Practical weight and cost savings

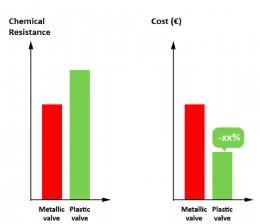

The main reasons for the success of these options is due to the extension of valve life and increase operating productivity of a pipeline, whilst being a cost-saving alternative to corrosion allowance or corrosion resistant alloys (CRA).

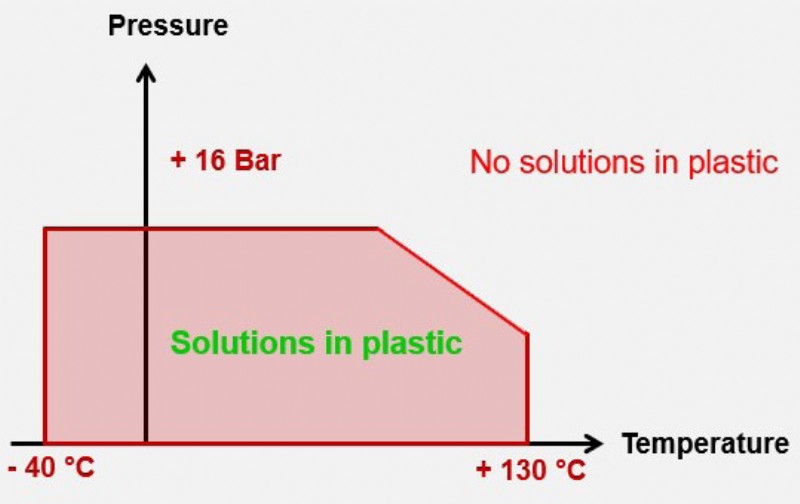

SAFI manufacture and distribute thermoplastic valves designed to work with the most aggressive envirnoments and chemicals with practical solutions for applications up to 16 bar and -20°C to +120°C.

The Oil and Gas market have many processes that require the use of chemicals and its facilities and they are often exposed to bad weather and to UV to which the SAFI valves are perfectly resistant thanks to the quality of their thermoplastics and elastomers.

Corrosion resistant metals are very expensive but working with thermoplastics isnt all about the significant cost savings, there are practical weight benefits to consider too, something that even lined metal valves cannot offer tie that in with the corrosive resistance and you are faced with a practical and wholly efficient solution.

The Oil and Gas market are not strangers to SAFI we work worldwide with brands such as Total, Shell, Petronas and AGIP who have trusted SAFI for decades when trying to find a product from our extensive product range which is suitable for their application.

The SAFI product range is suitable for the oil & gas sector in the following applications:-

Offshore platforms and on shore extractions

Electrochlorination

Waste water, drinking water, demineralized water skids

Prevention of contamination of the marine environment

Refineries

Alkilation process

Dozing plants

Scrubbers

Treatment of effluents

Chemical injection skids

FPSO

Sodium hypochlorite processing

Focus application: Sodium Hypochlorite injection into the oil wells

On FPSOs, buildings for oil exploration and exploitation, sea water and brackish water are used to put pressure on oil and are injected into the wells. Sea water needs the injection of sodium hypochlorite to avoid the contamination of marine life, the risk of scaling or corrosion in the injection lines. This bleach is normally obtained by electro chlorination on board the FPSO.

Thermoplastic valves are particularly popular on applications using sodium hypochlorite because the NaOCL is a powerful oxidant and highly corrosive. The PPH or PPGF are preferred at room temperature and PVDF in temperatures up to 60°C. Past that, sodium hypochlorite begins to decompose.

On marine installations, the thermoplastic valves also have the advantage of withstanding external corrosion. The construction of SAFI flanged ball valves adapts particularly well to the oil & gas installations which privileges flange connections.

Tel: 01202 624 618

Email: sales@safi-valves.com

Web: www.safi-valves.com

| Telephone: | 01202 624618 |

| Email: | sales@safi-valves.com |

| Website: | www.safi-valves.com |

| More information on the SAFI Ltd BVAA Member Directory Page |

Search related valve / actuator articles: SAFI LtdIssue 50ValvesSafety ValvesControl ValvesCryogenic ValvesSolenoid ValvesSafety Relief ValvesBursting DisksPilot ValvesEmergency Shut Down (ESD)Emergency Vent Valves (ESV)Butterfly ValvesPneumatic ValvesBall ValvesGate ValvesNon-Return ValvesDischarge ValvesProcess ValvesDiaphragm Valves / Pinch ValvesChoke ValvesDouble Block and Bleed ValvesCheck ValvesProtectionNeedle ValvesValve InterlocksRotary ValvesHydrantsGlobe ValvesCartridge ValvesComposite ValvesValve IslandsBreather ValvesTriple Offset ValvesPulse ValvesPress Fit ValvesIsolating ValvesBypass ValvesRadiator ValvesCapping ValvesPlug ValvesHydraulic ValvesAir ValvesAttemperatorsPressure Relief ValvesPressure Reducing ValvesSelector Valves