Laser Ltd - sixty years since the revolution

Either way in 2020 Laser Technology is 60 years old. Laser has transformed Science, Surgery, Transport, Quality Control and Barcode Reading, alongside many other applications in many different sectors. It is so widely spread that no one is likely to go through a day without some form of Laser making his or her life easier.

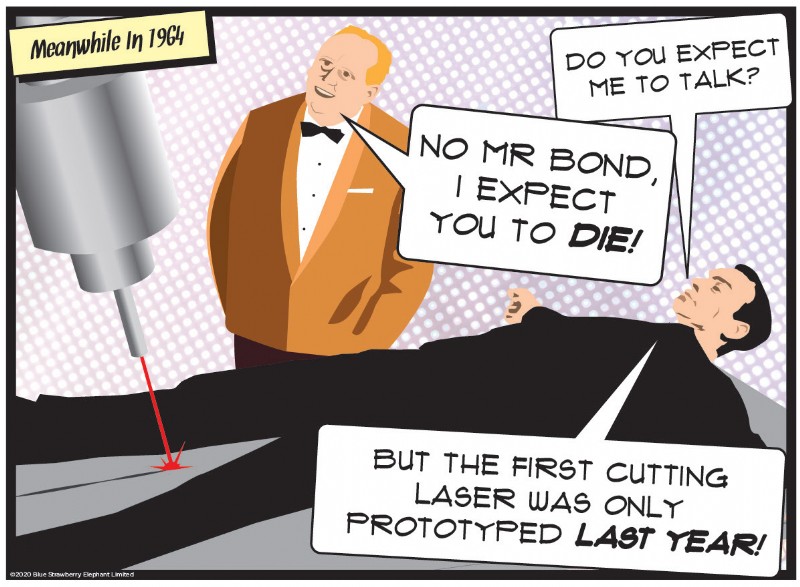

When it was invented, this technological breakthrough was so far from anything that came before it – and so far ahead of its time – that those writers of science fiction and thrillers jumped at the chance to use it in their stories; a sure sign of a revolution in the making.

And so it proved to be; in many more ways than were even dreamt of back then.

Theodore H. Maiman, was working for the Hughes Research Laboratory in Malibu California when he demonstrated the first practical laser machine in 1960. The dedicated laboratory was the research arm of Hughes Aircraft, founded in 1932 by the famous industrial visionary Howard Hughes.

The two large white buildings of its current incarnation still overlook the Pacific, where work carries on advancing the descendent tech for its current owners GMC and Boeing. The next incarnation came very quickly when in 1961 Kumar Patel started working at Bell Labs and by 1963 had developed the first cutting Laser.

In such a relatively short space of history, Laser has become so embedded within the English language it is hard to believe that the word itself didn’t exist before it became the acronym for Light Amplification by Stimulated Emission of Radiation.

It is these pioneers to whom we owe our industry.

Even the very latest machines at Laser Limited aren’t suitable for scanning credit cards or carrying out Eye Surgery, but they do cut sheet metals to extremely fine tolerances, with multiple advantages over mechanical cutting and drilling; not only in precision terms but also due to the lack of contamination from physical cutting tools and edges.

The much smaller heat effected zone vastly reduces the chance of warping thinner sheet materials - and as Laser beams don’t wear out there is zero opportunity for a production run to have the Quality Control issues that may occur when a mechanical tool isn’t changed over soon enough to avoid exceeding the range of tolerance demanded.

Of the options available for Laser Cutting we chose to equip with Fibre Laser because we wanted to offer as flexible and wide ranging a service as possible; allowing our clients to source components in different metals from one company.

Other Laser cutting technologies were not suitable for more malleable sheet materials with lower melting points - such as Copper or Brass.

The focussed beam of our state of the art Fibre Cutting Laser Machines can reproduce any design specified for manufacture in, but not restricted to, Mild Steel up to 20mm thick, Stainless to 16mm, Aluminium to 12mm and Copper or Brass to a thickness of 4mm.

Work handling is also much more efficient on our Laser beds, the travel and turning of our Lasers and the sheet metal being cut is directed by CNC software which combines with CNC Braking when the components being produced need to be folded - before, after or simultaneously with the Laser cutting process.

The QK Group has invested heavily in Laser Limited’s dedicated staff and next gen equipment, to give our manufacturing clients the very best service available – but it doesn’t stop there – not only in California but also around the world, Laser technology has advanced in every one of its 60 years.

We expect that development to continue – eventually overtaking the powerful Plasma Cutting tech, which is currently one of the only options for cutting much thicker sheet steels. When that happens our services to design engineers will allow them to create virtually anything.

Tel: 01623 515 545

Email: sales@laser-online.co.uk

Web: laser-online.co.uk

Published: 18th February 2020

Rachel Wormald, Managing Director at YPS Valves Ltd and Elizabeth Waterman, ...

Are you looking for industry-leading, brand independent valve and actuator ...

As can be seen from the photograph, clearly the resident birds at Bartlett ...

Howco Group has unveiled its latest £1million investment, with the ...

In 2024, Allvalves is poised for an exciting year of growth and expansion, ...

GMM Pfaudler Engineered Plastics & Gaskets are delighted to bring the ...

In the ever-evolving valve industry, GMM Pfaudler stands out for its ...

SAMSON Controls Ltd – part of the SAMSON group - a renowned leader in ...