DMI Young & Cunningham: Project News

In today’s ever challenging working environment, the pressure is almost always on to deliver efficiencies in several areas. Ever tougher production targets, emissions targets and demands to reduce fuel and maintenance costs and battling reliability and breakdowns give an unprecedented complexity to site maintenance. Today, we look at how these challenges are met by the industry‘s most experienced leaders.

UNIC Systems, a leading consultant in the thermal energy sector, has chosen the ECOFLOW Venturi Orifice Steam Traps to deliver the optimum performance for their new rotating drum tunnel dryer.

UNIC Systems supply rotating drum tunnel dryers to a major player in the wooden board manufacturing market. Their customers’ specification for a new tunnel dryer was very demanding. To dry between 20 to 30 tonnes of saturated wood shavings per hour, with a final relative humidity of between 0.5 to 1.5%, requiring in excess of 32000 kJ/kg specific heat capacity.

Günter Kirills, Managing Director of UNIC Systems, understands the challenges these requirements pose. “We knew that the only option for the removal of large volumes of condensate were conventional float traps. Due to the rotation of the drum, the action of this type of mechanical steam trap would be completely compromised. We needed an innovative solution”.

YOUNG & CUNNINGHAM are the UK agent for EBE Engineering, who have been supplying Venturi Orifice Steam Traps for over a decade. When approached by UNIC Systems it was clear that a bespoke solution was necessary.

Nigel Egginton Managing Director of EBE Engineering explained, “We had worked with UNIC Systems on previous projects, but the new tunnel dryer required a complete rethink. We knew that the venturi orifice technology would work but we needed an innovative design that could be incorporated into the overall concept.”

Starting with a blank canvas, we set about applying the knowledge gained over many years dealing with industrial end users. The result of this experience produced the revolutionary ECOFLOW Venturi Orifice Steam Trap.

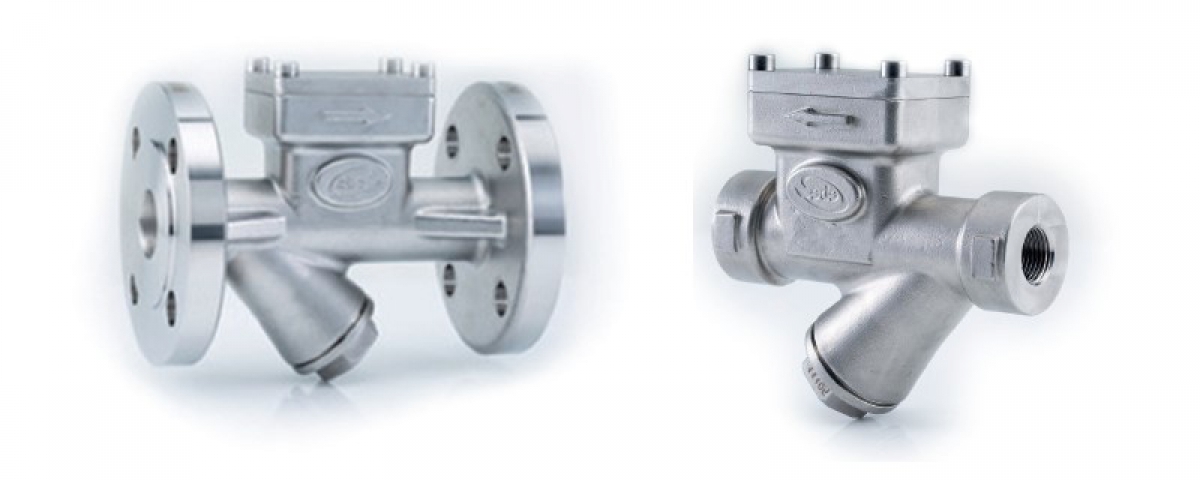

Unlike any other venturi orifice steam trap on the market, the entire trap, including the flanges, was made from a single casting in high grade stainless steel. Applying the latest finite element analysis and fluid flow modelling for the casting, the steam traps integrity is ensured to the highest level.

By incorporating a completely cast housing we were able to develop a modular concept for the steam trap. It enables us to cover a much larger range of capacities and different flanges in the same steam trap body.

The key to success has been the efficient operation of the ECOFLOW venturi orifice trap, as Günter Kikillis explained, “The customer operates older steam heated rotating drum dryers but we have seen a double-digit energy saving with the new design in comparison to these older models. Condensate removal through the new ECOFLOW venturi orifice steam traps has contributed to this impressive improvement. For further projects, the ECOFLOW will be the first choice for future designs”.

Young & Cunningham’s Steve Ingram (General Manager) is clearly impressed with EBE’s capabilities, adding: “The steam traps form a major part of our expanded product range. Along with a new range of butterfly valves and our existing product range, Young & Cunningham now offer the biggest range of valves and flow control related products ever in their history, regardless of application, size or material.”

+44 (0) 191 270 4690 | sales@yandc.co.uk | www.yandc.co.uk

Published: 30th January 2021

Rachel Wormald, Managing Director at YPS Valves Ltd and Elizabeth Waterman, ...

Are you looking for industry-leading, brand independent valve and actuator ...

As can be seen from the photograph, clearly the resident birds at Bartlett ...

Howco Group has unveiled its latest £1million investment, with the ...

In 2024, Allvalves is poised for an exciting year of growth and expansion, ...

GMM Pfaudler Engineered Plastics & Gaskets are delighted to bring the ...

In the ever-evolving valve industry, GMM Pfaudler stands out for its ...

SAMSON Controls Ltd – part of the SAMSON group - a renowned leader in ...