DRB Group – Investment in Growth

Investing to support our customers’ future growth

We know that any downtime in a production line is costly to a business.

We understand the challenges faced by our customers to continue to improve production efficiency and reduce downtime. Our investment in new machinery, which include the Doosan SMX 3100 and Doosan VM 750L will enhance our machining capabilities and ability to produce more complex engineering components, to meet the challenges faced by our customers.

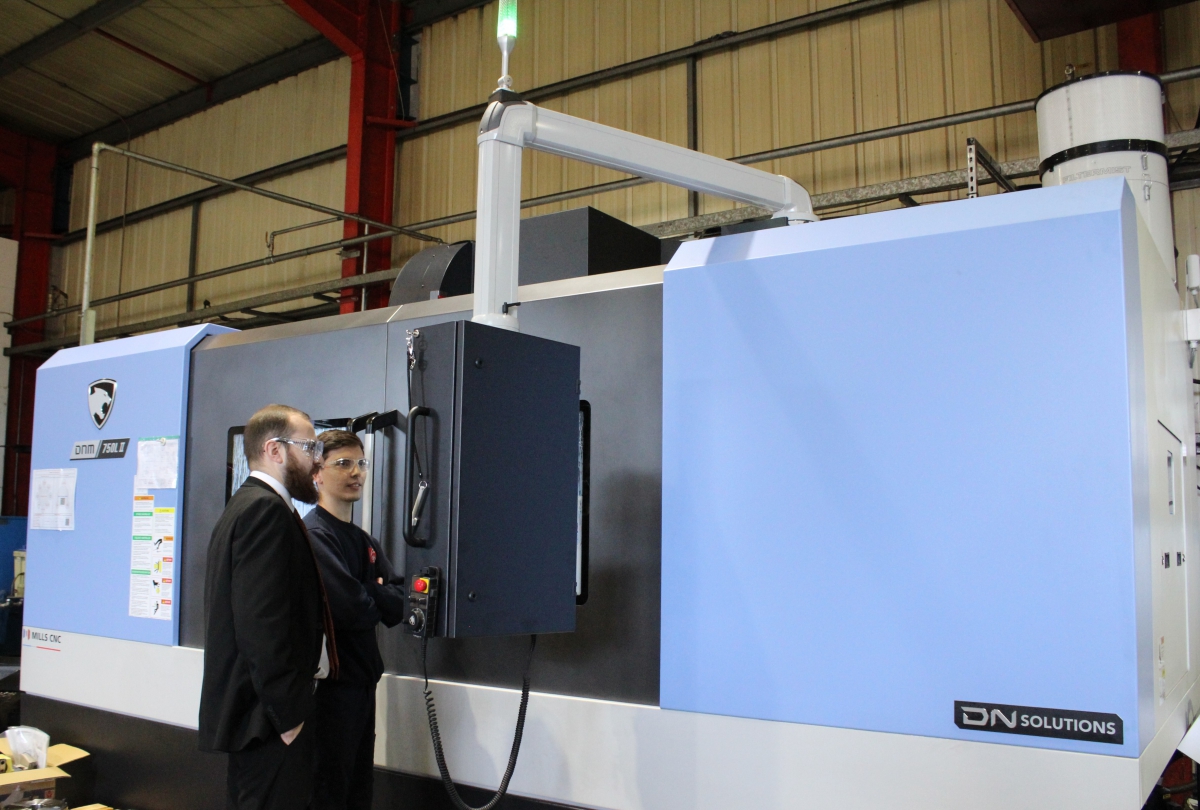

We were therefore delighted to welcome Jack Sargeant (MS) to DRB Group, who was keen to view the latest CNC Machine investment DRB Group have made and the additional capabilities these provide.

After taking delivery of our two new Doosan CNC machines: SMX3100 mill-turn and VM750L milling machines, commissioning of the CNC Doosan VM750L milling machine is now complete. The Doosan SMX3100 mill-turn is being installed and due to be fully commissioned mid-November.

These will provide DRB with additional capabilities in the complexity of machined components. This is to support the challenges and growing demands from the industries we support, in continually developing production systems and components to improve operational efficiencies, reduce manual intervention, production downtime and increase component life.

Providing high-tech machining capabilities

The investment of the CNC Doosan VM 750L replaces existing aged machinery. This places DRB in a much more efficient, safe and effective operating position. The 3 axis (with an additional, after market 4th axis) CNC milling machine, referred to as a multi-axis, will increase production efficiency, by providing high-speed manufacturing and increased production accuracy.

Breakages and repairs, with our previous machines was increasing in frequency and becoming an on-going issue. With our growing production and expanding project complexities, this was unacceptable for DRB’s growth and supporting our customers. The VM 750L enable us to work to greater accuracy and reduce downtime and will be an excellent addition to DRB’s capabilities.

Placing DRB Group at the forefront of machining technology

The CNC Doosan SMX 3100 multi-tasking functions of both mill and turn, will grow the complexities of engineering solutions that DRB Group can offer. Having the ability of machining in both the vertical and horizontal axis provides more integral and complex engineering components to be produced. This offers high-speed manufacturing whilst increasing efficiencies and accuracy.

To streamline and automate the manufacturing process, we have also invested in a robot module for the SMX 3100 machine. This will reduce labour time, increase efficiency and improved production scheduling.

Jack said “It is superb to see DRB Group’s vision and commitment to growth, which in the current climate is not always an easy task. They have continued to build their competitive edge and pro-actively moved forward, understanding and anticipating their customers and other industry sector challenges and requirements. With the investments in machinery along with their ongoing commitment to develop the skills needed through their apprenticeship and on-going staff training they are an excellent example of a forward-thinking business. I wish them on-going success and look forward to returning soon.”

DRB Group work to keep production lines running effectively and efficiently.

The investment of these new machines will further progress DRB Group as a leading precision engineering operation, keeping DRB Group at the forefront of machining technology with the ability to support our customers with greater flexibility.

Matt Bennett – CEO “It was a pleasure to have Jack Sargeant visit DRB Group and showcase the investment plan that we are forging ahead with. Our state-of-the-art CNC machining capabilities sets us apart as a leading manufacturer of engineering components. Servicing industries including rail, food and beverage and pharmaceutical, our on-going machinery investments enables us to deliver on more complex engineering components and turnkey projects, to support our customers' needs today and in the future.”

We have a wealth of in-house engineering expertise that enables us to work with our customers, to understand their operational issues, challenges and objectives. Having our own in-house engineering design team and production engineers enables us to manage turnkey projects from concept through to practical engineered solutions. We strive to continually improve and develop production operations to provide cost savings and reduce production downtime and increase efficiencies.

To find out more, about the capabilities of DRB Group contact us now or visit us to see our production capabilities for yourself.

Telephone: +44 (0) 1244 280 280

Email: enquiries@drbgroup.co.uk

Website: www.drbgroup.co.uk

LinkedIn: linkedin.com/company/drb-group-engineering

Published: 6th December 2022

Rachel Wormald, Managing Director at YPS Valves Ltd and Elizabeth Waterman, ...

Are you looking for industry-leading, brand independent valve and actuator ...

As can be seen from the photograph, clearly the resident birds at Bartlett ...

Howco Group has unveiled its latest £1million investment, with the ...

In 2024, Allvalves is poised for an exciting year of growth and expansion, ...

GMM Pfaudler Engineered Plastics & Gaskets are delighted to bring the ...

In the ever-evolving valve industry, GMM Pfaudler stands out for its ...

SAMSON Controls Ltd – part of the SAMSON group - a renowned leader in ...