Striking the Perfect Balance

Dynamic Balancing – are we talking the same language?

Hydronic system balancing is one of the more complicated tasks faced by building services engineers and, historically, heating and chilled water systems were only balanced by specialist engineers. However, with the availability of dynamic balancing products there is an increasing opportunity to simplify the process, cut costs and improve system efficiency.

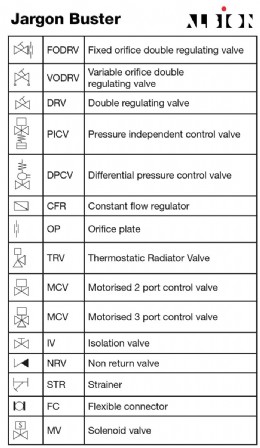

Despite these obvious benefits, some engineers are reluctant to fully embrace dynamic balancing technology – often simply because the terminology used in specifying systems differs from person to person and the numerous short-hands used can be confusing.

Here, Les Littlewood, Sales & Marketing Director at Albion Valves (UK) Ltd, provides us with a handy reminder of the principles involved, clarifies some of the jargon used and explains how to get the best out of a well-balanced dynamic system.

System balancing – understanding the basics

A ‘Hydronic’ system is simply the term used to describe a system which uses water as the medium to transfer heat, and the primary objective of any HVAC system design is to ensure the optimal level of heating and cooling throughout the building. In other words, to ensure the system is balanced.

Historically, this was achieved using a constant volume system, using ‘static’ control valves where, once set, a constant volume of water was delivered at a constant speed. Although this delivered consistent heat, it didn’t take into account the differing needs of larger commercial buildings where heat and/or chilled air were needed at varying levels in different locations – thus leading to energy wastage and less than optimal conditions for occupants.

Today a ‘variable’ volume system is the preferred approach used by most system designers, allowing, as it does, for more personalised heating/cooling control and increased energy efficiency. Admittedly, the system design is slightly more complex, but this is not something that most system engineers should fear as long as they understand the basic principles of self-regulating valves – a key component of any variable flow system.

Self-Regulating or Intelligent Valves

Self-regulating valves are, by definition, self-controlling and do not require any further input from the engineer once commissioned, instead they have the ‘intelligence’ to open and close in direct response to changes in the physical environment of the valve. This ensures the very best performance levels when set-up correctly.

For example, a Differential Pressure Control Valve or DPCV is a mechanical valve with no influence from any external control system; it will control the differential pressure as per the set-point on the valve. This can also be called a Dynamic Balancing Valve because it is adjusting to the system and maintaining its setpoint position, so it is “moving” in response to the system.

Pressure Independent Control Valves (PICVs) are also selfregulating as they operate dynamically to the system – much like a DPCV, but they also have a control actuator on them that allows the control system to interact with the valve and adjust its output to the changing needs of the system.

This is not unique to PICVs, as any control valve has this actuator feature. However, getting the best out of a PICV relies on it doing the self-regulation as well as combining several other functions at the same time. This improves its performance in relation to the circulatory system and therefore benefits system performance, energy efficiency and comfort.

Best Practice

For optimal energy efficiency and comfort control, differential pressure control valves should be used as close to the output terminals (e.g. fan coil units) as possible. However, costeffectiveness may dictate that these are only installed within network branches or sub-branches if so, balancing and control valves can be used downstream to maintain seamless performance.

Water quality could also be a consideration. Pressure independent control valves have small channels in the valve body which can easily be blocked if water quality is poor. Although strainers can be installed before each valve to remove relatively large contaminants, they will not filter very tiny particles. For this reason, it is important to assess water quality and that commissioning includes flushing the system.

Achieving optimum flow rate is also essential - too high a flow rate may cause noise, whilst too low a flow rate may not dislodge entrapped air. Flow velocities will generally be in the range of 0.75 to 1.15m/s for pipe sizes 1/2″ to 2″ and 0.75 to 3m/s for size DN65 to DN300 with pipe pressure drop per metre length generally calculated at 140 to 280 kPa.

Typically, the aim of any system is to get the balance just right and circulate the right amount of water needed to maintain optimum performance and comfort. As illustrated, self-regulating valves can play a vital role in achieving this whilst minimising waste and maximising system efficiency - which is a significant factor in striking the perfect balance.

Albion stocks a comprehensive range of products suitable for both variable and constant flow systems including Pressure Independent Control Valves, Differential Pressure Control Valves, Fixed and Variable Orifice Double Regulating Valves, Orifice Plates and Flush and By-pass Assemblies. In addition, we also offer A FREE technical guide explaining the differences between the two systems and the products and technical symbols most often used. If you would like a FREE copy, simply email Jodie Seymour: jseymour@albionvalvesuk.com or call 01226 729900. Alternatively, please visit www.albionvalvesuk.com for more details

Tel: 01226 729 900

Email: sales@albionvalvesuk.com

Web: www.albionvalvesuk.com

Published: 31st May 2019

Valveuser Magazine Issue 91 is the first of our Special Print Editions for ...

BVAA’s Director Rob Bartlett comments, “In 2024, the BVAA will be ...

Spring Conference & Golf Day, 22-23 May 2024 at Mottram Hall, ...

As 2024 is BVAA’s 85th Anniversary year, I recently had the perfect ...

The international event of reference for industrial valves and flow control ...

As long-term readers of Valveuser will know; Heap & Partners Ltd was ...

WIRRAL manufacturer Heap & Partners has recently celebrated one hundred ...

IMI has announced a record year for orders throughout the hydrogen value chain ...