BEL Valves

‘One Stop Shop’ suppliers take pain out of specifying and certifying HIPPS

Because of the increase in arduous applications of this type, and the heightened focus on safety in the oil and gas industry, the spotlight has been thrown firmly on HIPPS, with valve manufacturers and systems integrators experiencing an increased demand for this product; HIPPS are specified when pressure relief devices are impractical and there are environmental constraints. But what exactly is a HIPPS, and what should operators and installers have at the forefront of their minds when purchasing a HIPPS solution?

A HIPPS (High Integrity Pipeline Protection System) is essentially an independently instrumented protective device to protect downstream applications, offering the ultimate in system protection. For example if you have a high pressure wellhead, and a lower pressure export link, you need to ensure there is a mechanism in place to protect equipment, personnel and the environment in the event of over pressurisation. There are other options, such as pressure relief valves, bursting disks, or a combination of the two, which work well in particular situations. However these options do have an environmental impact, as they have to relieve the overpressure somewhere. When there is an overpressure problem, the safest thing to do is to shut down the application altogether, and that is what the HIPPS does.

Ultimately the decision to install a HIPPS will depend on the assessment and documentation of the HIPPS’ ability to mitigate risk versus other safety devices, which can be a complex and daunting task. However there are a number of steps you can make to take the pain and risk out of the process. The first is to find a supplier who can offer a ‘One Stop Shop’ HIPPS solution, including all elements from valves and actuators to electronics, and an established track record. BEL Valves and Hima-Sella have recently teamed up to offer such a solution, and between them have more than seventy years experience in the oil and gas industry.

Not only will this save you time in sourcing the final solution, it will also ensure you have access to upfront expertise in designing the solution to meet your stringent and specific requirements, as well as help with installation. A HIPPS system normally requires a Safety Integrity Level (SIL) of 3, and a one-stop-shop HIPPS solution supplier can provide you with a HIPPS which is warranted and certified, importantly for your particular application as for each situation the calculations around risk and probability will be unique. The supplier should also be working closely with a third party safety expert in producing the SIL and other required certifications such as IEC 61508.

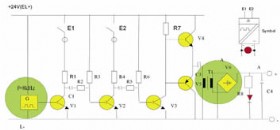

HIMA Planer 4 Logic Solver

Because the valves within a HIPPS solution are small in number and highly specialised, the valve manufacturer should produce low volume, premium bespoke valves for safety critical applications where safety cannot be compromised as their core business, and where the valves have been rigorously tested both in the lab and in service. Importantly the valves need to be fast closing, as if there a sudden surge of overpressure the valve will need to contain the system very quickly. This ability to close rapidly is part of the SIL3 assessment. They may also need to be ‘piggable’, to allow for pipeline cleaning or inspection, and metal-seated Through Conduit Gate and Ball valves, such as those manufactured by BEL Valves, are full port valves which offer this facility.

Finally the HIPPS will need to be monitored once installed, to ensure continued high performance. And since it is now possible to monitor a HIPPS remotely, this service can be undertaken by the HIPPS supplier, acting as your ‘monitoring agent’.... a true One-Stop-Shop HIPPS service. To find out more about the one-stop-shop HIPPS solution contact either BEL Valves (+44 191 204 3738; www.belvalves.co.uk) or Hima-Sella (+44 161 429 4500; www.hima-sella.co.uk).

| Telephone: | 0191 265 9091 |

| Email: | enquiry@belvalves.com |

| Website: | www.belvalves.com |

| More information on the BEL Valves BVAA Member Directory Page |

Search related valve / actuator articles: BEL ValvesIssue 8Safety Valves