GEMÜ – Putting You in Control!

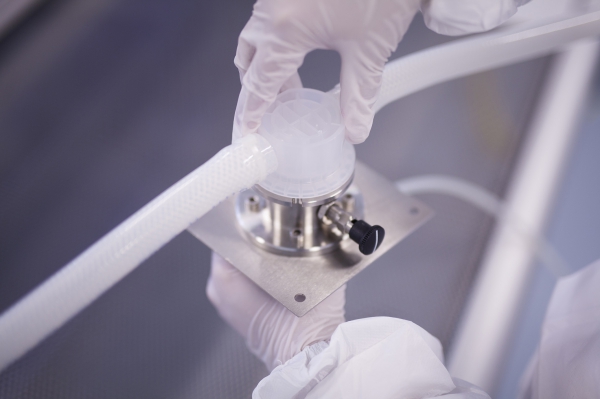

The World’s First Single-Use Diaphragm Valve

The application of Single-Use disposable products within pharmaceutical process engineering has grown at a phenomenal rate over the past few years. The ability to have pre-prepared sterile production equipment that can be installed, run and disposed of quickly enables Pharmaceutical manufacturers to produce fast, safe, and flexible batch production. Reaction times are faster for production, equipment is already sterile so no cleaning is required and production can begin immediately and safely.

After completing a batch, significantly less time is needed to replace the Single-Use disposable products than is required for cleaning and sterilisation processes (CIP/SIP) in a conventional stainless steel plant. This reduces not only the investment costs of such a plant, but also eliminates the time-consuming cleaning validation of the piping system components which is no longer required for Single Use systems.

Single-Use processes are safer due to the reduced risk of cross contamination and other influencing factors such as costly cleaning. Contract Manufacturing Organizations (CMOs) can also benefit from using a Single-Use plant. If they are commissioned by large companies to produce smaller than normal quantities of a product, or to produce products within a short period of time, they can now respond flexibly to customers’ needs and specifications. In the manufacture of small batch sizes up to approx. 2,000 liters, which are also often required in research and pilot production systems; Single-Use equipment is increasingly being used.

Single-Use processes and technology are undoubtedly making an important contribution in helping to overcome global challenges in the healthcare sector, particularly in controlling the rapid spread of infectious diseases and in the case of pandemics where time lost is critical, as it can affect the number of lives saved.

Single-Use plants allow for new biopharmaceuticals and vaccines to be brought to the market faster. The fact that pathogens are becoming increasingly resistant to antibiotics is another reason why new pharmaceuticals and treatment options continuously need to be developed at a fast pace aided by Single-Use processes.

For more information, visit: https://www.gemu-group.com/gemu-cdn2/dokumente/29/bs_p_042_product_flyer_sumondo_gb.pdf

Tel: 01925 824044

Email: enquiries@gemu.co.uk

Web: www.gemu.co.uk

Published: 29th October 2020

Rachel Wormald, Managing Director at YPS Valves Ltd and Elizabeth Waterman, ...

Are you looking for industry-leading, brand independent valve and actuator ...

As can be seen from the photograph, clearly the resident birds at Bartlett ...

Howco Group has unveiled its latest £1million investment, with the ...

In 2024, Allvalves is poised for an exciting year of growth and expansion, ...

GMM Pfaudler Engineered Plastics & Gaskets are delighted to bring the ...

In the ever-evolving valve industry, GMM Pfaudler stands out for its ...

SAMSON Controls Ltd – part of the SAMSON group - a renowned leader in ...