 205 140

Email: sales@drallim.com

Web: www.drallim.com

Published: 23rd August 2018

Rachel Wormald, Managing Director at YPS Valves Ltd and Elizabeth Waterman, ...

Are you looking for industry-leading, brand independent valve and actuator ...

As can be seen from the photograph, clearly the resident birds at Bartlett ...

Howco Group has unveiled its latest £1million investment, with the ...

In 2024, Allvalves is poised for an exciting year of growth and expansion, ...

GMM Pfaudler Engineered Plastics & Gaskets are delighted to bring the ...

In the ever-evolving valve industry, GMM Pfaudler stands out for its ...

SAMSON Controls Ltd – part of the SAMSON group - a renowned leader in ...