Leengate Valves Committed to Offshore & Marine Markets with New Products

Leengate Valves show commitment to offshore and marine markets with new products and highly reliable supply chain

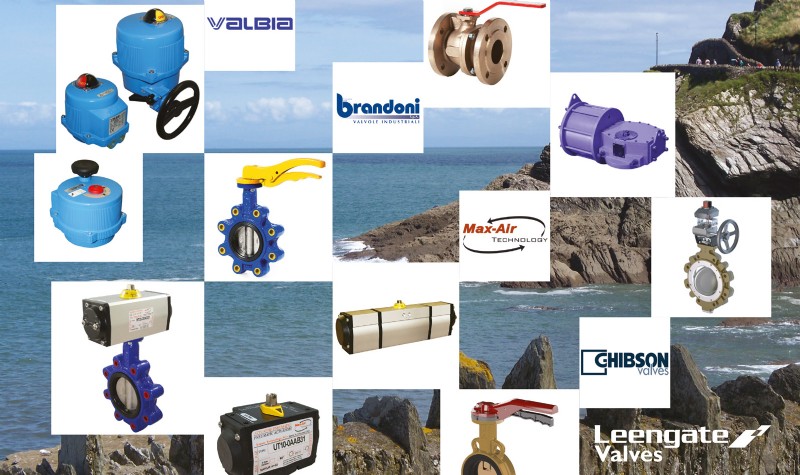

The aluminium bronze additions are manufactured by Ghibson; a solid, reliable brand within the offshore/marine valve industry. These new additions to the Leengate range are wafer pattern to suit PN10, PN16 or ANSI 150 flanging and offer a fully aluminium bronze construction and NBR liner; excellent for the processing of seawater in salt air environments.

As well as offering suitable aluminium butterfly valves, Leengate also have a good supply of bronze and aluminium bronze ball valves, flanged to PN16 and ANSI 150, and actuation solutions that can satisfy a variety of demanding offshore environments with great efficiency.

Managing Director, Steve Pickering said, “Our status as exclusive UK distributors for Max-air, Ghibson, Brandoni and Valbia has been instrumental in the increase of service in the offshore and marine areas. We can offer customers a reliable chain of supply, decades of experience and a great quality product.”

In addition to their standard valves, Leengate Valves’ well equipped actuation centre can offer automated solutions for many different processes. With a range of supply from Max-Air and Valbia, including an exhaustive selection of materials and coatings, Leengate Valves’ team are always keen to supply an efficient solution for its customers. Material and coating options include, among others, glass reinforced polypropylene pneumatic actuators, technopolymer electric actuators, electroless nickel infused aluminium and polyamide epoxy coatings - which are known to be a particularly good at resisting corrosion from salt air.

“A strong relationship with manufacturing partners in Europe has proven vital to our intensified efforts in the marine and offshore market. Customers are benefiting from decades of networking and an environment that offers good availability of products, quick delivery times and an all-around reliable supply flow,” said Arran Macalister, Engineering and Actuation Manager at Leengate Valves.

You can speak to a member of Leengate Valves’ team by calling (0044) 1773 521 555 or emailing info@leengatevalves.co.uk.

Tel: 01773 521 555

Email: info@leengatevalves.co.uk

Web: www.leengatevalves.co.uk

Published: 23rd August 2018

Rachel Wormald, Managing Director at YPS Valves Ltd and Elizabeth Waterman, ...

Are you looking for industry-leading, brand independent valve and actuator ...

As can be seen from the photograph, clearly the resident birds at Bartlett ...

Howco Group has unveiled its latest £1million investment, with the ...

In 2024, Allvalves is poised for an exciting year of growth and expansion, ...

GMM Pfaudler Engineered Plastics & Gaskets are delighted to bring the ...

In the ever-evolving valve industry, GMM Pfaudler stands out for its ...

SAMSON Controls Ltd – part of the SAMSON group - a renowned leader in ...