SmartMarker® - unique identifiers for plastic products

SmartMarker® for plastic identification

SmartMarker® plastic from Rochling

BRANDPROOF® Reader

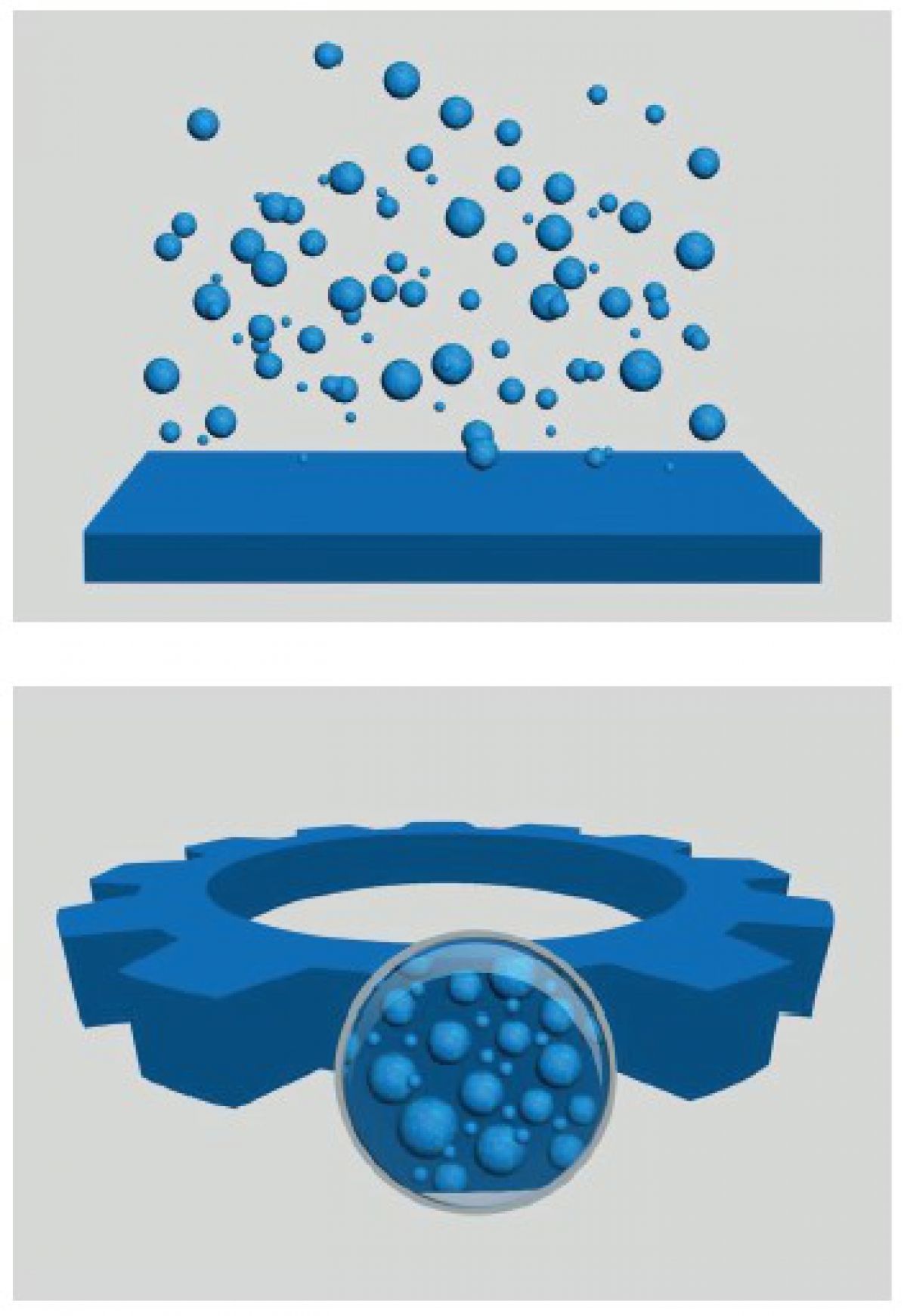

Röchling Industrial incorporates a specially adapted marker into semi-finished plastic products at the point of manufacture. Components machined from the material bear the distinctive marker and can be clearly authenticated or identified.

SmartMarker® offers completely new options in the development of digital material passports, info for recycling, and counterfeit protection, and can be used to optimise many processes.

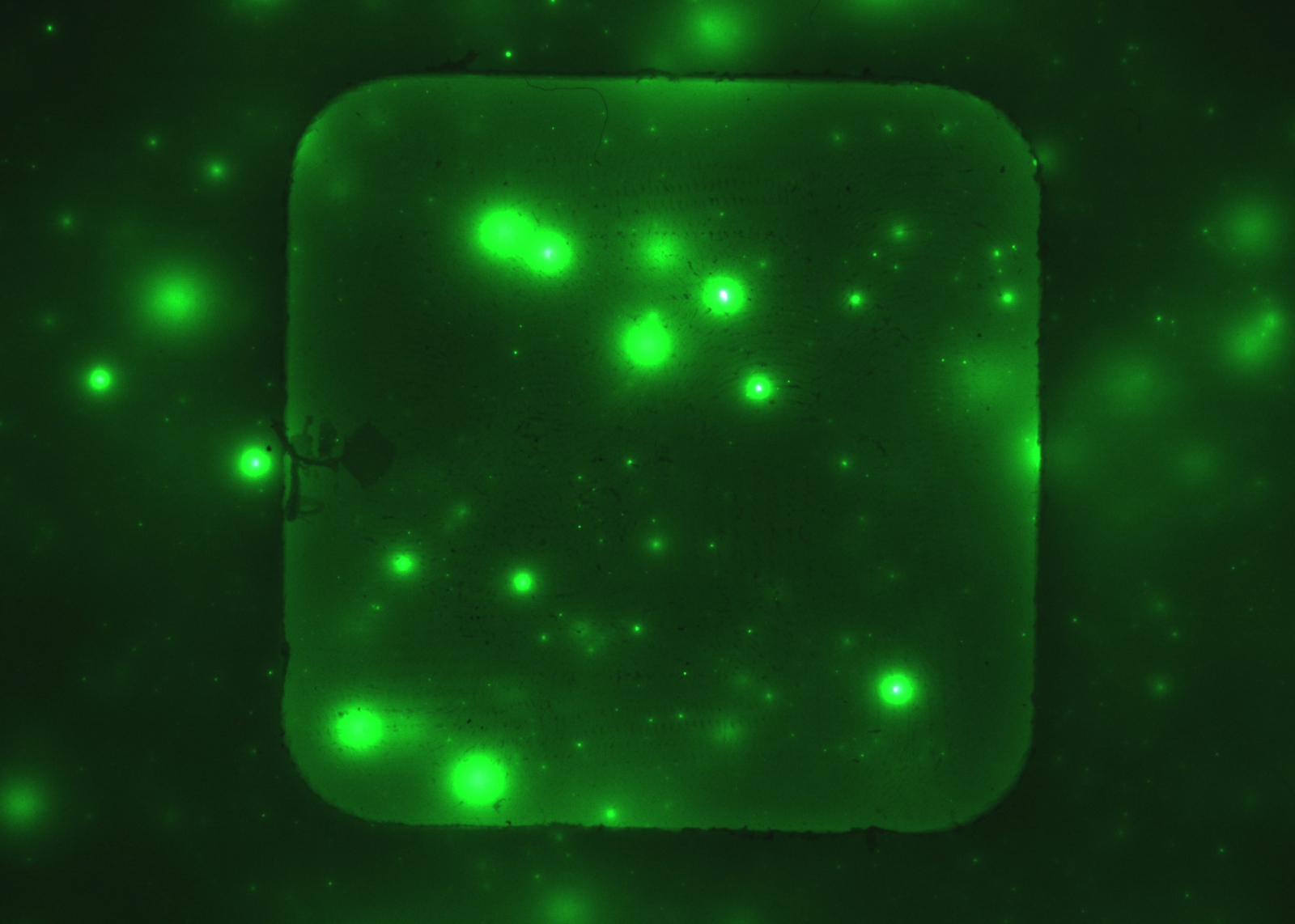

Dr. Axel Höfter, General Manager Corporate R&D Röchling Industrial, explains: "We give our plastic products a distinctive identifier made of tiny marker particles. The markers are invisible and do not affect the technical properties of the material. Every component complies with our high standard technical requirements."

Authentication

During authentication, the marker can be used to prove which company manufactured a component. A mobile BRANDPROOF® pocket detector is used to scan any part of the component. If the component contains the marker, this proves the origin of the product.

Authentication can be used to optimise counterfeit protection and the prevention of unjustified complaints.

Particle fingerprint identification

A marker can be used to determine whether a specific component is involved. For this purpose, a reference surface is created on the component. This reference surface contains a random, and thus individual, irreproducible particle pattern. The pattern gives the component an unmistakable particle fingerprint.

Creation of product passes

SmartMarker® can also be used to create digital product passports. The particle fingerprint can be digitised and stored in databases. Röchling customers can save further product and quality-relevant information for their fingerprint – such as material properties, customer information and batch numbers.

Tracer-based sorting

Tracer-based sorting (TBS) is a sorting technology that detects markers in plastics. This opens up new options in the development of recycling systems. Tracer-based sorting can be used to sort plastic recycling efficiently and reliably.

Tel: 01298 811800

Email: sales@roechling-fibracon.co.uk

Website: https://www.roechling.com/uk/industrial/high-peak

Published: 6th December 2022

Rachel Wormald, Managing Director at YPS Valves Ltd and Elizabeth Waterman, ...

Are you looking for industry-leading, brand independent valve and actuator ...

As can be seen from the photograph, clearly the resident birds at Bartlett ...

Howco Group has unveiled its latest £1million investment, with the ...

In 2024, Allvalves is poised for an exciting year of growth and expansion, ...

GMM Pfaudler Engineered Plastics & Gaskets are delighted to bring the ...

In the ever-evolving valve industry, GMM Pfaudler stands out for its ...

SAMSON Controls Ltd – part of the SAMSON group - a renowned leader in ...