Next Generation Subsea Rotary Actuator – Product Range Extended

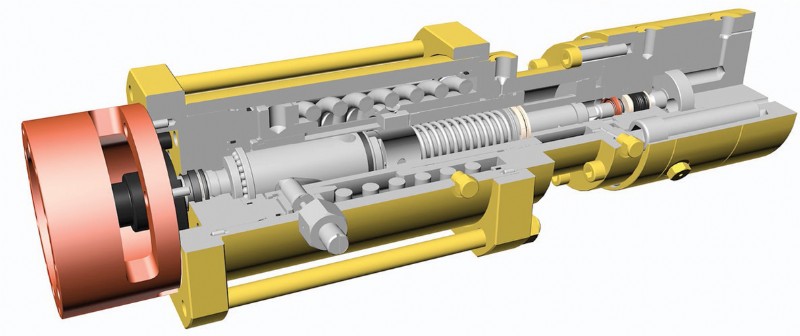

Small bore subsea valve specialist LB Bentley Ltd, part of the Severn Glocon Group Plc, has continued the development of its advanced rotary actuator, OPTItork™, by the introduction of an actuator to operate a ¾˝ ˝15k Rotary Gate Valve.

This more powerful actuator complements the ½˝ actuator launched in 2016. This larger size has been developed to meet the escalating technical demands of subsea applications and the popularity of the actuated rotary gate valve.

LB Bentley’s heritage in rotary gate valve actuators informed the work of its R&D team as it sought to refine and optimise the actuator design. The OPTItork™ is engineered to achieve requirements for both more stringent signature tests and a higher number of endurance cycles. It also has a greater available opening torque allowing it to operate on larger bore valves, operating at higher differential pressures whilst offering a reduced installation envelope.

The OPTItork™ actuators are fully certified to perform at temperatures ranging from -4°C to +66°C at installed depths of 10,000ft (3,048m) and are now available to operate the ⅜˝, ½˝ and ¾˝ LB Bentley rotary gate valves at differential pressures of up to 15,000psi (1,034bar).

“The OPTItork™ draws on decades of field experience with rotary gate valves and actuators to operate effectively and reliably in the most arduous conditions,” says Bryan Sanderson, Engineering Manager at LB Bentley. “With its reduced height, a more robust design arrangement and an increased number of fill/vent ports the actuator provides great installation versatility. This, coupled with its ‘depth insensitivity’ and capability of operating across a wide range of control pressures, ensures that the OPTItork™ offers a progressive ‘one size fits all’ solution that will meet Customer needs now and for the foreseeable future.”

A fundamental component of OPTItork™ is its helix sleeve. This has been fully re-engineered to ensure maximum torque during the opening stroke, without compromising performance on the return stroke. Internal bearings and seals have been reconfigured to achieve a performance that easily surpasses twice the number of operating cycles demanded by API 17D 2nd Ed.

For maximum durability, all essential internal sliding surfaces are nitrided for low friction and to provide a repeatable performance over the actuator’s long life. Internal hydraulic flow has been evaluated using sophisticated Computational Fluid Dynamics to ensure the actuator speed is fully self-regulated. This provides smooth, efficient and reliable operation irrespective of the how the control system operates. Finite Element Analysis, sophisticated testing techniques and data acquisition software were also used to develop and evaluate the design.

For more information and to view our OPTItork™ video, please visit our website.

Tel: +44(0)845 223 2040

Email: sales@lb-bentley.com

Web: www.severnglocon.com

| Telephone: | 01453 733060 |

| Email: | sales@lb-bentley.com |

| Website: | www.lb-bentley.com |

| More information on the LB Bentley Ltd BVAA Member Directory Page |

Search related valve / actuator articles: LB Bentley LtdIssue 41ActuatorsElectric ActuatorsElectro-Hydraulic ActuatorsRemote Control SystemsGearboxesControllersSwitchboxesGas-over-oil ActuatorsValve AutomationPneumatic ActuatorsActuator TestingMounting KitsManual ActuatorsFire ProtectionHydraulic ActuatorsCompact ActuatorsRotary Actuators