Goodwin International Extends its Range of Non-Slam Axial Check Valves

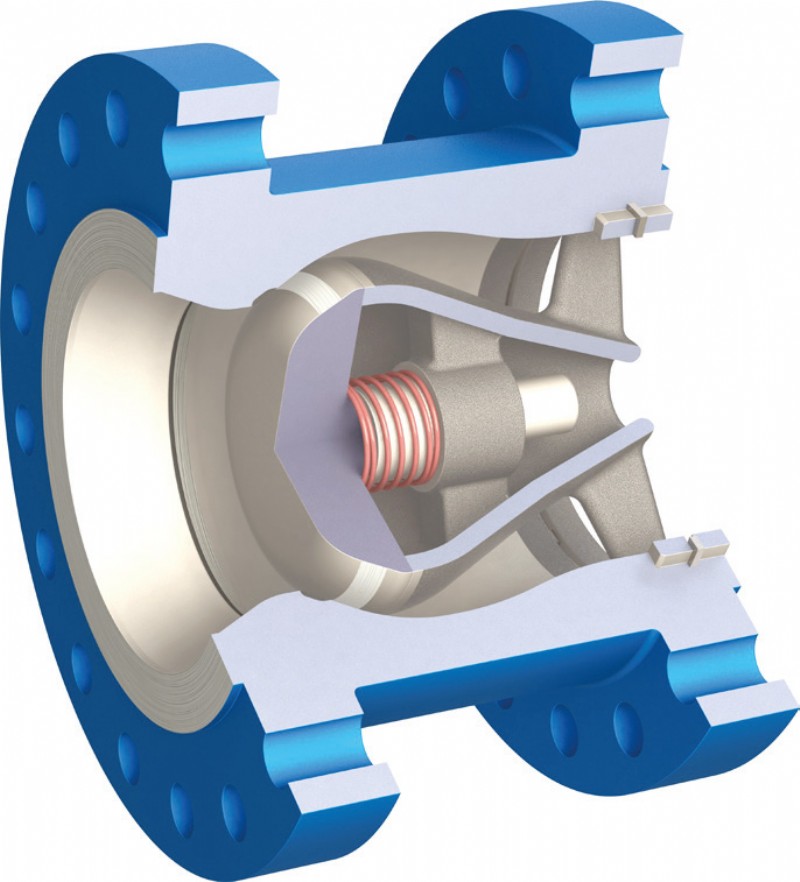

Goodwin Type Z – Solid disc (Model shown: ZBF)

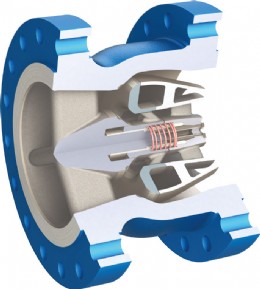

NEW: Goodwin Type NZ – Ring disc, centrally guided (patent pending) (Model shown: NZF)

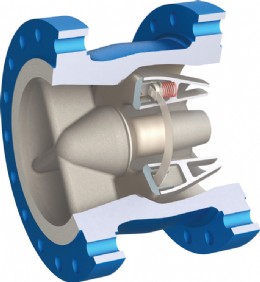

Goodwin Type N – Ring disc, radially guided (Model shown: NBF)

Check valves, to operate at their optimum performance and provide longevity of service, should operate in the fully open position to guarantee stable, chatter-free operation. Check valves that operate under partially open conditions will flutter and, in low flow conditions, chatter. Chatter, in particular, is detrimental to check valves as it causes excessive wear and, consequently, premature failure.

Compressor applications are those that present the challenge where incorrect check valve selection can have catastrophic consequences. Due to the range of possible flow conditions where low gas flowrates are a high probability, correct selection of the check valve for compressor discharge service is crucial. Low gas flowrates, with the wrong check valve, can lead to chatter and premature failure of the check valve, thereby exposing the expensive compressor equipment to significant risk of damage.

The preferred solution for compressor applications is the installation of nonslam axial (nozzle) check valves. These can withstand partial open operation more so than the non-axial types such as swing, tilting disc, and dual plate check valve types which have the highest risk of chattering under low flow conditions. However, it is still recommended the axial check valve is fully open under all flow conditions where possible.

Historically, there have been two basic designs for axial non-slam check valves: solid disc and ring disk. Both types are offered by Goodwin – the Type Z solid disc (to 10”) and the Type N ring disk (12” and larger). The Type Z solid disc is centrally guided and seated using a single spring whereas the Type N is mounted on a frictionless radial guiding system with multiple springs.

Both of these designs require large spring forces. So, to guarantee that valves are fully open in low flow conditions, particularly with the Type N, the size of the valves has to be reduced to increase flow, thereby increasing the pressure loss across the valve. This is not a desirable consequence but one of necessity to ensure stability in the low flow conditions.

To overcome this, Goodwin and Noreva has developed a new valve combining the best features of both well established designs to bring a new, globally patented valve design to market, the Type NZ.

The NZ non-slam axial check valve allows the use of much lower spring forces than the Type N permitting the valve to be fully open even at extremely low flowrates and avoiding the higher pressure losses associate with the Type N. The NZ can also have an adjustable length spacer allowing it to be tailored to be fully open under flow conditions in different applications. With its improved dynamic behaviour as a result of a very short disk stroke, the Type NZ is operationally stable even when experiencing partial flow conditions, ensuring continued and reliable protection of key infrastructure.

Tel: +44(0)1782 220000

Email: checkvalves@goodwingroup.com

Web: www.goodwinflowcontrol.com

Published: 17th November 2016

Rachel Wormald, Managing Director at YPS Valves Ltd and Elizabeth Waterman, ...

Are you looking for industry-leading, brand independent valve and actuator ...

As can be seen from the photograph, clearly the resident birds at Bartlett ...

Howco Group has unveiled its latest £1million investment, with the ...

In 2024, Allvalves is poised for an exciting year of growth and expansion, ...

GMM Pfaudler Engineered Plastics & Gaskets are delighted to bring the ...

In the ever-evolving valve industry, GMM Pfaudler stands out for its ...

SAMSON Controls Ltd – part of the SAMSON group - a renowned leader in ...