WIKA: Play it Safe with Double Block and Bleed

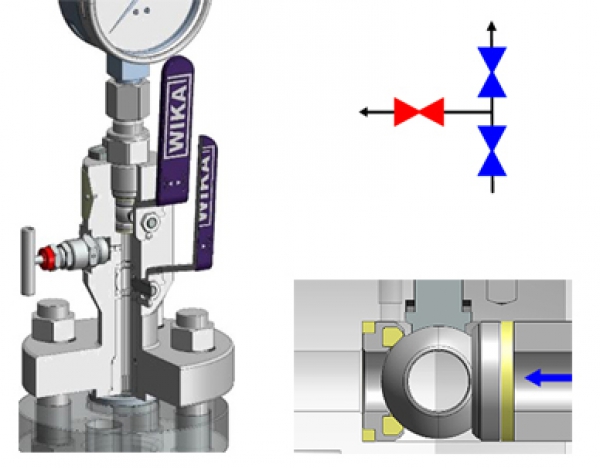

Measuring assembly with ball valve in DBB design: Ball valves from WIKA feature a redundant plastic-metal sealing system. In the event of failure of the “soft” seal (marked in yellow), the pressure pushes the ball seamlessly towards its metal seat.

Measuring assembly with ball valve in DBB design: Ball valves from WIKA feature a redundant plastic-metal sealing system. In the event of failure of the “soft” seal (marked in yellow), the pressure pushes the ball seamlessly towards its metal seat.

What is the safest way to separate a process and the attached pressure measurement technology? The HSG 253 standard must be applied to this question, and it answers unequivocally: by means of an instrumentation valve with double block & bleed (DBB). This configuration for risk minimisation applies especially, but not only, to processes with critical media.

An instrumentation valve with double block & bleed is typically a monoblock. It features two shut-off valves (block) and one vent valve (bleed). If the shut-off valve on the process side no longer closes in the event of a fault, the second shut-off valve prevents uncontrolled media leakage or contamination of the process from outside.

For applications with liquid or viscous media, shut-off valves with a ball valve design are used. For optimised damage prevention, ball valves from WIKA have a combination of plastic and metal sealing: Should the PEEK or PTFE seal fail, the pressure pushes the ball seamlessly towards the metal ring. The redundant system is leak-tested in accordance with BS6755 / ISO 5208 leakage rate A.

Each double block & bleed configuration offers a triple protection:

- For personnel

Fitters and technicians can work at a measuring location with critical media without fear of coming into contact with them. Maintenance or replacement of the measuring instrument is thus possible without danger with a double-blocked valve. - For the environment

Instrumentation valves with double block & bleed prevent the process medium from escaping into the environment. WIKA ball valves and needle valves even prevent fugitive emissions in the appropriate design. These variants are manufactured in accordance with the ISO 15848-1 and VDI 2440 (TA Luft) standards. - For the instruments

Double block & bleed offers the connected measuring instrument optimum protection against potential damage from the process, for example during a cleaning process with aggressive substances. At the same time, this configuration ensures long-lasting and reliable valve operation.

Compact solution instead of self-build

Shut-off solutions as described here could, in principle, be constructed from individual components. However, they would have a correspondingly large dimension, which would affect the stability of the measuring assembly. Because of the numerous parts and connections, there would also be a higher risk of leakage.

Valve solutions in a compact body eliminate the disadvantages mentioned above. For risk-free applications, however, it is advisable to use standard valves (e.g. WIKA models IV10, IV20 and BV). In the case of critical media, monoblocks with double block & bleed configuration are clearly the first choice.

Pratik R. Vishwakarma, Master of Business Engineering, Bachelor of Engineering, Product Management

More info:

Valves and protective devices - Product overview - WIKA

Contact persons - WIKA United Kingdom

| Tel No: | 01737 644 008 |

| Email: | info@wika.co.uk |

| Website: | www.wika.co.uk |

Published: 24th August 2021

Rachel Wormald, Managing Director at YPS Valves Ltd and Elizabeth Waterman, ...

Are you looking for industry-leading, brand independent valve and actuator ...

As can be seen from the photograph, clearly the resident birds at Bartlett ...

Howco Group has unveiled its latest £1million investment, with the ...

In 2024, Allvalves is poised for an exciting year of growth and expansion, ...

GMM Pfaudler Engineered Plastics & Gaskets are delighted to bring the ...

In the ever-evolving valve industry, GMM Pfaudler stands out for its ...

SAMSON Controls Ltd – part of the SAMSON group - a renowned leader in ...