Generic Review of Valve Issues Facing The End User Today

General valve issue data

The data for issues experienced during plant operation is summarized in Slide 1. Typically somewhere between 1% to 15% of valves generated issues, with no issues between 85% & 99%. This is a broad base data which covers specific project valves to regular maintenance valves. I know all the readers would put themselves at the 1% issue level but I have to give some push back here as these clients are limited. At a recent conference in the USA there is a lobby of End Users that believe that the situation is far worse than suggested.

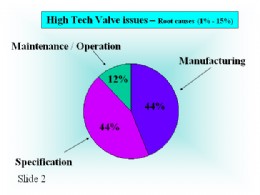

High Tech Valve issues – operations versus manufacturing

Slide 2 shows further details for “High Tech Valve” issue. Here we begin to see some interesting data. 12% of the valve issues can be attributed to poor / lack of maintenance or incorrect operational procedures. 44% can be allocated to manufacturing issues with the remaining 44% to incorrect specifications.

Now let’s just think about that data. 56% of the issues can be directly linked back to the End User! Only 44% of the issues are linked to the manufacturer.

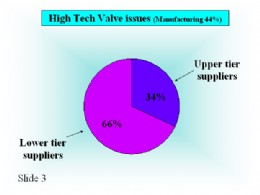

High Tech Valve Issues – Upper Tier versus Lower Tier manufacturers

Slide 3 shows of the 44% of manufacture issues 34% can be attributed to “Upper Tier” manufacturers and the remaining 66% to “Lower Tier” manufacturers.

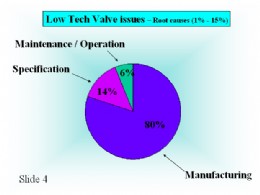

Low Tech Valve issues – operations versus manufacturing

Slide 4 shows further details for “Low Tech Valve” issue. 6% of the valve issues can be attributed to poor / lack of maintenance or incorrect operational procedures. 80% can be allocated to manufacturing issues with the remaining 14% to incorrect specifications.

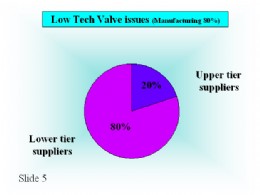

Low Tech Valve Issues – Upper Tier versus Lower Tier manufacturers

Slide 5 shows of the 80% of manufacture issues 20% can be attributed to “Upper Tier” manufacturers and the remaining 80% to “Lower Tier” manufacturers.

Comparison of the Low Tech Valve issues versus High Tech issues shows obvious trends. The influence of the End User on the issues is lower but surprisingly still present. Also the Lower Tier manufacturers are more evident which reflects market trends.

Failure examples – End Users fault???? – Manufacturer fault???? I had recent experience of a high pressure ball valve explosive decompression (“ED”), failure due to incorrect specification. The full process conditions had not been specified correctly.

In another example a bellow seal valve bellows failed. The actual cyclic conditions were assumed rather than being checked.

Again a ball valve seat leaked due to incorrect seat materials being specified for the operating temperature.

A Double Block and Bleed valve failed due to incorrect internal design and manufacturing tolerances. The investigation revealed that the manufacture had been sub-contracted and poor quality control was evident.

An actuated valve failed to operate correctly. It was first thought that the error was under design of the actuator but the cause was due to poor valve stem clearance.

Needless to say many issues consistently cross my desk. Issues with casting leakages and weld repairs for example.

Generic Issues facing End Users in 2011

Please see below generic issues facing End Users in 2011. Each End User is tackling them in various ways. Some are reactive while some are proactive.

In conclusion valve issues are still evident in the industry today and I observe that as End Users continue to seek cheaper low tier suppliers the overall situation will not change in the immediate future. To the contrary it may take some time.

Barrie Kirkman

Tel: +44 (0) 7791 497111

Email: barriekirkman@ntlworld.com

| Telephone: | 01295 221270 |

| Email: | enquiry@bvaa.org.uk |

| Website: | www.bvaa.org.uk |

| More information on the British Valve and Actuator Association BVAA Member Directory Page |

Search related valve / actuator articles: British Valve and Actuator AssociationIssue 18Master Class