Search our database of 3579 published articles from the British Valve & Actuator Industry

Latest Industry Articles

Magazine Issues

Online Articles

Article Categories

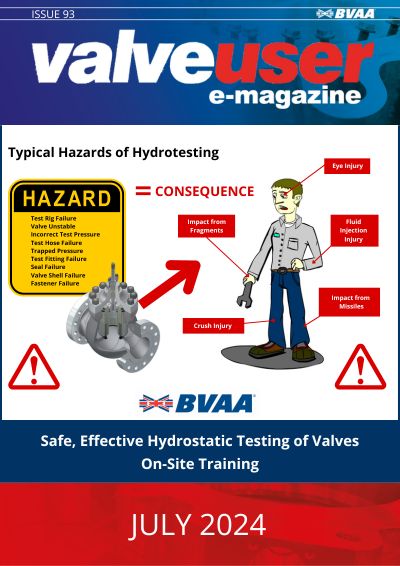

THE Definitive British Valve & Actuator Industry News Magazine

Valveuser Magazine has been published since 2007 and remains the premier specialist news journal for the Valve and Actuator Industry. Primarily sent as an e-magazine, the BVAA has re-introduced special print editions for distribution at strategic trade shows and industry events.