GEMÜ 550 Globe Valves in Sugar Centrifugation

Continuously Operating Centrifuges

Figure 1_GEMU 550 in foreground with centrifuge filling device behind it

Figure 2_GEMU 550 for distribution of steam and water

Figure 3_Centrifuge diagram

Figure 4_GEMU 550 with 1434 positioner

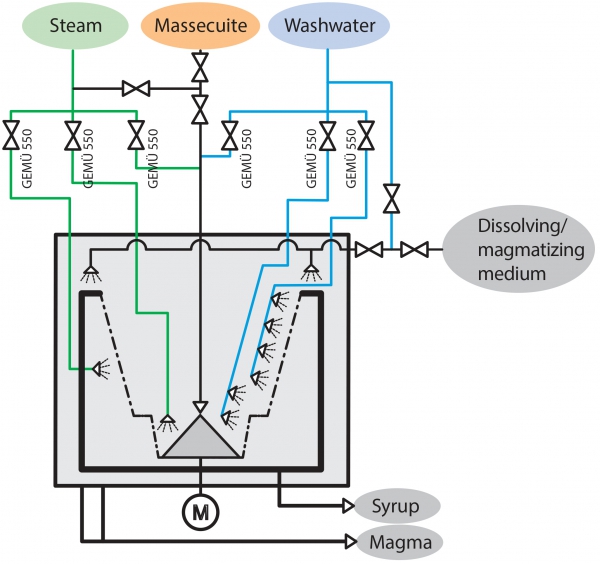

Continuously operating centrifuges are used to separate the crystalline suspension of sugar from its mother liquor. The sugar can then be redissolved in the centrifuge before being fed into a further processing stage. In this process, GEMÜ 550 globe valves reliably regulate the feed of wash water and steam into the centrifuges via a GEMÜ 1434 digital positioner to precisely control the media flows.

Overview: Centrifugation of Sugar

The sugar beet cossettes are mixed with hot water in extraction towers to extract the sugar contained in the cells of the beet. This produces the raw juice. Burnt lime and carbon dioxide are added to precipitate the non-sugar substances from the juice, which are then filtered out. The resulting thin juice contains roughly 16% sucrose and is bright yellow. After several successive evaporation phases, the juice thickens, which by this time is golden brown and viscous (roughly 70 to 75%). More water is then removed under vacuum and the application of heat in vacuum pans. Here, the water starts to evaporate under vacuum at just 65 to 70°C as these low temperatures reduce the colour change during the crystallisation process. Crystals start to form in the supersaturated sugar solution upon the addition of fine sugar crystals which act as seed crystals. The resulting crystalline suspension is known as massecuite. Crystallisation is performed in several steps to achieve an optimal sugar yield. In the final crystallisation step, the crystalline suspension is also cooled further in the cooling crystallisers. This results in further crystal growth. The cooling process takes place under continuous movement to prevent settling of the crystals. Next, the liquid part of the crystalline suspension is separated from the crystals in continuously operating centrifuges. To obtain particularly pure sugar, the crystals are dissolved in water again and then re-crystallised.

Centrifugation of the Massecuite

In order to separate the syrup from the crystals, batch centrifuges and continuous centrifuges are used depending on the purity of the massecuite. In the case of continuous centrifuges, the highly viscous massecuite is channelled from the distribution mixer via the filling device and into the centrifuge with the addition of water and steam. Depending on the consistency of the massecuite, the crystals are then separated from the syrup at approx. 1500 to 1900 rpm. The addition of water and steam serves to reduce the viscosity and thus facilitate separation.

Within the product distributor of the centrifuges (inner area of the basket), the media are first intensively mixed, uniformly distributed and accelerated. The basket becomes conical towards the top, which causes the crystals to move upwards on the inner wall to the edge of the basket.

From the distribution bell of the product distributor, the massecuite then enters the preliminary separation stage of the basket, in which already a large part of the mother liquor is separated from the crystals. The sugar crystals are held back on the screen. As the diameter increases, the centrifugal force increases together with the separating effect. The remaining mother liquor is washed from the crystals by the addition of water through the jets installed in the centrifuges. The right quantity of water is extremely important to avoid unnecessarily dissolving of the crystals. Once the cleaned crystals have reached the end of the basket, they enter the sugar chamber and then a transportation device.

GEMÜ 550 with 1434 Digital Positioner

The GEMÜ 550 actuated angle seat globe valve is ideally suited for CIP, SIP, condensate and water applications. In this application, GEMÜ 550 globe valves with 1434 digital positioners are used to control the supply water and steam during centrifugation. The valve spindle is sealed by a self-adjusting gland packing providing reliable valve spindle sealing even after a long service life with high cycle duties. The valve positioner consists of a robust and compact housing with transparent cover in which the controller, travel sensor, switching valves and LEDs for status indication are integrated. A compact and extremely cost effective package for media flow control.

Tel: 01925 824044

Email: enquiries@gemu.co.uk

Web: www.gemu.co.uk

| Telephone: | 01925 824044 |

| Email: | sales@gemu.co.uk |

| Website: | www.gemu.co.uk |

| More information on the Gemu Valves Ltd BVAA Member Directory Page |

Search related valve / actuator articles: Gemu Valves LtdIssue 54Globe Valves