WIKA: How do Diaphragm Seals Work?

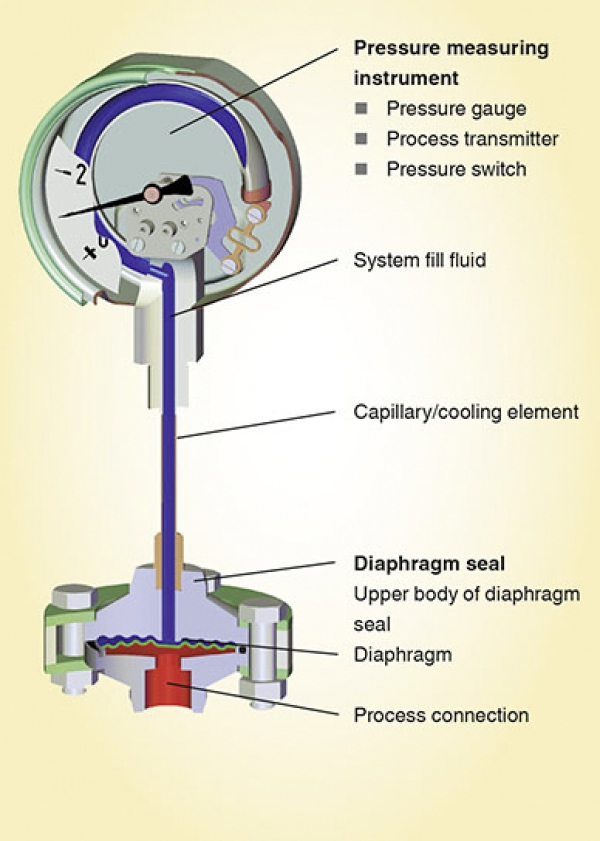

Diaphragm seals, also known as chemical seals or remote seals, are used for pressure measurements when the process medium should not come into contact with the pressurised parts of the measuring instrument. A diaphragm seal has two primary tasks:

- Separation of the measuring instrument from the process medium

- Transfer of the pressure to the measuring instrument

The process side of the seal is isolated by a flexible diaphragm. The internal space between this diaphragm and the pressure measuring instrument is completely filled with a system fill fluid.

The pressure is transmitted from the measured medium by the elastic diaphragm into the fluid and from there to the measuring element, i.e. to the pressure measuring instrument or the transmitter.

In many cases, between the diaphragm seal and pressure measuring instrument, a capillary is connected in order (for example) to eliminate or to minimise temperature effects from the hot fluid to the measuring instrument.

Diaphragm seals are mounted to existing fittings or flanges. Usually the fittings consist of T-pieces which are integrated into a pipeline, or of welding sockets which are welded to a pipeline, the process reactor or a tank.

This diaphragm seal type offers the advantage that the “contact surface” between pressure medium and diaphragm is relatively large, thus ensuring accurate pressure measurement, especially for very low pressures (< 600 mbar).

The fact that they can be easily dismounted, e.g. for cleaning or calibration purposes, is a further advantage.

How do diaphragm seals work? - WIKA blog

Tel: 01737 644 008

Email: info@wika.co.uk

Website: www.wika.co.uk

Published: 15th July 2021

Rachel Wormald, Managing Director at YPS Valves Ltd and Elizabeth Waterman, ...

Are you looking for industry-leading, brand independent valve and actuator ...

As can be seen from the photograph, clearly the resident birds at Bartlett ...

Howco Group has unveiled its latest £1million investment, with the ...

In 2024, Allvalves is poised for an exciting year of growth and expansion, ...

GMM Pfaudler Engineered Plastics & Gaskets are delighted to bring the ...

In the ever-evolving valve industry, GMM Pfaudler stands out for its ...

SAMSON Controls Ltd – part of the SAMSON group - a renowned leader in ...