Festo: Time savings, fresh from the oven

A lot of hot air? Not here! Vacuum cooling delivers on its promise and saves Durrer Spezialmaschinen AG a lot of time when it comes to cooling baked goods – and, thanks to Festo, all over the world.

The feeling of flow, of everything running smoothly, is extremely important in a bakery. The day runs to a precise timetable, and begins while most others are still sleeping. Cooling baked goods in particular is a time-intensive process, but one with great potential for optimisation. The flow seen elsewhere in the bakery comes to an abrupt stop here since even conventional cooling methods based on cold air convection need time.

Not so for Durrer Spezialmaschinen AG. The Swiss machine builder uses vacuum cooling with which it can achieve time savings of up to 30%. In vacuum cooling, the pressure of the vacuum is used to lower the evaporation point of the water in the item being cooled.

While water evaporates at 99.6 degrees Celsius at 1 bar, building up a vacuum of 0.006 bar allows the boiling point to be lowered towards freezing temperature.

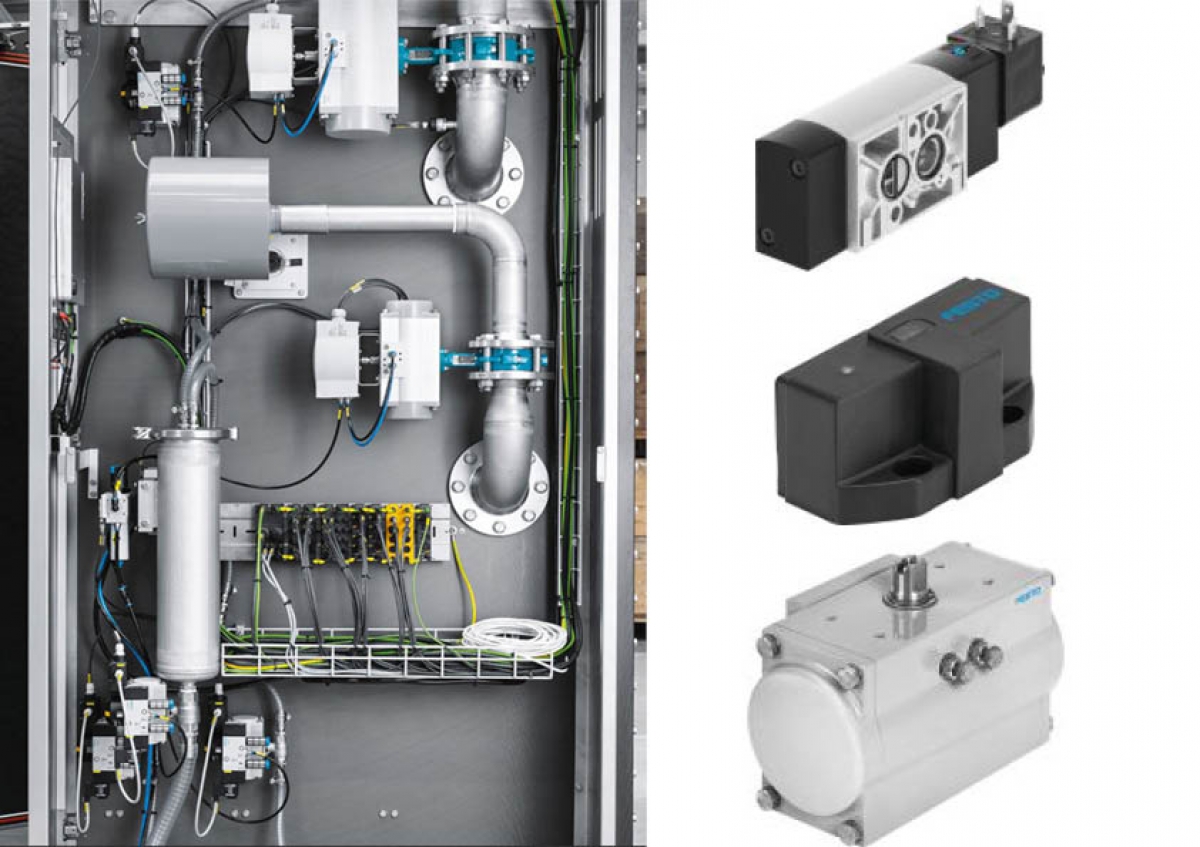

In Durrer’s new VCS Vacuum Cooling Solution, pneumatic process automation from Festo enables a wide range of baked goods to be cooled one after another. This represents an enormous time saving which is reflected in the efficiency of the entire operation.

Apart from the state-of-the-art process automation, however, there is another factor that plays a crucial role for Ludwig Durrer in his partnership with Festo: the worldwide availability. Festo can supply customers of Durrer Spezialmaschinen AG with products and know-how quickly and reliably thanks to its widely distributed global service and support structures – so they can work with vacuum without coming under pressure.

| Tel No: | 0800 626422 |

| Email: | info_gb@festo.com |

| Website: | www.festo.com |

Published: 27th May 2021

Rachel Wormald, Managing Director at YPS Valves Ltd and Elizabeth Waterman, ...

Are you looking for industry-leading, brand independent valve and actuator ...

As can be seen from the photograph, clearly the resident birds at Bartlett ...

Howco Group has unveiled its latest £1million investment, with the ...

In 2024, Allvalves is poised for an exciting year of growth and expansion, ...

GMM Pfaudler Engineered Plastics & Gaskets are delighted to bring the ...

In the ever-evolving valve industry, GMM Pfaudler stands out for its ...

SAMSON Controls Ltd – part of the SAMSON group - a renowned leader in ...