Emerson ASCO: Reliable solenoid valves essential for safety in critical applications

If solenoid valves do not operate correctly when required, the consequences can be catastrophic. Thierry Filley, vice president of engineering, ASCO fluid control products at Emerson, explains the valve design considerations for maximising operational reliability and process safety

Solenoid valves operate on the principle that an electrical signal creates a magnetic force which opens or closes the flow section (orifice) of the valve to enable, stop or divert the fluid flow in a pipe. During their lifetime, solenoid valves can perform millions of cycles. At the opposite end of the scale, such as when used within Emergency Shutdown applications, they may only need to operate a handful of times over their entire lifetime.

But even after lengthy periods of dormancy when in standby mode, it is essential that solenoid valves can be relied on to operate correctly when required to do so. Even in less-critical applications, if the solenoid valve fails to operate and the process valve remains inactive, this can affect process control, efficiency, and product quality, and can also result in unscheduled downtime, which can be both inconvenient and extremely costly.

Sealing technology

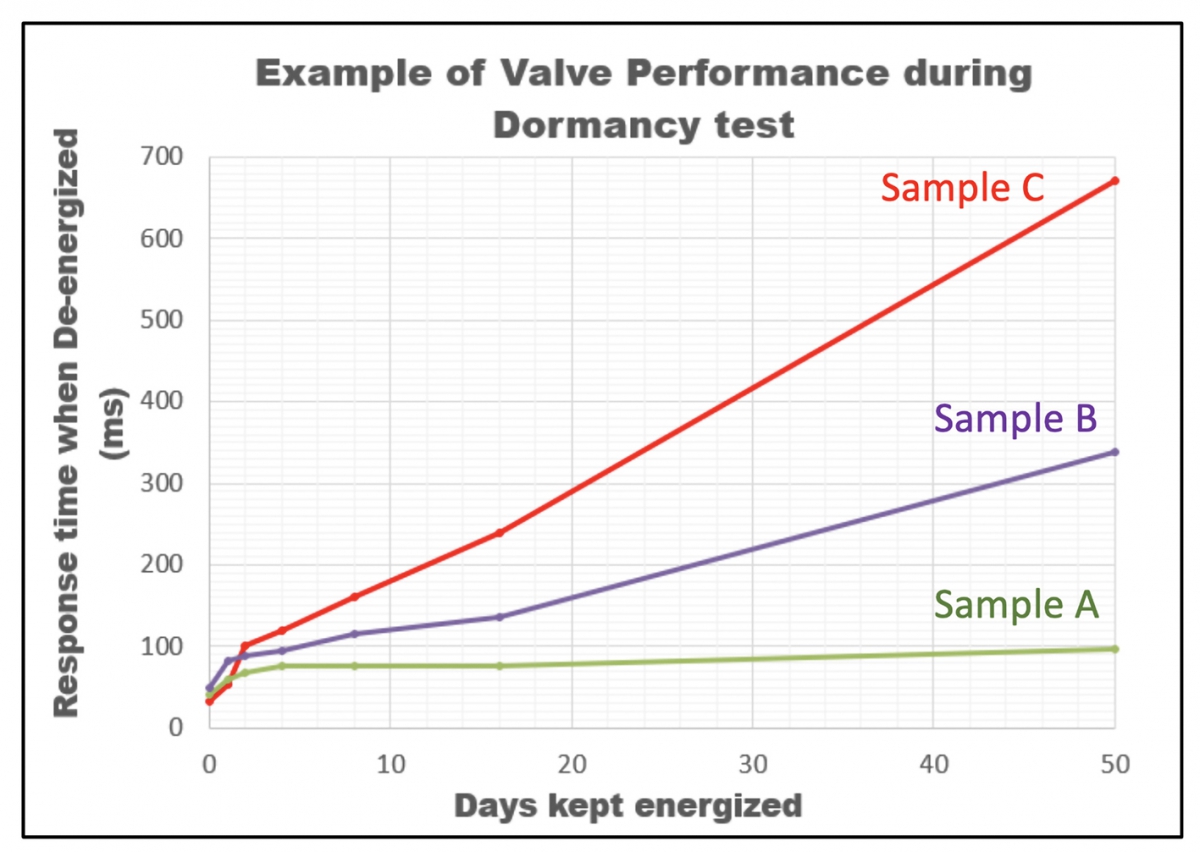

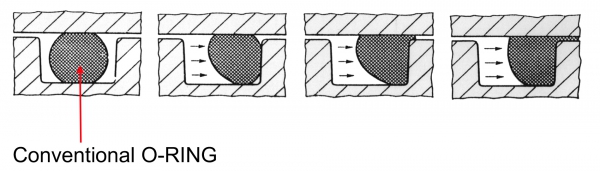

When selecting a solenoid valve there are certain critical differences in the design that will impact its performance in dormancy and its long-term reliability. For example, conventional solenoid valves have a design that uses O-rings to provide valve stem sealing that prevents leakage, but this type of design can cause increased friction. This increases the risk of sticking, especially after a period of dormancy, thereby affecting valve reliability and safety.

The sealing ability of O-rings reduces over time due to the deterioration of the elastomer, which creates the opportunity for fluid to escape. Contaminants in the fluid can then accumulate on the valve stem. This increases friction, which can result in slower response times. Ultimately, leaking seals can lead to dangerous failures if they prevent the solenoid valve from returning, and the safety process control valve does not respond. O-rings can also deform under certain conditions, compromising their ability to seal or cause them to extrude into the narrow gap between the components. This can cause increased friction or damage to the O-ring.

Some solenoid designs incorporate a breathing hole as a means of attaining smoother movement. However, that exposes the valve internals to contaminants from the atmosphere, which can build up on the stem and increase friction. Conventional solenoid valve designs that have O-rings for valve stem packing and breathing holes represent considerable risk. It is important therefore that solenoids have designs that reduce friction and prevent sticking.

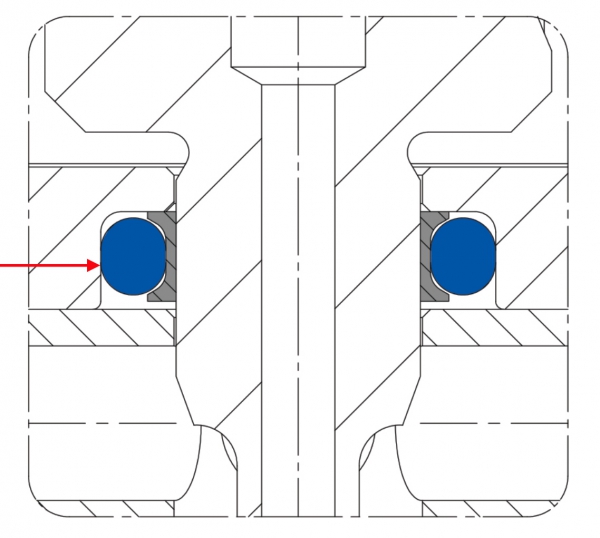

Two-layer dynamic seal

Designs that use a two-layer dynamic seal avoid the elastomer coming into contact with the valve stem. The inner layer seal (U-ring), which is in contact with the valve stem, can instead be made of polytetrafluoroethylene (PTFE) and supported by an elastomer O-ring. The type of elastomer used for O-rings is medium-resistant, energises the PTFE U-ring, and provides static sealing. In combination with a valve stem that is polished to a micron level surface finish, this design prevents any sticking and minimises friction on the stem.

The risk of sticking is also reduced by the elimination of breathing holes. ‘Non-breathing’ valves do not allow ingress of dirt from the atmosphere and are consequently more likely to have stable friction and operate when required.

Low and stable friction

In terms of reliability, low and stable friction is one of the most important parameters considered within solenoid valve design. For a valve to function correctly, the actuation force must be greater than the friction, and different applications will demand a specific ratio (calculated by dividing force by friction) to ensure that the valve will operate as required. However, varying solenoid designs can achieve the same ratio in different ways. In designs that produce a relatively high amount of friction, a greater force is required to achieve a certain ratio, while in designs that generate less friction, a lesser force is needed to attain a comparable result. For example, a spring force of 60N and frictional resistance of 4N would result in a factor of 15, but a spring force of 15N and frictional resistance of 1N would also produce a factor of 15.

This illustrates that devices offering greater force are not necessarily better. In fact, although both design types can achieve the same factor, there are advantages to selecting a solenoid valve with a design that produces low force and low friction. These designs enable stability to be maintained over time, providing greater peace of mind. Also, maintaining friction stability reduces maintenance requirements and enables users to safely extend the period between proof-tests to between five and seven years, while remaining compatible with their desired safety integrity level. In a facility with hundreds or even thousands of valves, this creates substantial benefits in terms of saved worker time and reduced operational costs.

The coil and return spring

The design of the solenoid valve electromagnet, including the coil and return spring is another important consideration. The coil is fundamental to the operation of a solenoid valve and has a significant impact on its reliability. The coil creates a magnetic force that lifts the core/armature to either open or close. Without the coil, the internal components cannot be moved when energised. If the coil fails, the valve fails. In order to overcome increased friction caused by sticking seals, some manufacturers will use a stronger spring force so that as the friction increases the valve will still operate. This requires a higher-powered coil, but as the power increases more heat is generated which can negatively affect the lifetime of the solenoid.

Failing coils can lead to spurious trips that shut down the process. Valves with a low friction seal design eliminate the need for a high spring force and can therefore be more compact and allow for a low power coil to be utilised. This means that new solenoid valves can be installed more easily, without having to upgrade power cabling or add more power supplies. As such, a low power coil makes it possible to energise more solenoid valves with the same or smaller infrastructure, such as smaller power supplies and thinner cabling. Lower power coils also make it possible to use the least expensive DCS/SIS output channels without intermediate relays. An added benefit is that as lower power equals lower temperature, this promotes a longer operating life and higher explosion safety, whilst reducing operating costs.

Residual magnetism

Another important design consideration when selecting solenoid valves is how effectively they can overcome the issue of residual magnetism. The metal parts of solenoid valves retain magnetism after operation, even when the valve has been de-energised, and if this residual holding force becomes too great it can cause the valve’s plunger to stick, preventing it from moving back into position. Valves must be designed to reduce the impact of residual magnetism. This can be achieved by incorporating the presence of a permanent air gap – even when the valve is energised – that minimises any risk of sticking caused by residual magnetism.

Conclusion

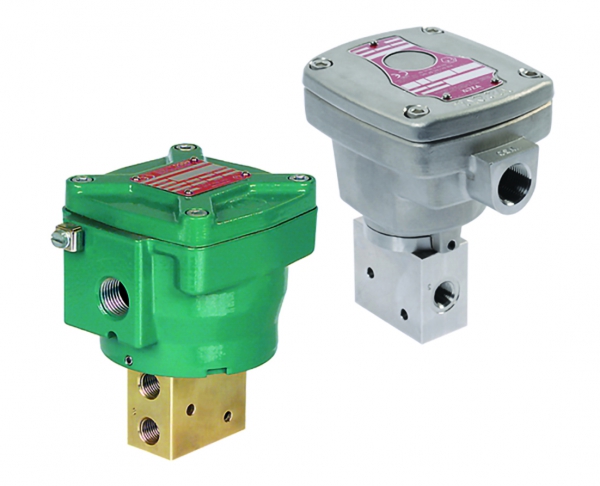

All of these design features must be taken into consideration when selecting the right solenoid valve for your application, but not all solenoid valves can satisfy every design requirement. Ideally, you should select a proven safe and reliable solution that can withstand even the most demanding process industry environments. It is important for solenoid valves to have strong safety accreditation, to be explosion-proof and meet and even exceed the stringent requirements of demanding sectors such as oil and gas. They should also have robust build quality to ensure reliable operation, along with a non-breathing design, low friction seal construction and extended coil life to make them inherently reliable, helping ensure the long-lasting safety of the application. Valves that can provide these features, such as the ASCO™ Series 327 solenoid valve from Emerson, can dramatically reduce engineering time and commissioning costs.

www.emerson.com/en-us/automation/valves-actuators-regulators/solenoid-valves

Email: enquiries.asco.uk@emerson.com

Website: www.emerson.com

Search related valve / actuator articles: Emerson Automation Fluid Control & Pneumatics UK LtdIssue 60Solenoid Valves