1939 and implications for Climate Change

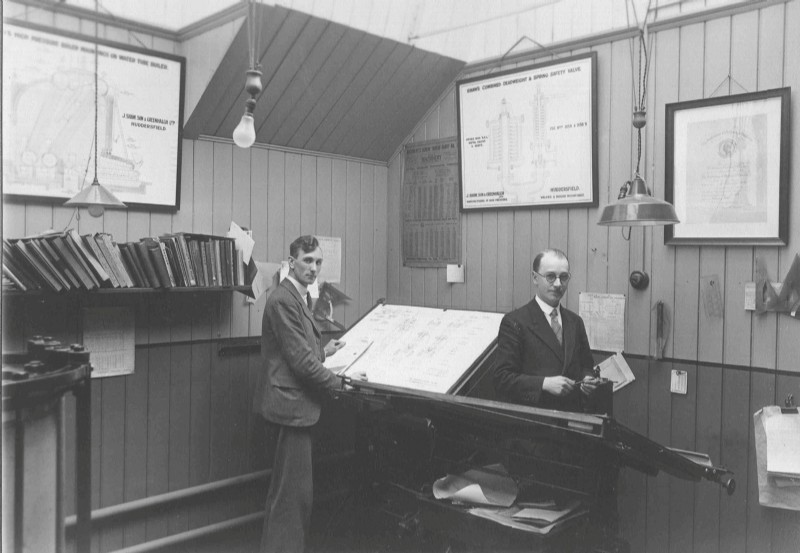

Drawing office May 1935, Shaw, Son & Greenhalgh

Toolroom May 1935

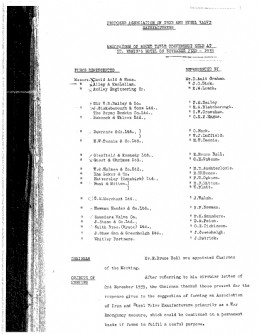

A record of the very first Valve Industry meeting

After a moment’s thought some of the more extreme demonstrators might try to draw similarities between the World War of 1939 and the war they wish to wage on governments and businesses they see as being responsible for the problem.

I believe that would be missing a lesson that our early history can teach us about the issues we face today.

Although demonstrations are important as they raise awareness and increase the receptiveness of the market to change, of themselves they do not achieve change.

At our first meeting in 1939 a key item on the Agenda was resource management. In a wartime situation there are always going to be resource shortages. Resource management is the issue that makes the connection between 1939 and reducing climate change today.

The demand for industrial valves will continue to grow because the world population is growing and individually each person wants more of the items that we can produce in our industrialised society. All of these industrial processes have ever increasing needs for industrial valves.

Therefore if we are going to have the valves to meet that demand, we must ensure that the materials to support that production are available to us. Many of the materials we use Nickel, Molybdenum, Copper, Chromium and Cobalt are already in short supply and expensive.

We must therefore be efficient in our use of these materials and we must also provision for the ability to recycle these scarce materials back into the production process.

If we do all of that, not only will we ensure we have a sustainable valve industry, we will have an impact on climate change because all of these materials take a lot of energy to produce and as result have an impact on greenhouse gases.

We are already addressing the efficiency issues by making the valves more reliable and our processes to make them more energy efficient.

But do our customers value our resource efficiency in the buying process?

I suspect not but may be that will be changing in the not too distant future thanks to the demonstrators. If our designs can be repaired and reused then that also improves efficiency of material use but for the customer is ‘buy new’ still the easy option when a valve is no longer functioning and has to be repaired or replaced?

As the manufacturer, would we prefer to sell a new valve or the spares to repair the old valve?

What happens at the end of the products useful life must also be addressed. Today the manufacturer provides no guidance on how to recover the different materials that have been used to make the valve and therefore any recycling process is likely to be inefficient in recovering the scarce materials. We need to provide guidance as to how to maximise the recovery efficiency. We need to encourage the end user to use that information or return the valve back to us for recycling in an efficient way.

Globally the UK is a small consumer of these scarce resources but we are recognised as a leader in the global valve industry. I believe the UK and therefore the BVAA must play an important role in developing ideas to conserve resources and to maximise recyclability.

I recognise that in the short term it adds costs to our businesses but, as we did in 1939, we must make decisions for the benefit of society as a whole and for the next generations.

It is job for the future leaders of our industry and one that must have our united support. I hope that they will rise to the challenge in the same way our founding members did way back in September 1939.

Martin Greenhalgh CEng FIMechE BVAA

Technical Consultant

| Telephone: | 01295 221270 |

| Email: | enquiry@bvaa.org.uk |

| Website: | www.bvaa.org.uk |

| More information on the British Valve and Actuator Association BVAA Member Directory Page |

Search related valve / actuator articles: British Valve and Actuator AssociationIssue 51BVAA NewsNews