AUMA Goes Green with Commitment to Net Zero

Investment in a range of renewable energy technologies by an electrical actuator supplier based near Bristol is reaping returns through reduced energy costs and meeting sustainability goals, saving over 236 tons of CO2 and generating more than 420 MWh of energy.

AUMA Actuators Limited - part of the AUMA Group, one of the world’s largest manufacturers of modular electric actuators - generates electricity from 178 photovoltaic (PV) panels on the roof of its Clevedon office and warehouse, whilst heating and cooling is generated using electric air-source heat pumps. The building’s lighting uses energy efficient LEDs. The company also operates a fleet of electric and hybrid vehicles.

Paul Hopkins, Managing Director, AUMA Actuators Limited, says: “We believe that every business has a responsibility to reduce its carbon footprint. We are using the guidance provided by the Carbon Trust to accelerate our journey to Net Zero.

“At AUMA, we’ve been on the front foot since 2010, investing in the installation of 178 PV panels that make best use of the roof of our building. That investment alone has removed the equivalent of 50 cars off the roads over the last 13 years. That may sound underwhelming, but it’s these small savings that together accrue into major benefits.

“Alongside PVs and our electric air-source heat pump, we encourage our team to cycle to work, taking advantage of the Government’s scheme that provides tax incentives to enable employees to buy bikes at a reduced cost. We have also taken steps to reduce our water consumption. And we have made significant progress in transitioning our company fleet to environmentally friendly vehicles, with over 50% now being hybrid or fully electric.

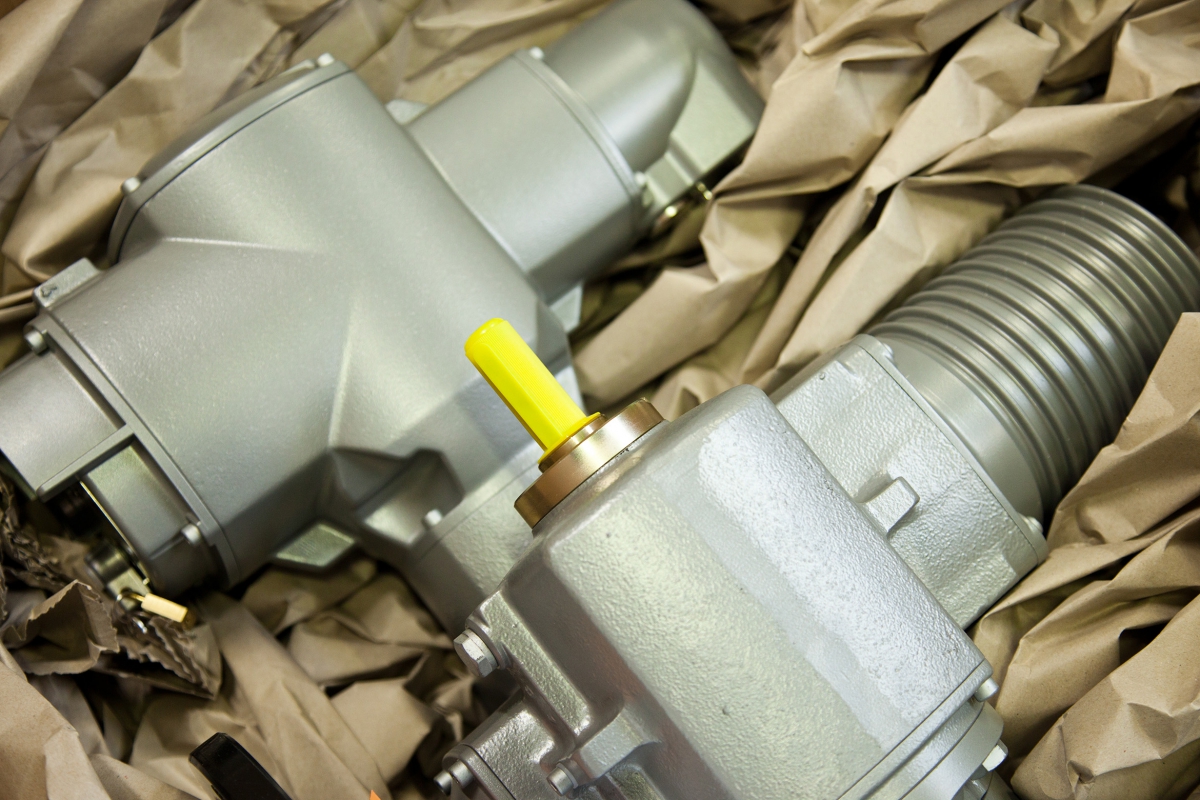

“But our commitment doesn’t end there. We continue to identify opportunities to reduce waste, removing the requirement for plastic packaging by introducing innovations such as reusable wooden crates for the delivery of actuators to site.”

The UK Government's Net Zero strategy sets out policies and proposals for decarbonising all sectors of the UK economy to meet net zero target by 2050.

AUMA’s broader sustainability agenda has developed from energy efficiency in its operations, to carbon, renewable energy, water and waste reduction, through to supply chain goals.

AUMA Actuators Limited is a major supplier of electric actuators to the water, gas and manufacturing industries. Customers include Anglian Water, Thames Water, and National Gas.

For further information visit:

T: 01275 871141

Published: 27th October 2023

Rachel Wormald, Managing Director at YPS Valves Ltd and Elizabeth Waterman, ...

Are you looking for industry-leading, brand independent valve and actuator ...

As can be seen from the photograph, clearly the resident birds at Bartlett ...

Howco Group has unveiled its latest £1million investment, with the ...

In 2024, Allvalves is poised for an exciting year of growth and expansion, ...

GMM Pfaudler Engineered Plastics & Gaskets are delighted to bring the ...

In the ever-evolving valve industry, GMM Pfaudler stands out for its ...

SAMSON Controls Ltd – part of the SAMSON group - a renowned leader in ...