Keep the noise down

High noise can be a problem in even low and medium pressure steam applications.

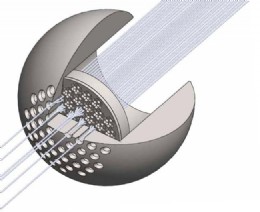

Figure 1. The principle of anticavitation and noise reduction (Neles Q-trim).

Figure 2. Enhanced noise attenuation with new Q2-trim.

Short theory behind source treatment Velocity control

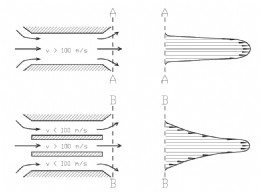

Figure 3. Effect of increasing the number of holes on noise level

Figure 4. Jet velocity profile modification.

Essential utilities

Steam is a very common utility and widely used in several industries like power production plants where high pressure drops and vibration is a common concern. Steam is needed for various purposes in chemical and hydrocarbon processing: It can be used as a source of power, taking part in a reaction, like in steam reforming to produce hydrogen; or it can be used as stripping steam in columns and reactors, purging piping and equipment to keep them clean from fouling such as in delayed coking coke drum operations and steam cracking furnaces in ethylene production. Wherever steam is used, there is a likely need to control noise and large pressure drops. Industrial gases, namely hydrogen, nitrogen and oxygen, take part in many hydrocarbon processes as well. Special attention has to be taken in the sizing andselection of valves to ensure that the valves, especially in oxygen and hydrogen service, are clean, safe and reliable alongside keeping the noise levels down. Often special materials are also required, like Monel.

Compressors and surge

Compressor surge protection is one example of a severe application, where controlling noise and the resulting vibration plays a vital role in protecting the compressor from serious damage. Compressors are common equipment, from petrochemical ethylene gas compressors to large air separation plant compressors. Capacity instability is accompanied by a characteristic noise known as pumping or surge. The resulting violent gas pressure oscillation can cause severe and costly damage tothe compressor in a few seconds. The anti surge valve must be able to pass approximately 100% capacity of a compressor, react quickly, often handle a high pressure drop, and reduce noise and vibration while keeping a tight shutoff to avoid energy losses in the system.

Answering noise demands

How does a valve manufacturer answer these extreme demands when noise needs to be controlled under various flow conditions and ever tightening noise level requirements? One will start by looking at the history and milestones of flow control noise abatement technology developments that are leading the way to modern technologies.

Rotary control valves have been used for decades in numerousprocessing industries. In the late 1970s, rotary control ball valves were already in wide use. The same design of the first low noise anticavitation, patented Neles® Q-Ball introduced in 1979 still works on the same field proven principle of a multi stage trim of variable resistance depending on the valve opening. The difference between the noise level of a Q-trim ball and conventional ball can be up to 20 dBA. The Q-trim ball also has wider rangeability, and it is not sensitive to fluid impurities. The Q-trim ball became a common solution for many applications in steam, gas or liquid service. The next step towards higher pressure drops was taken in the mid 1980s when diffusers were introduced and sized so that their performance was optimised in conjunction with the control valve. The segmented ball control valve introduced in the 1980s added more possibilities in the way of extremely wide rangeability to flow control. Using Q-trim in segmented ball valves gives a control valve with low recovery.

The late 1980s saw an extension in the applicability limits of the control butterfly valve when the silencer disc (Neles S-DiscTM) was launched. The solution was again very simple. The non-symmetrical pressure distribution pattern on both sides of the disc has been made symmetrical with a partial flow obstacle (S-Disc) inside the valve body. This design helps to eliminate the dynamic torque, and because of the more turbulent flow pattern, it lowers the high recovery behaviour.

Decades of experience and development form an essential basis to take further development steps in control valve noise abatement. Controlling noise and understanding the fluid behavior in valves is based heavily on experimentation and supported by computational fluid dynamics.

The new Q2-trim is the second generation of Q-trim technology and is designed to reduce high aerodynamic noise to a tolerable level. The design itself follows the same principle as Q-trim and also utilises the same techniques of pressure staging, flow division, acoustic control and velocity control.

The idea behind the new development was to create high noise attenuation trim, which takes into account the 30 years’ history of the Q-trim and brings the noise attenuation to a new level of performance. The theory behind the design is based on the same physical phenomena that can be found with the Q-trim.

The science behind the development

What creates noise in the first place? The answer to this question is not straightforward. Although there are still unknown factors behind noise, theories have been built for them. The noise created by throttling gas or steam flow is called aerodynamic noise. There are various sources where the noise originates, for example, from the downstream turbulence of the valve, which can cause pressure fluctuations and pressure waves, high flow velocity and vibrations from shock waves. Once high noise has been generated inside a pipeline, it can propagate in several ways: inside the pipeline, along the pipe wall, along the pipe supports and into the surroundings.

Noise abatement can be done in several ways. The basic division of these is between ‘source’ treatment, like valve and trim modification where excessive noise is prevented, and ‘path’ treatment with dampening the noise generated by using silencers, insulation and heavier pipe schedule.

Source treatment is the preferred choice, whenever feasible, because it also ensures reliable process operation by preventing the high mechanical vibration levels always associated with noise. Source treatment of noise can be performed by at least four different methods: velocity control, acoustic control, location control and by using diffusers. The velocity inside a control valve trim can be controlled most effectively by using a multistage pressure drop and by increasing the valve trim outlet area such that the flow velocity and pressure at the valve outlet are at the minimum and the gas volume is at the maximum. The acoustic noise can be controlled in two ways: flow division into multiple streams and the modification of the acoustic field. Location control involves designing a valve trim in such a way that the location and the shape of the jet streams in, and especially leaving the trim, are such that the minimum amount of noise is produced. Dividing the pressure drop between a control valve and a downstream diffuser provides an effective way of further reducing the noise in cases where there is a constant, high pressure drop across the control valve and the flow is relatively constant. An attenuator plate can be used for noise attenuation in cases where the pressure drop is close to constant across the valve.

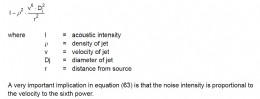

Controlling the maximum fluid velocity inside a control valve trim is a very effective way of controlling noise at subsonic flow velocities in the trim, as the acoustic intensity of a jet has been shown to be proportional to the sixth power of the flow velocity in a system with solid boundaries like a valve trim or a pipe. The relation between sound pressure level (SPL) and acoustic intensity is given.

Acoustic control

Acoustic control affects the noise level by means of acoustics. Two methods used in control valves are described here: flow division into multiple streams and the modification of the acoustic field. In theory, flow division into multiple streams is effective because the intensity of the noise generated by a single orificedecreases rapidly when the hole diameter is decreased. Thus, a number of small holes attenuates noise more effectively than one big hole. A rule of thumb is that each doubling of the number of holes reduces noise by 3 dB, as illustrated in Figure 3.

Location control

Location control involves designing a valve trim in such a way that the location and the shape of the jet streams in the valve trim, and especially leaving the valve trim, are such that the minimum noise is produced. The formation of turbulence in the mixing region between where the jet exits from an orifice and the gas flow at the outlet region as well as the attachment and interaction of shock waves (generated during throttling if the flow reaches sonic velocity in the valve) are major sources of noise that can be controlled to a certain extent by intelligent valve trim design.

One way to do this is to smooth the velocity profile of the jet by introducing a lower velocity gas stream alongside the jet, as shown in Figure 4. As mentioned earlier, the further development of enhanced noise reduction trim is based on applying the known technologies in experimental research. This method has proved to be successful in providing enhanced noise attenuation for gas and steam applications. It provides very low pressure difference over the last stage, effective flow division to reduce noise level in low and high pressure differentials, avoiding resonances and extra turbulence as well as taking into account the insertion loss related to separate static resistors.

Metso

Tel: 0870 606 1478

www.metso.com

| Telephone: | 01256 376200 |

| Email: | uk.sales@valmet.com |

| Website: | www.valmet.com |

| More information on the Valmet UK Ltd BVAA Member Directory Page |

Search related valve / actuator articles: Valmet UK LtdIssue 29Master Class