GEMÜ Valves in UHT Dairy Products Test Plant

GEMÜ is a global market leader in providing solutions for sterile applications in the pharmaceuticals, foodstuffs and biotechnology industries. To extend the shelf life of dairy products, processes such as fermentation, pasteurization, homogenization, mixing and filling are used and contamination must be avoided. Creating an UHT-ESL (Ultra High Temperature – Extended Shelf Life) testing plant with minimal process deadleg was one of the primary goals and together with plant engineers, GEMÜ developed and integrated the latest valve designs and components and selected the most suitable valves for the processes. GEMÜ stainless steel multi-port valve blocks are used in addition to Globe, Ball and Aseptic Diaphragm valves.

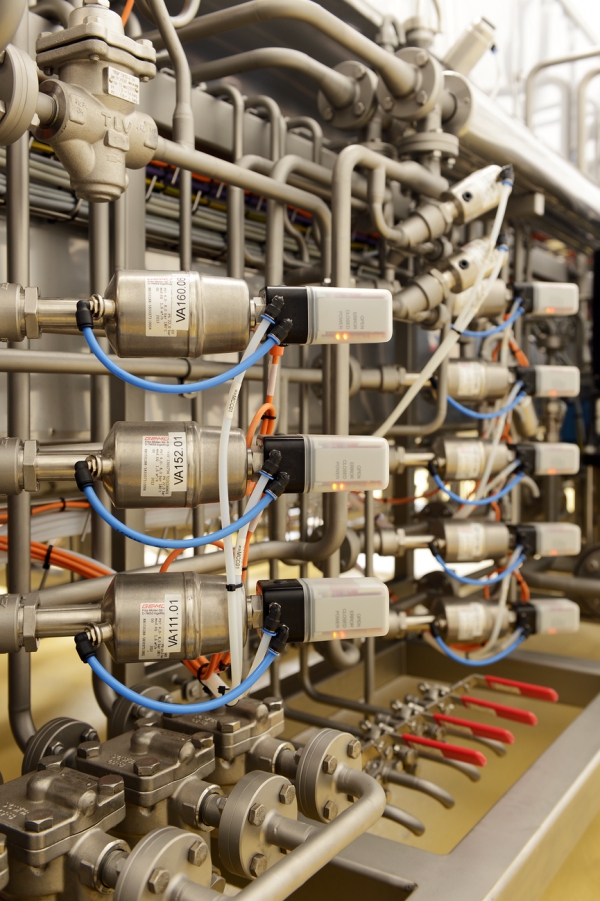

GEMÜ multi-port valve blocks significantly reduce space requirements which enables an extremely compact plant whilst still offering excellent access for servicing work thanks to its modular design. The design also focused on the CIP and SIP capabilities that would allow for cleaning and sterilizing processes without significant disassembly of the process.

UHT plant

The plant thermally treats the milk and highly viscous products such as yoghurt or puddings using different processes. It can process batches ranging from 10 to 4000L. Heating of the product up to 150°C is carried out indirectly, with the provision of steam infusion heating. Heat holding times of up to ten minutes can be achieved for all usual temperature levels. The unavoidable cooling of product during extended heat holding periods is counteracted by clever positioning of the water heaters in the holding sections and appropriate insulation.

GEMÜ products

GEMÜ Diaphragm valves (650 BioStar and 618), designed for optimized draining, are used in the plant in addition to GEMÜ 711 Ball valves and GEMÜ 550 Angle Seat Globe valves with 1434 digital positioners. This ensures that all high points are vented and all low points are drained during steam sterilization of the aseptic tank coupling points. The EHEDG-certified seal system of the GEMÜ diaphragm valves prevents additional deadlegs – a contamination risk.

The customized GEMÜ multi-port valve blocks allow multiple valves and piping/fittings to be combined into a single compact unit. This reduces the number of welds, speeds up assembly and improves plant reliability through the avoidance of possible leakage/contamination points. This range of design-specific measures have thus allowed the best possible hygiene concept to be achieved on this new plant.

Contact:

10 Olympic Way, Warrington, Cheshire, UK, WA2 0YL

01925 824044 | enquiries@gemu.co.uk | www.gemu.co.uk

Published: 30th November 2020

Rachel Wormald, Managing Director at YPS Valves Ltd and Elizabeth Waterman, ...

Are you looking for industry-leading, brand independent valve and actuator ...

As can be seen from the photograph, clearly the resident birds at Bartlett ...

Howco Group has unveiled its latest £1million investment, with the ...

In 2024, Allvalves is poised for an exciting year of growth and expansion, ...

GMM Pfaudler Engineered Plastics & Gaskets are delighted to bring the ...

In the ever-evolving valve industry, GMM Pfaudler stands out for its ...

SAMSON Controls Ltd – part of the SAMSON group - a renowned leader in ...