HH Valves Ltd Complete Supply of Forged Pressure Seal Check Valves into South Africa

The customer indicated a bespoke face to face requirement for the application which we were more than happy to accommodate. As these were block forgings, the addition of the extended face to face was much less of an issue from a manufacturing perspective and as no pattern modification was required we were able to keep costing to a minimum.

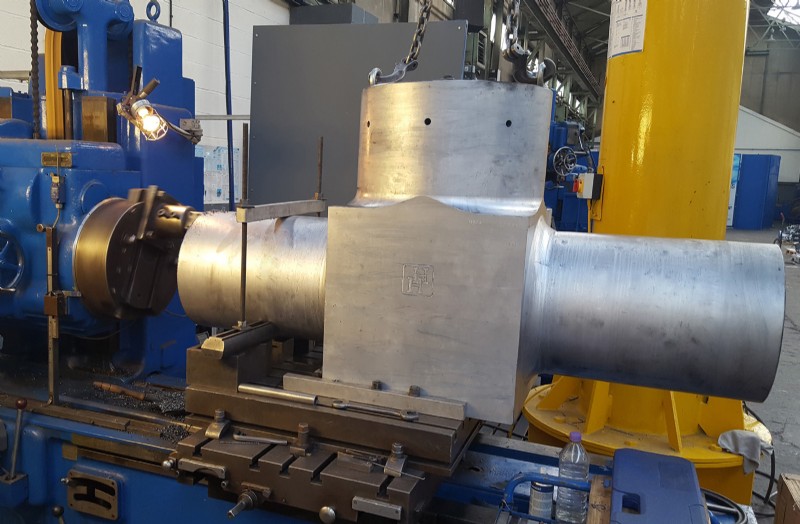

Due to the size and dimensions involved the machining of the valves tested our production capabilities to their limit but due to the experience of our engineering team we were able to complete the relevant fabrication in a safe and timely manner to the required standards and level of quality.

Downtime, replacements/repairs and a damaged reputation are at the forefront of any customers mind when it comes to issues within pipelines, valves and auxiliary equipment. The possibility for a defective casting or other potential unavoidable issues that come with a casting call for further NDE which in some cases can significantly increase the initial cost of the valve.

With HH Valves one-piece forgings, we are able to offer an increased level of material quality compared to a casting and eliminate almost all the issues that can occur during the casting process.

We pride ourselves on ensuring that our customers always receive the highest quality of product and offering our forged range alongside our traditional cast products allows our customers further peace of mind.

Further investment into our manufacturing process has enabled HH Valves to produce our large bore high-pressure range of valves, not only at comparable prices to our cast range, but also with identical lead times. This gives our customers the option of a higher integrity valve without the usual cost/delivery limitations.

Tel: 01942 218 111

Email: info@hhvalves.com

Web: www.hhvalves.com

Published: 2nd May 2018

Rachel Wormald, Managing Director at YPS Valves Ltd and Elizabeth Waterman, ...

Are you looking for industry-leading, brand independent valve and actuator ...

As can be seen from the photograph, clearly the resident birds at Bartlett ...

Howco Group has unveiled its latest £1million investment, with the ...

In 2024, Allvalves is poised for an exciting year of growth and expansion, ...

GMM Pfaudler Engineered Plastics & Gaskets are delighted to bring the ...

In the ever-evolving valve industry, GMM Pfaudler stands out for its ...

SAMSON Controls Ltd – part of the SAMSON group - a renowned leader in ...