KSB Ltd: Reviewing the Role of Industrial Diaphragm Valves

Fig.1 The diaphragm is wholly enclosed in the valve chamber within the recess on the cover flange of the valve body.

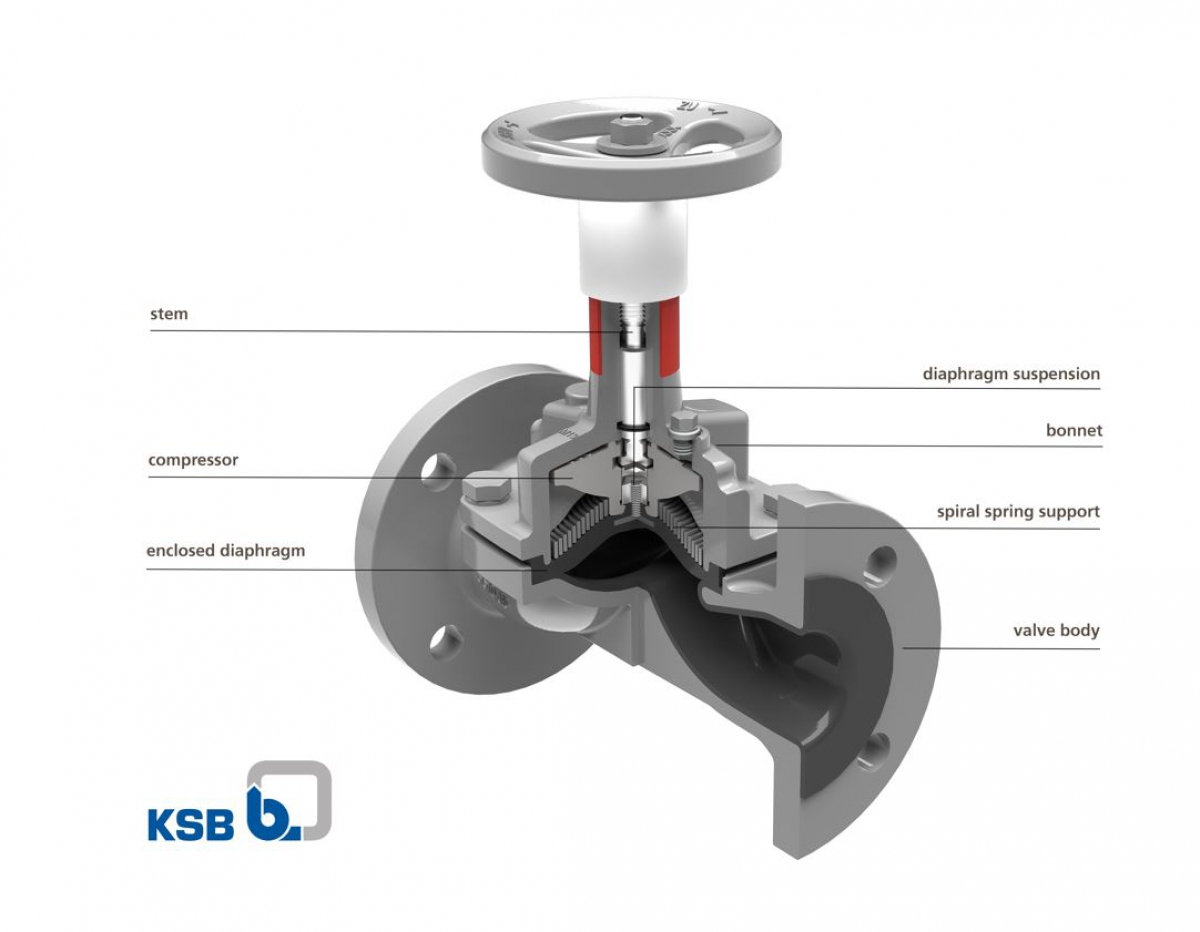

Fig. 2 The SISTO 16/SISTO-20 weir type valves with enclosed diaphragm and spiral spring support.

The transfer of liquids in process operations is an everyday function in many sectors of industry, and therefore demands system designers and operators to give maximum attention to the mechanical elements required for optimum performance. One of those essential elements is the valve. Where the valve performs the role of a throttle device, weir type and straight-through diaphragm valves provide the most appropriate function.

The diaphragm valve is an economic solution for applications where the media being handled is corrosive or toxic, and where high levels of safety are paramount and normally satisfied by alloy metal valves which can be positioned close to pumps, bends, and in both horizontal and vertical pipelines. Furthermore, it has the advantage of eliminating the presence of a dead zone in the fluid chamber, preventing the accumulation of deposits which could cause contamination of the media being handled.

The general appeal of industrial diaphragm valves is that none of the actuating elements in the valve bonnet come into contact with the media at any point in its passage through the valve. Quite simply, there can be no functional impairment or corrosion of the components. Valve operating reliability is, therefore, ensured at all times whether operation is intermittent or just once every few years.

Common to virtually all makes of diaphragm valves is the external body shape and internally the pre-drilled diaphragm, this being sandwiched between the bonnet and the valve body. However, there is an exception to this concept and it comes from KSB. Externally its weir type valves look just like all other diaphragm valves, but internally there is a significant difference: the diaphragm is wholly enclosed in the valve chamber within the recess on the cover flange of the valve body (Fig. 1). Having supplied customers in many countries with this type of diaphragm design and monitoring the results achieved by customers, KSB affirms that its concept of the enclosed diaphragm delivers considerable advantages over other valve types.

KSB diaphragm valves

KSB’s diaphragm valve range encompasses the SISTO-KB straight- through valve and the SISTO 16/SISTO-20 weir type valves with enclosed diaphragm and spiral spring support (Fig. 2). Compliant with all relevant international standards, these valves are all available with a variety of linings, coatings and diaphragms and can be equipped with a range of actuators and accessories.

“KSB’s unique sealing system consists of a chambered diaphragm enclosed in the valve body backed up by a spiral spring support on the back of the diaphragm,” explains Marc Walker, UK Valves Sales Manager. “This arrangement ensures that 100% of the diaphragm surface area is supported from the back at all times and prevents uneven pressure points when the valve is closed or in an intermediary position. On top of this the diaphragm pin is screwed into the compressor and is held through a balanced suspension while remaining manoeuvrable. This avoids specific point loading on the diaphragm during closure so that when pressure is increased the diaphragm cannot tear.”

Sandwich design KSB sealing system

_________________________________________________________________________

Diaphragm is fitted between bonnet Diaphragm is chambered in the valve body

and body in full force closure. with only partial force closure along the

defined sealing area (instead of full force

closure}.

Maximises the durability

Avoids material wear

___________________________________________________________________________

Body-bonnet bolts go through the Bolts are outside the diaphragm.

diaphragm. In the case of leaks the latter become

Risk of medium entering the bolted immediately noticeable.

area unnoticed (thus, related risk of

corrosion).

____________________________________________________________________________

No spiral support Diaphragm is supported by spiral spring

Full pressure on the diaphragm (which Pressure on the diaphragm is evenly

can lead to deformation and faster absorbed by metal spring.

rupture of the diaphragm). Longer durability of the diaphragm due to

reduced strain.

The perfect tightness and fixed position of the diaphragm in its recess provides hermetic sealing to the atmosphere, thereby minimising the potential for media leakage, which is particularly relevant for duties where handling toxic media is involved. The wholly enclosed and supported diaphragm maximises the service life and the pressure limit of the diaphragm.

Due to the unique sealing system of a chambered diaphragm the KSB PIN-16 design enables its valves to accept a maximum pressure of 20bar and temperatures of up to 160°C in certain applications. The lining/coating technology used to protect the valve body from abrasion and corrosion is another critical element in its appeal to a broad spectrum of industrial users. A further advantage of this group of valves is ease of maintenance and replacement. Should it be necessary to replace the diaphragm this can be done without having to dismantle the valve body and without using specialist equipment or measuring tools.

KSB commitment to customers

“KSB operates a vertically integrated production and in-house manufacturing operation incorporating research and development resources,” continues Marc. “This approach enables the company to have complete manufacturing and quality control of all its products. Central to the company’s product development programmes is research into new materials and technologies which results in the introduction of state-of-the-art equipment offering components with the highest of reliability.” says Marc, “For example, use of FEM analysis in the development of diaphragms has allowed the company to speed up the introduction of new concepts, as well as contributing to reliability and performance”.

It is these attributes which have established KSB’s diaphragm valves in fertilizer production, ore processing, chlorine production, raw water or ballast water treatment, gas scrubbing, and food and beverage processing. The company’s substantial investment in the training of personnel means that it has a highly flexible workforce which can be readily deployed between production lines. Enquiries and orders can, therefore, be processed quickly and efficiently to ensure that customers’ requirements and expectations are fulfilled.

KSB’s SISTO 16/SISTO-20 weir type diaphragm valves and the swing check valve RSK/RSKS are available in the UK directly from its operating base in Loughborough. This gives industries in the UK the advantage of having direct access to the manufacturer of these internationally-proven diaphragm valves and to place orders directly with the manufacturer.

|

Tel No: |

01509 231 872 |

|

Email: |

sales@ksb.com |

|

Website: |

|

|

LinkedIn: |

Published: 21st March 2022

Rachel Wormald, Managing Director at YPS Valves Ltd and Elizabeth Waterman, ...

Are you looking for industry-leading, brand independent valve and actuator ...

As can be seen from the photograph, clearly the resident birds at Bartlett ...

Howco Group has unveiled its latest £1million investment, with the ...

In 2024, Allvalves is poised for an exciting year of growth and expansion, ...

GMM Pfaudler Engineered Plastics & Gaskets are delighted to bring the ...

In the ever-evolving valve industry, GMM Pfaudler stands out for its ...

SAMSON Controls Ltd – part of the SAMSON group - a renowned leader in ...