GEMÜ: Dosing Installations for Detergent in Industrial Laundries

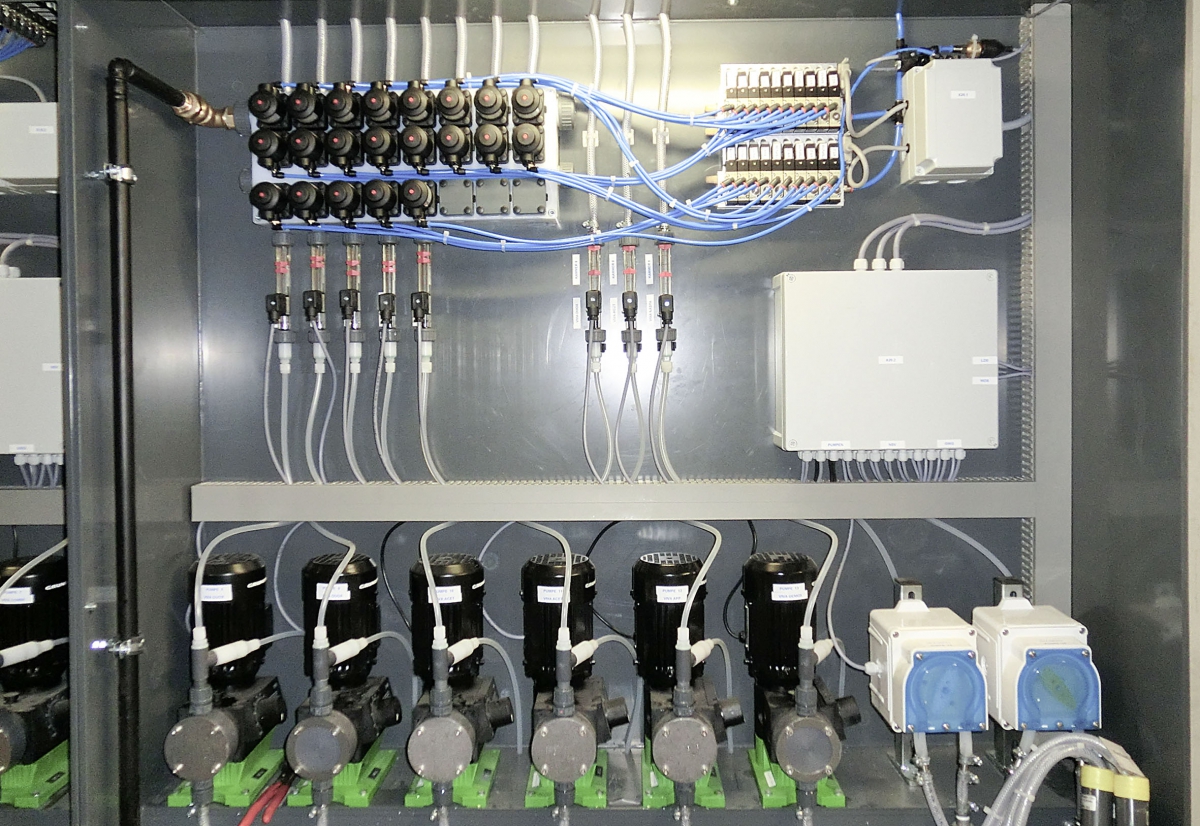

Figure 1 - Dosing Cabinet

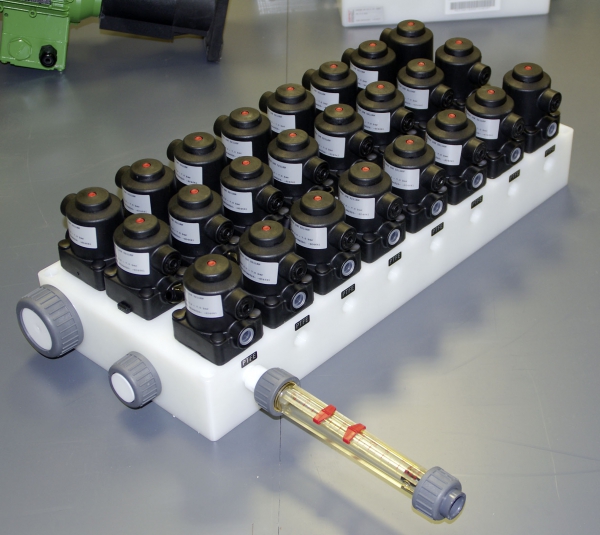

Figure 2 Multi port valve block with flowmeter for detergent dosing and distribution

Figure 3 Extendable multiport valve block

Extendable GEMÜ Plastic Multi-port Valve Blocks

In a successful industrial laundry applications, the GEMÜ plastic multi-port valve blocks are used to produce a wide variety of detergents and automated systems for dosing these detergents. The compact GEMÜ plastic M-Blocks are the key element in these systems as they make the corresponding dosing, distribution and flushing functions possible.

Operation of detergent dosing installations

Automated detergent dosing installations provide industrial laundries with flexibility, allowing them to adjust the required detergent composition individually to each specific cleaning programs. Depending on the hardness of the water and the type and level of soiling, the cleaning agents, special additives and care products can be dosed to match the type of textile being washed.

In the case of conventional dosing installation designs, a separate dosing pump is required for each washing machine and medium. The resulting large number of pumps, hoses, unions and distribution components makes extensive maintenance and calibration work necessary.

Compact design improves plant reliability

The use of GEMÜ multi-port valve blocks allows the number of pumps, hoses and fittings to be kept to a minimum on modern dosing installations. Only one pump is required per medium and multiple washing machines can be supplied with one dosing installation. A smaller number of connection points improves plant reliability as it reduces both potential leakage points and deadleg. Less connections mean less time required to assemble the customized units. All these benefits make a significant contribution to cost optimization of the plant.

Multiple functions in one multi-port valve block

In order to achieve a more compact design, all dosing, distribution and flushing functions are combined in one multi-port valve block. The dosing pump for each medium is connected to a variable area flowmeter each of which is connected directly to the multi-port valve block. The valve block consists of 3 rows of pneumatically actuated diaphragm valves. The first valve row at the bottom is used to dose the medium. Depending on the requirements, quantities of 10 – 200 ml are metered out. The valves in the second row control which washing machine the medium is sent to and the upper, third row of the valve block is used to flush the unit with water after every dosing process.

Expandability of existing plants

The multi-port valve blocks are also able to be extended. If an industrial laundry adds washing machines to its plant, the existing dosing unit can be extended by the required number of valves with just a few simple modifications without the need for additional piping, solvent cemented joints or welds.

For more information, click here.

Tel: 01925 824044

Email: enquiries@gemu.co.uk

Web: www.gemu.co.uk

| Telephone: | 01925 824044 |

| Email: | sales@gemu.co.uk |

| Website: | www.gemu.co.uk |

| More information on the Gemu Valves Ltd BVAA Member Directory Page |

Search related valve / actuator articles: Gemu Valves LtdIssue 68Diaphragm Valves / Pinch Valves