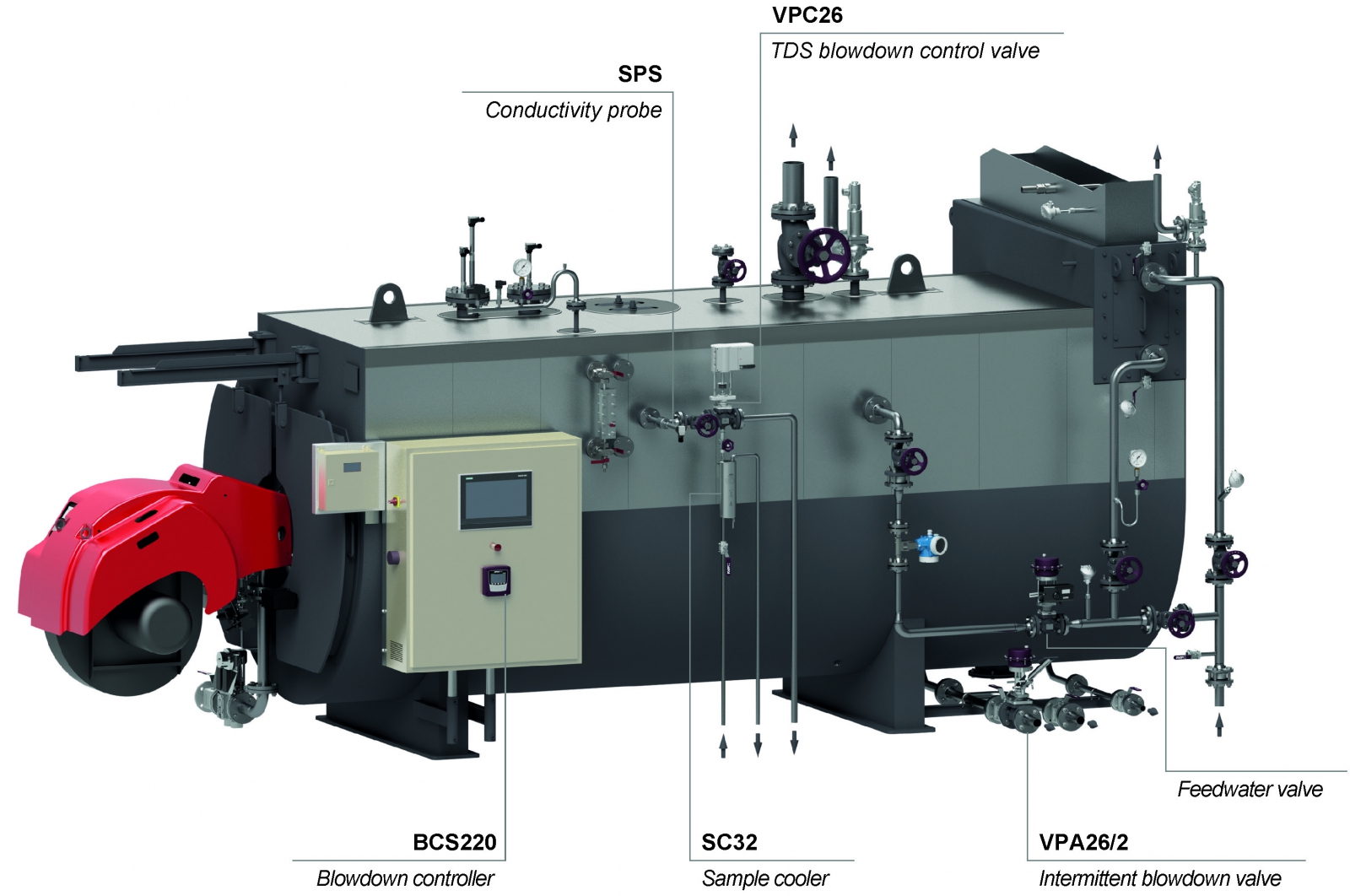

ISIS Steam provides complete TDS blowdown solution

When a steam boiler is in operation, there is continuous evaporation of boiler water which causes an undesirable increase in TDS (Total Dissolved Solids) concentration. A typical problem that results from this is water foaming, which leads to reduced boiler performance, wet steam and worst of all false water level alarm readings. Furthermore, dissolved and suspended solids will carry over into the steam lines, contaminating valves, tubes, heat exchangers and steam traps, leading to corrosion, scaling and erosion. For these reasons, a certain amount of boiler water must be discharged continuously or periodically to ensure TDS concentration is kept within the recommended parameters. The TDS system is composed of blowdown valve, conductivity probe and controller.

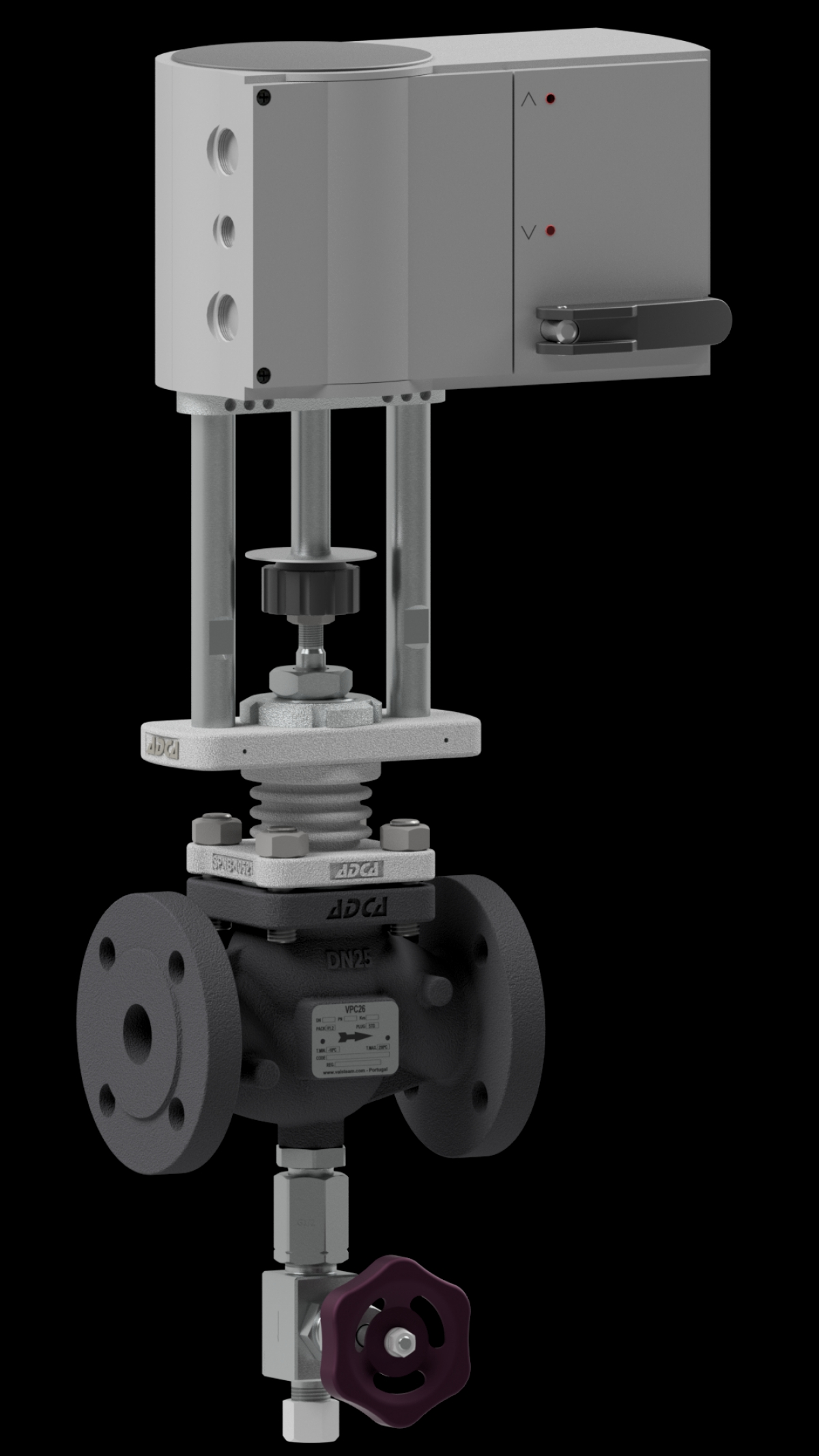

The ADCATrol VPC26 is our latest TDS blowdown valve. The valve features a clamped-in seat system and an axial multi-stage trim, which progressively reduces the energy of the fluid. With a fully guided valve plug and stellite facing to improve wear resistance, the valve is ideal for discharge of boiler blowdown at high differential pressures where flashing is a concern. To complete the set of features, the valve can be supplied with a bottom connection for the installation of a sample valve, to ease the process of sampling the boiler water. Valsteam ADCA also offers a range of sample coolers to suit.

To complement the VPC26 blowdown valve is the all new ADCATrol BCS220 blowdown controller. This device takes care of both TDS and intermittent blowdown controls in a compact enclosure ready for surface mounting with IP66 NEMA 4X protection. This feature is particularly useful when retrofitting into existing boilers as the unit does not need to be installed into an existing control panel. The controller includes various blowdown functions including a pulsed mode, which slows the rate at which the boiler water is removed avoiding the risk of triggering a low water alarm. A sampling mode for inline conductivity measurement is also featured to ensure measurement at boiler temperature without wasting energy with by-passes.

The new controller is universal and can be used not only with any ADCATrol SPS series of probes but also with most other conductivity probes on the market. Temperature compensation can be set manually or automatically through an RTD sensor input.

For further information, please contact ISIS Steam the UK partner for Valsteam Adca.

Email: sales@isissteam.com

Tel: 01608 645755

Website: www.isissteam.com

| Telephone: | 01608 645755 |

| Email: | sales@isisfluid.com |

| Website: | https://www.isisfluid.com/ |

| More information on the Isis Fluid Control Ltd BVAA Member Directory Page |

Search related valve / actuator articles: Isis Fluid Control LtdIssue 79Valves