BEL Valves - Going in deep

by Chris Williamson, Director of Product Development

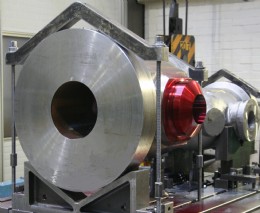

BEL 15,000 psi, 5 1/8 inch valve following successful completion of ultra-deep water tests

Ultra-deep water valve during dye penetrant inspection.

Certainly one of the major drivers is the fact that offshore production in the world’s mature basins has declined and therefore attention has been increasingly focussed on the deep water ‘heavy weight’ regions of Brazil, West Africa and the Gulf of Mexico. Other significant discoveries are also being seen in South East Asia, Australasia the Mediterranean as well as the west of Shetland – a focus that hasn’t gone unnoticed at this years’ Offshore Europe which for the first time will have a dedicated ‘Deep water zone’.

Oil price is, of course another factor driving the momentum for these developments. With a steady rise in oil price since 2000, marginal fields, longer tie backs and deep water developments have become far more attractive propositions.

A third influencing factor is the development of ever advancing technological capabilities and BEL Valves Ltd has positioned itself very much at the forefront of this technology in the high pressure, ultra-deep water range of the market.

So what are BEL Valves doing to deliver solutions in this arena?

Well you can’t fail to have noticed the front cover shot. BEL Valves are leading the way in delivering ultra-deep water, high pressure valves to some of the largest developments in the Gulf of Mexico with the valve pictured having just successfully completed tests at a simulated seawater depth of 10,000 feet (3048m). The qualification valve has already passed its set of performance tests and now has certification to the latest edition of API 6A PR2 and API 17D (ISO 10423 & ISO 13628 respectively).

With all new developments like these there must be a robust set of qualification tests to prove the technology. Any organisation wanting to drive innovation in this high integrity arena has to be prepared to carry out these comprehensive qualification tests, and will often be breaking new ground as pressures get higher and the water gets deeper.

And with these deeper waters comes an increased focus on reliability. The Oil and Gas Industry’s reliability requirements have always been rigorous but now when dealing with deeper water equipment, which is inaccessible for repair, this focus is critical.

BEL Valves design solutions have been born from incremental developments in deep water, tried and tested over a number of years. The confidence that this brings to BEL Valves’ customers cannot be overrated especially when considering reliability and longevity. At such depths if something goes wrong the field may stop producing for some time, so operators will choose suppliers whose products have a long and reliable pedigree at depth and proven reliability data to back that up.

Having secured orders to deliver ultra-deep water, high pressure valves, BEL’s hard work and commitment has paid off, and it seems that this is just the beginning. The ultra-deep water developments opening up across the globe offer significant opportunities, with predicted global capital expenditure on deep water projects forecast at $167 bn up to 2015.

BEL Valves will be exhibiting at Offshore Europe in September where you will be able to see some of the developments that have been made and learn more about the qualification tests required to deliver reliability at these depths and pressures.

BEL Valves

Tel: +44 (0)191 265 9091

Website: www.belvalves.co.uk

| Telephone: | 0191 265 9091 |

| Email: | enquiry@belvalves.com |

| Website: | www.belvalves.com |

| More information on the BEL Valves BVAA Member Directory Page |

Search related valve / actuator articles: BEL ValvesIssue 18Valves