Festo: Application in the Arctic Circle

Drilling for gas in the Arctic Circle – not an easy job. The climatic conditions are extremely harsh and -60°C is not uncommon. Russian energy conglomerate Gazprom was looking for a partner who could supply actuators and controllers that can withstand these extreme temperatures. The explosion-proof pneumatic actuator and control system GBVA from Festo fulfilled the demanding expectations straightaway and has been in use ever since along numerous pipelines in the far north. It has been so successful that many other system operators are now using it too.

Emphasis is placed on durability

The tougher the operating conditions, the stricter you have to be when selecting components for petrochemical systems. Extreme temperatures, explosive materials and distant operating locations place considerable demands on controller reliability for Gazprom. In a nutshell: everything has to be absolutely fail-safe. The next service station is too far away and the terrain is so rough that it would take days, if not weeks, to get replacement parts.

Comprehensive list of requirements

Gazprom’s main requirement for our system was safety: sturdy inside and out, completely temperature resistant, long service life, efficient, saving on resources and manually operable in case of emergency. To ensure that maintenance and service are virtually unnecessary, mechanical damage, caused for example by water hammer, needed to be ruled out. And each valve had to be operated with no more pressure than was really needed for the application. In addition, our solution had to be configurable and adjustable to match the application conditions, such as for example pipeline size. And finally, Gazprom wanted to carry out tests on our valve-actuator unit under realistic conditions.

Festo supplies everything from a single source: project planning, design and implementation. This provides planning security and saves a great deal of time.

Complete solution package from Festo

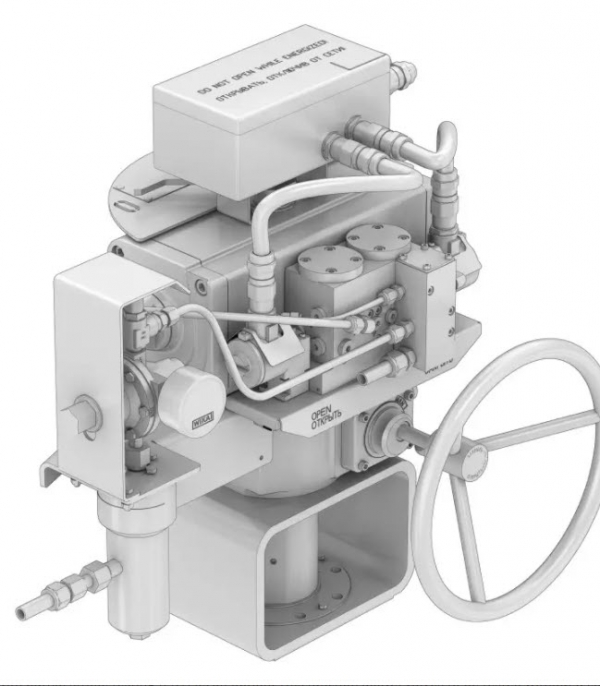

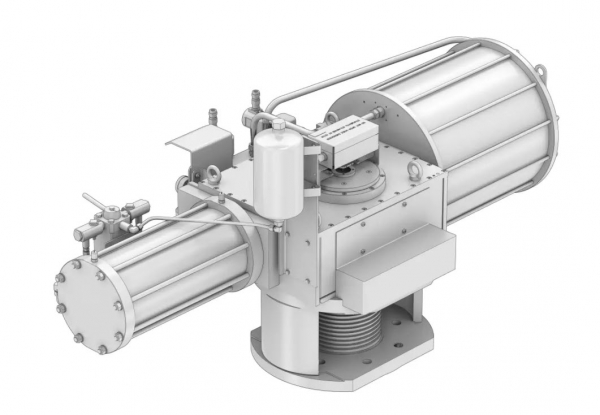

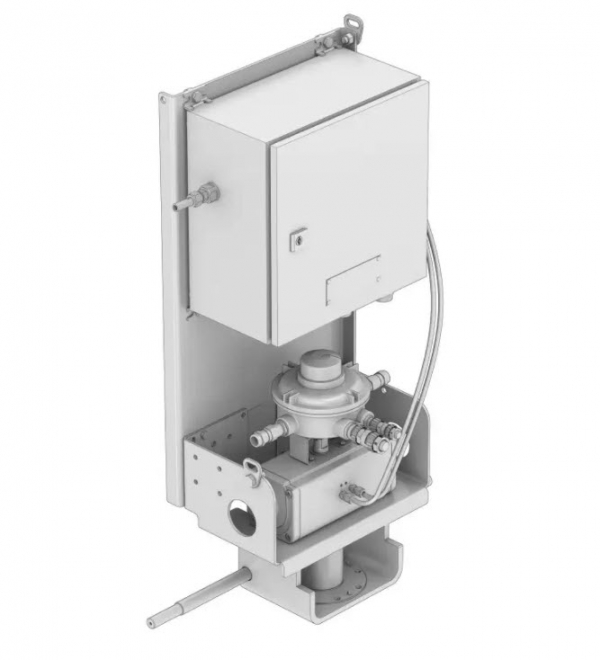

The GBVA (gas ball valve actuator) developed by Festo is a complete valve-actuator solution designed for controlling hazardous media in pipelines and operation at extreme temperatures. All the components are explosion protected (ATEX classification II 2 GD EEx d IIC T5). At the same time, the solution is easy to install, set up, control, maintain and to operate.

Explosion-proof pneumatic actuators

The control principle is based on quarter turn actuators DAPS with an explosion-proof design. Valves VSNZ make it possible to safely switch to the valve actuator in the local control mode. Safety guards prevent inadvertent switching – an important equipment feature for especially dangerous production locations. Pilot valves MGXDH are also used.

Connectors and piping are made of frost-proof stainless steel. The controller is integrated and thus protected. The valve actuator has plenty of torque (up to 120,000 Nm), making it perfect for heavy-duty operation. Controlled opening and closing times ensure gentle motion which is easy on the components and helps to prevent rebound impact and water hammer.

Permissible gas pressure at the system inlet is 413 bar. This is reduced to 2.5-8 bar with a pressure regulator, after which the gas is fed to the actuator chambers. Operation is thus also possible with a minimum pressure of 2.5 bar.

We equipped the GBVA/DAPS with a safety valve. It protects the pneumatic valve actuator from excessive pressure. The valve has a spring whose force counteracts the pressure of the operating equipment. The flow of the operating medium is guided underneath the valve seat.

Extremely broad range of applications

We did everything we could during development of the GBVA/DAPS system so that the number of configurations and versions would be as large as possible. Depending on the size of the piping and the requirements, various cylinder sizes can be used in a solution: actuators DAPS in sizes DN 400 to DN 1200 in single-acting versions (with spring return) or double-acting valve actuators.

Tried, tested and passed

Since the locations where Gazprom would use the system were far apart, we took a great variety of climatic conditions into consideration during development: extremely low temperatures in the Arctic Circle, seismic activity in the Far East and abundant rain and snow in Central European Russia. Independent inspectors have validated the durability of the GBVA by carrying our numerous endurance tests on Gazprom’s test site.

The success story goes on

The pneumatic valve actuators included in the GBVA/DAPS series have been used successfully in the gas industry since 2006. Meanwhile, we have also implemented numerous projects of various sizes and designs. And we don't just work with the gas industry, but also with the petrochemical industry – refineries and terminals – and with operators of oil rigs.

| Tel No: | 0800 626422 |

| Email: | info_gb@festo.com |

| Website: | www.festo.com |

Published: 29th November 2021

Valveuser Magazine Issue 91 is the first of our Special Print Editions for ...

BVAA’s Director Rob Bartlett comments, “In 2024, the BVAA will be ...

Spring Conference & Golf Day, 22-23 May 2024 at Mottram Hall, ...

As 2024 is BVAA’s 85th Anniversary year, I recently had the perfect ...

The international event of reference for industrial valves and flow control ...

As long-term readers of Valveuser will know; Heap & Partners Ltd was ...

WIRRAL manufacturer Heap & Partners has recently celebrated one hundred ...

IMI has announced a record year for orders throughout the hydrogen value chain ...