AUMA Electric Actuators Awarded Gas Industry Standard VA2

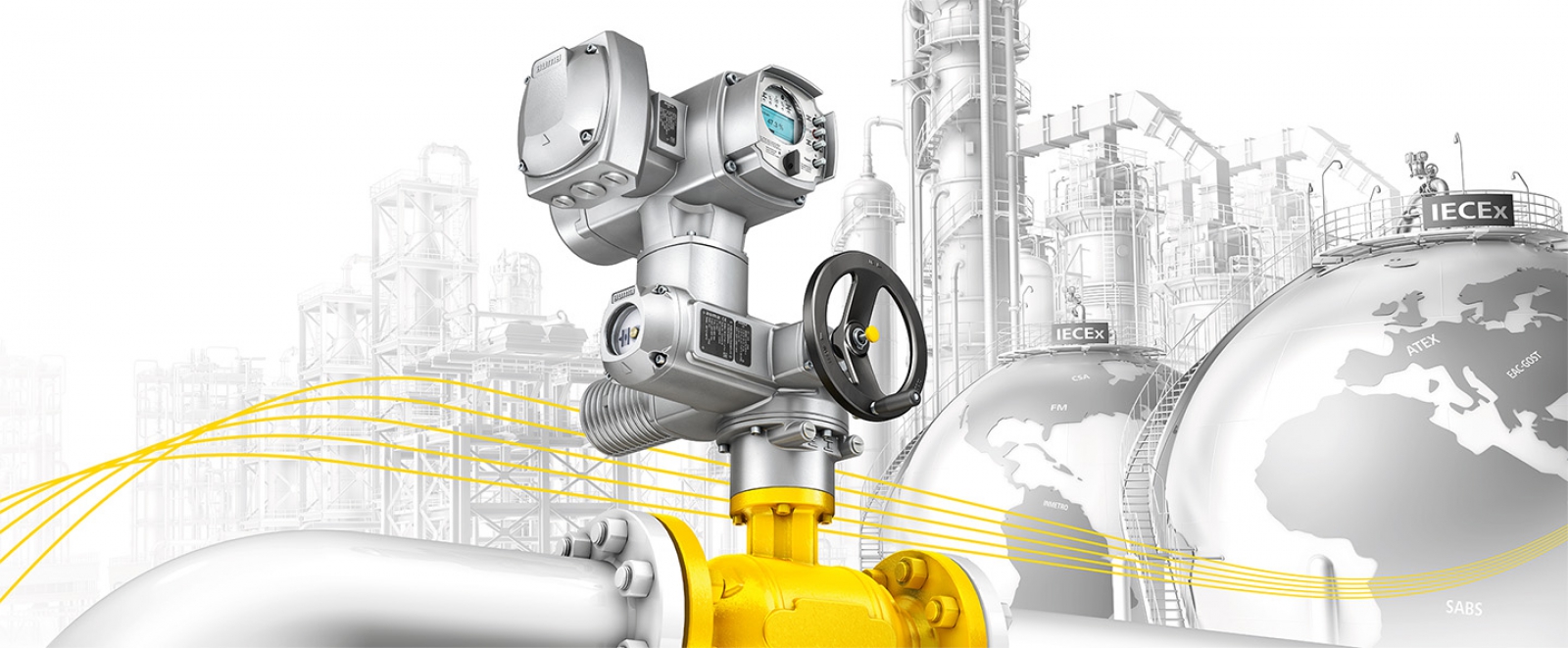

National Gas has approved AUMA Actuators Limited's explosion proof range of high-performance electric actuators with the Gas Industry Standard VA2 certification.

Gas Industry Standard (GIS)/VA2 specifies the requirements for electric powered actuators, for use with two position (open/closed) quarter turn valves manufactured to the requirements of GIS/V6. AUMA's range of SAEX and SAREX actuators, with the combination of ACEX Controls, are GIS/VA2 compliant.

Paul Hopkins is AUMA’s managing director. He says: “Explosion-proof devices must be used in plants where potentially combustible atmospheres may occur. AUMA’s comprehensive range of VA2 approved devices is designed so that they will not act as an ignition source. Each is designed and manufactured to exacting specifications to prevent the occurrence of ignition sparks or hot surfaces.

“AUMA’s actuators meet and exceed the critical performance requirements of the gas industry, receiving international certification in explosion protection, high Safety Integrity Level (SIL) capability, and perfect reliability in particularly harsh and arduous climatic conditions.”

Actuators manufactured to VA2 are suitable for use in areas in which an explosive gas atmosphere is likely to occur in normal operation; with atmospheres containing propane, or gases and vapours of equivalent hazard, compliant with the Dangerous Substances and Explosive Atmospheres Regulations (DSEAR) and Atmospheres Explosible (ATEX) regulations.

AUMA’s new TIGRON actuators are also designed to meet the exacting requirements of the global gas industry, combining the highest level of explosion protection, robust design, outstanding ease of operation, and the latest trends in digitalisation. The versatile all-rounder provides safe and reliable valve automation across all application sectors, including oil and gas production, pipelines, tank farms and refineries.

TIGRON actuators are ATEX and IECEx certified for the highest gas group IIC, which includes highly flammable hydrogen. Actuators are designed to withstand the harshest environmental conditions, covering a particularly wide temperature range from –65 °C to +75 °C.

AUMA’s ATEX approved PROFOX for butterfly, ball/plug and globe valves is a compact actuator that features a range of intelligent functions for tailored automation solutions. Each ATEX approved PROFOX is equipped with a centrally located LED: The FOX-EYE. It provides clearly visible information about the actuator and valve status. The FOX-EYE display scheme can be configured by the user as required.

|

Tel No: |

01275 871141 |

|

Email: |

|

|

Website: |

Published: 18th September 2023

Valveuser Magazine Issue 91 is the first of our Special Print Editions for ...

BVAA’s Director Rob Bartlett comments, “In 2024, the BVAA will be ...

Spring Conference & Golf Day, 22-23 May 2024 at Mottram Hall, ...

As 2024 is BVAA’s 85th Anniversary year, I recently had the perfect ...

The international event of reference for industrial valves and flow control ...

As long-term readers of Valveuser will know; Heap & Partners Ltd was ...

WIRRAL manufacturer Heap & Partners has recently celebrated one hundred ...

IMI has announced a record year for orders throughout the hydrogen value chain ...