Transient Response of Swing Check Valve Due to Flow Induced Pulsations

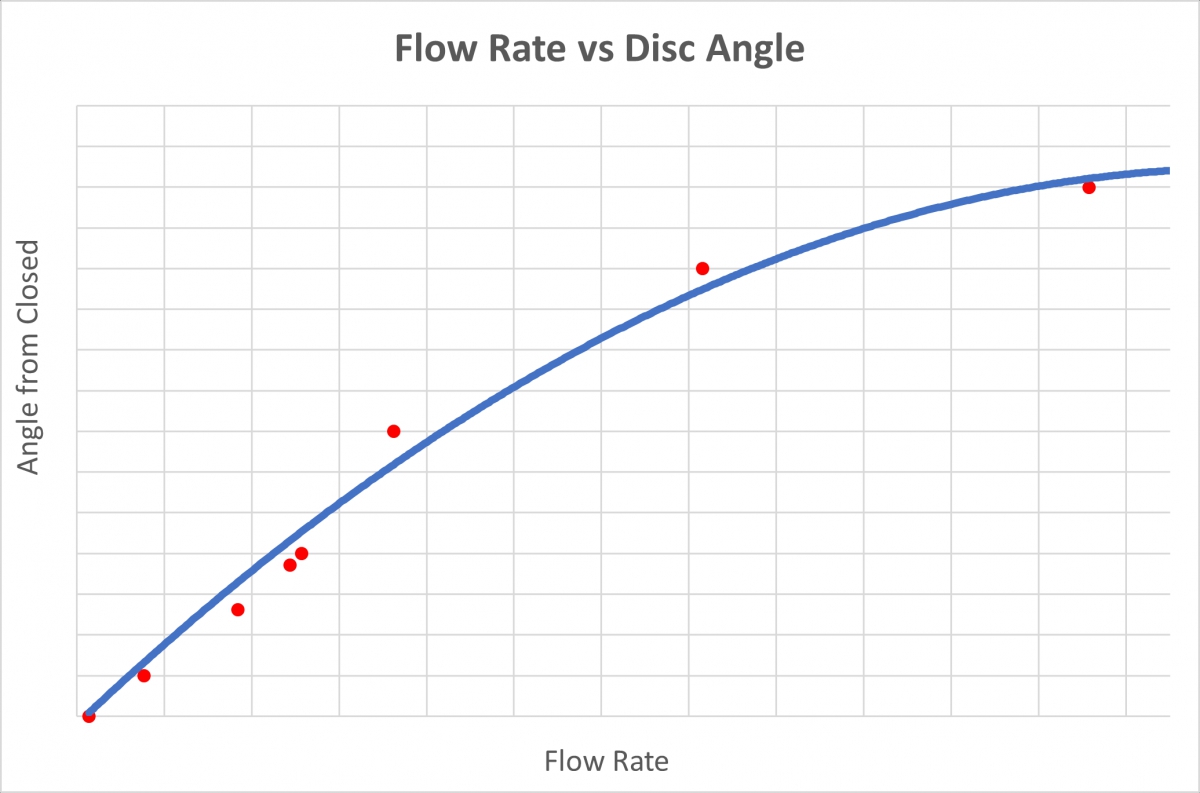

Relationship between disc angle and flow rate

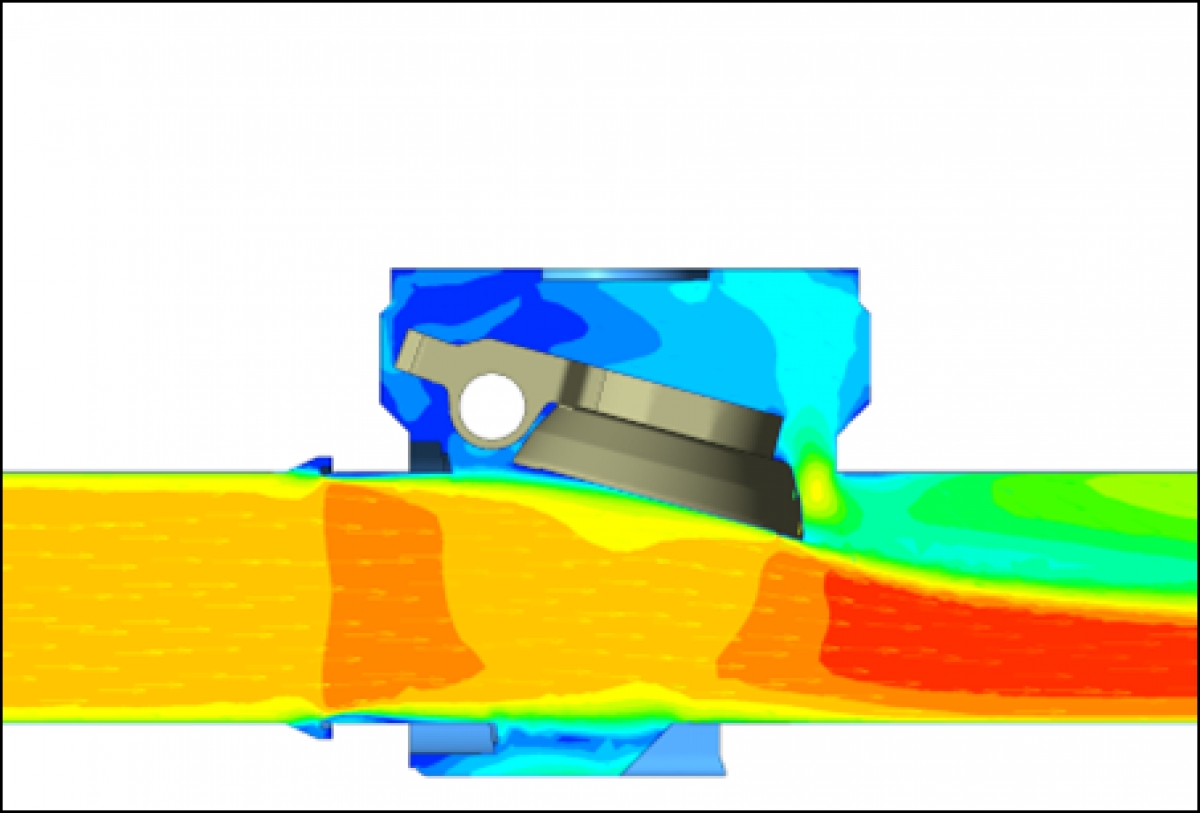

Velocity contours and vectors

PDL Engineering Group are experts in applying advanced engineering software to solve complex technical problems on valve and actuator projects.

Our analysts supported an internationally renowned supplier of high-pressure valves who were developing a subsea non-return valve, which would be subject to a range of operating conditions. The client required design validation to progress through a legislative approval process.

The team completed an investigation into the Fluid Induced Pulsation (FLIP) effect which often occurs in flexible pipes with a corrugated profile on the inner layer, as this profile can cause a build-up of vortex shedding which leads to flow induced pulsations. FLIP can cause excessive oscillatory motions and forces in valves, resulting in a potential early onset of failure. Our analysts also explored the ‘fluttering’ of the valve disc, low flow chattering and an understanding of disc position as a function of flow rate. Hand calculations were carried out for a range of discrete disc angles to determine the torque acting to close the valve, due to disc mass. A Computational Fluid Dynamics (CFD) model was created and parameterised by disc angle to run a separate case for each position: the disc opening position as a function of mass flow rate; the disc oscillatory flutter due to a constant flow; the disc response due to FLIP; and the susceptibility to low flow chattering.

A detailed flutter study was undertaken using a time-dependent transient analysis (see technical spotlight). FLIP was investigated by taking this investigation a step further and applying a sinusoidal pressure profile. The frequency and amplitude of the FLIP were defined and the effects on disc flutter were determined, as well as average forces acting on the disc. The response was inferred from the flutter and FLIP responses and the risk of chattering was identified and summarised in the technical report.

Parametric modelling and analysis significantly reduced the time and costs compared to physical testing and also provided an understanding of fluid flow patterns across a wide range of variables that could not be gained by physical measurement.

To find out more about PDL’s proven track record with clients who rely on them to understand, validate and optimise their valves and actuators visit the PDL website https://pdl-group.com or connect on LinkedIn https://www.linkedin.com/company/pdl-solutions-europe-ltd.

Tel: + 44 (0) 1 434 609 473

Email: solutions@pdl-group.com

Website: www.pdl-group.com

| Telephone: | 00 44 1434 609473 |

| Email: | solutions@pdl-group.com |

| Website: | www.pdl-group.com |

| More information on the PDL Solutions (Europe) Ltd BVAA Member Directory Page |

Search related valve / actuator articles: PDL Solutions (Europe) LtdIssue 89CFD & FEA