GEMÜ's Solutions for Mixing Electrode Slurries in Li-ion Cell Manufacturing

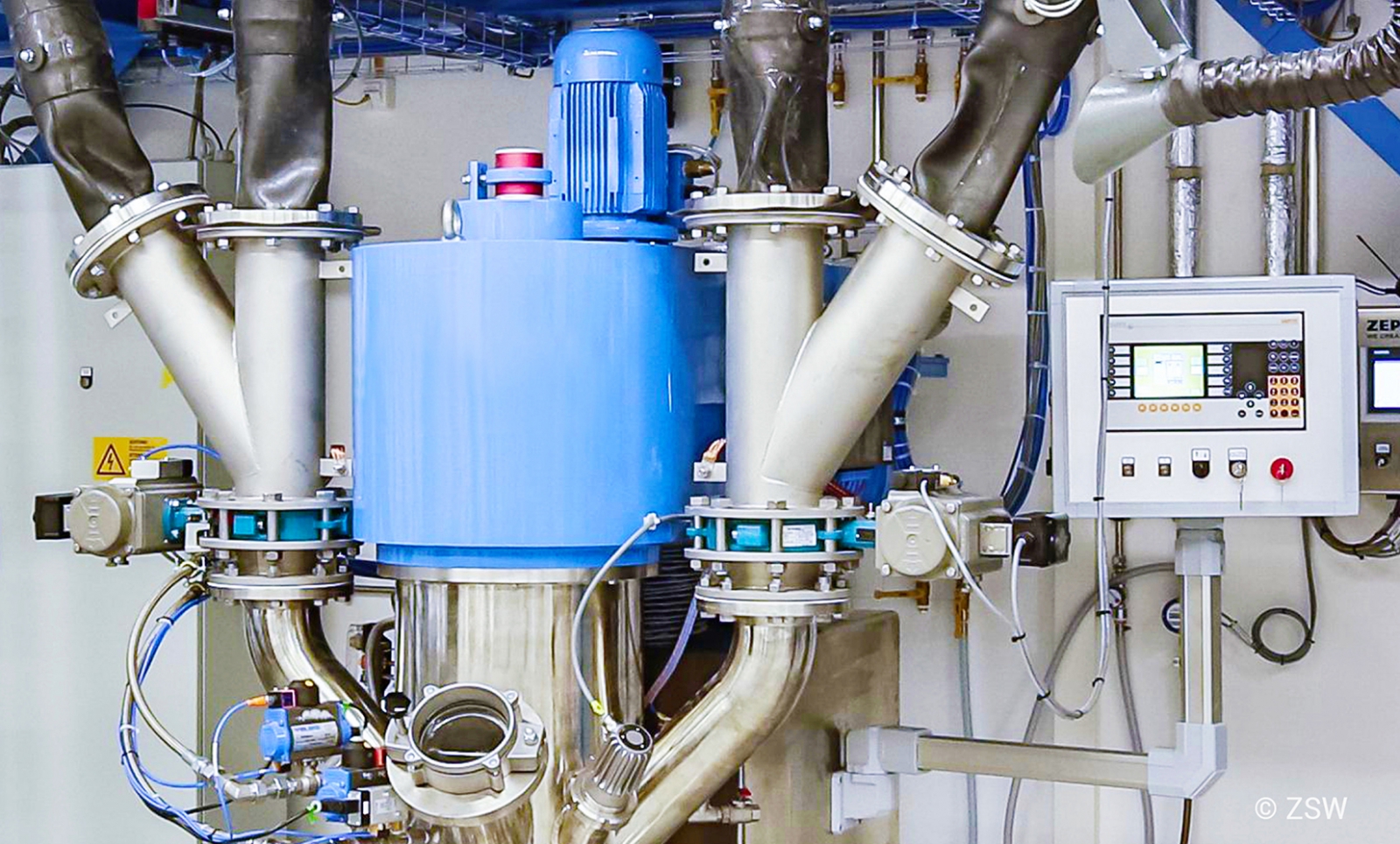

Example of slurry mixing plant

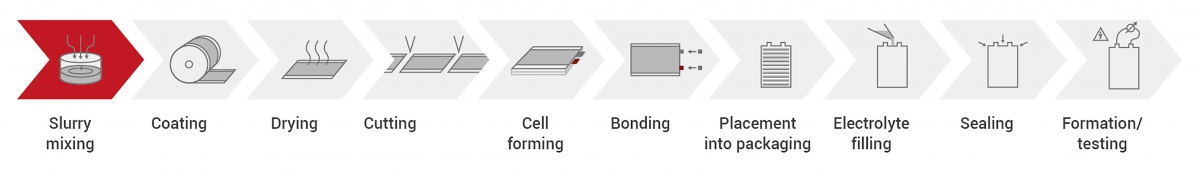

Li-ion cell manufacturing process

GEMÜ capabilities in the area of Li-ion cell manufacturing

As a leading manufacturer of valves, measurement and control systems, GEMÜ has increasingly established itself in high-tech markets as one of the market leaders in the manufacturing of Li-ion battery cells, GEMÜ is working together with its customers to develop solutions for the relevant production steps – from slurry mixing to electrolyte filling.

Slurry mixing in Li-ion cell manufacturing

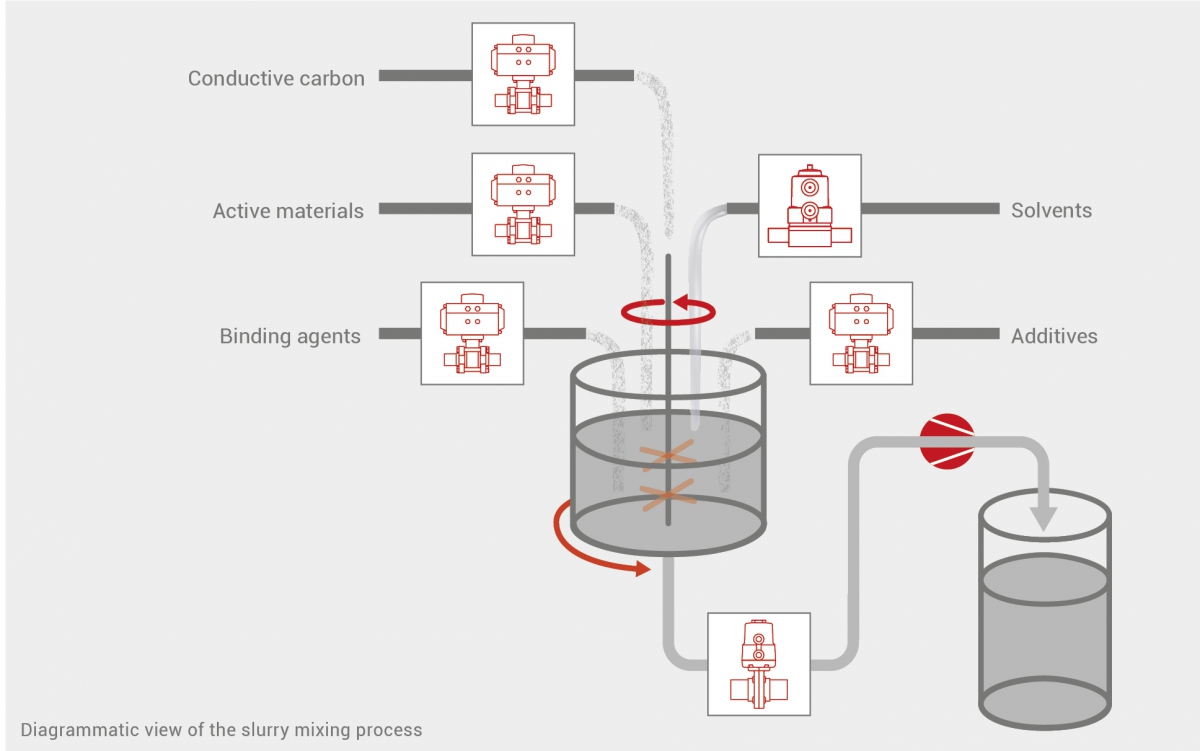

The first step in the manufacturing Li-ion battery cells is mixing the electrode slurry, which is then applied to the electrode foils (anode/cathode) as a layer in the next step. The slurry comprises a mixture of active materials, solvents, binders and additives. When mixing slurry, it is particularly important to feed in the different components in precisely the correct quantities. GEMÜ offers comprehensive valves, measurement and control systems to ensure process reliability in each of the manufacturing steps.

Different mixing procedures

The slurry can be mixed via various procedures. In this application, an individual container is filled and then mixed continuously which is known as a batch-based mixing procedure.

With continuous mixing, this process is automated and makes slurry continuously available to the coating systems. Both mixing procedures require strict specifications on the components used in the process.

Customer benefits

- GEMÜ has an extensive range of valves and accessories perfectly suited for this application.

- Careful and safe media handling of active materials and solvents.

- GEMÜ valve components are designed with minimal dead leg, allow self-draining and therefore are simple to clean and reduces cross contamination.

- ATEX certification allows use in explosion-proof zones.

- High chemical resistance for the stainless-steel components.

Why GEMÜ?

Through continuous innovation, focusing on quality and customer-oriented solutions have made GEMÜ one of today's world leading manufacturers of valves, measurement and control systems.

With decades of expertise and experience, GEMÜ has excellent references in valves and components used in the applications with high purity requirements, such as in areas of (micro-) electronics and semiconductor production right up to battery cell manufacturing.

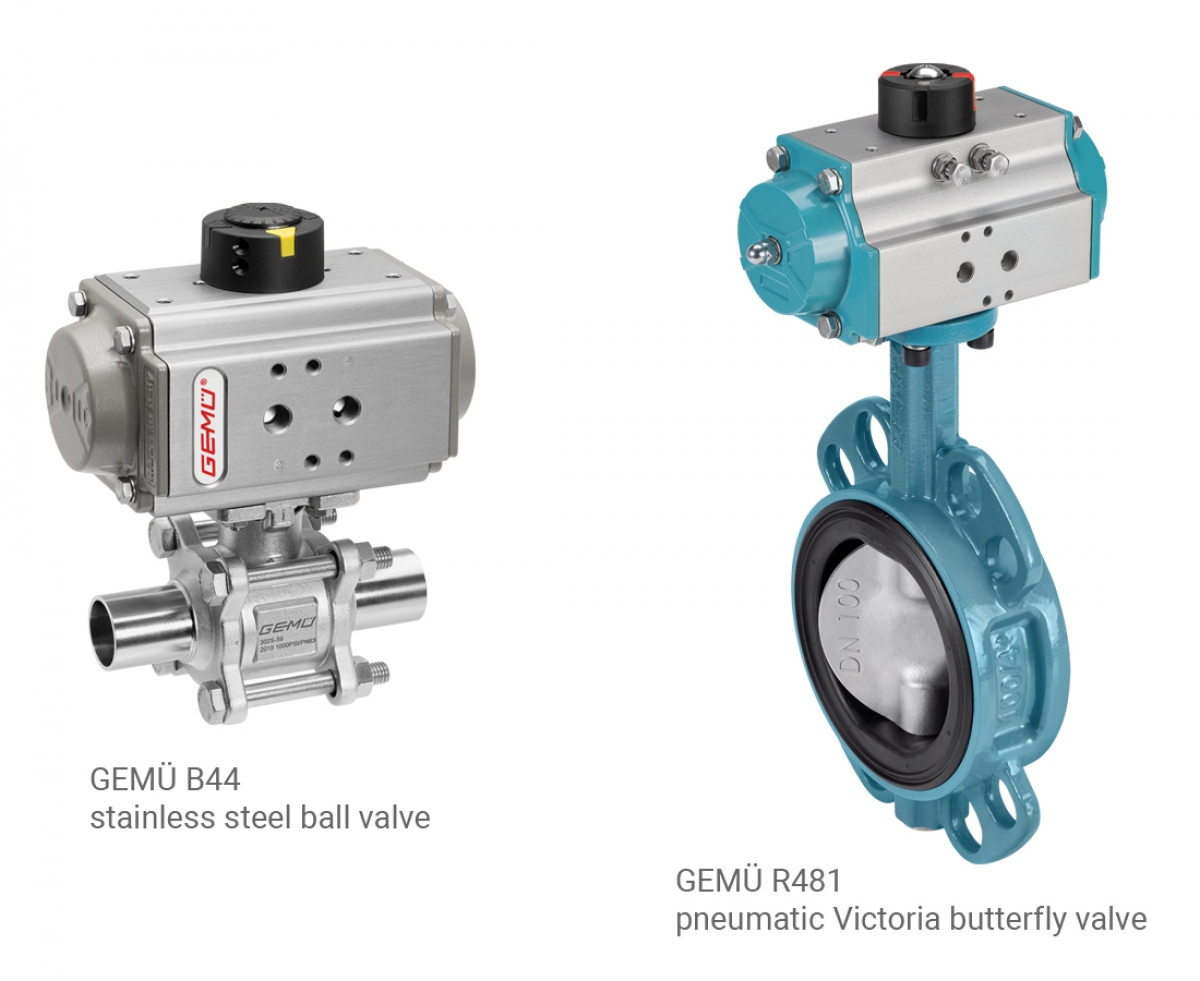

Slurry mixing plants require chemical resistance and precise media handling as basics, together with a compact and modular design and a long service life. GEMÜ Butterfly valves R480 Victoria series and GEMÜ stainless steel ball valves B44, are the most appropriate valves for the requirements needed in this application.

With its extensive product range and dedicated teams, GEMÜ is committed to provide customer-oriented solutions, especially in the area of battery cell manufacturing, where GEMÜ not only acts as an equipment supplier but also as a partner in the development process with the end user or contractor.

For more information, click here.

Check out the video to see how we manufacture our Next Generation of GEMÜ rubber lined Butterfly Valves R480 Victoria series:

|

Tel No: |

01925 824044 |

|

Email: |

|

|

Website: |

|

|

LinkedIn: |

Published: 29th June 2022

Rachel Wormald, Managing Director at YPS Valves Ltd and Elizabeth Waterman, ...

Are you looking for industry-leading, brand independent valve and actuator ...

As can be seen from the photograph, clearly the resident birds at Bartlett ...

Howco Group has unveiled its latest £1million investment, with the ...

In 2024, Allvalves is poised for an exciting year of growth and expansion, ...

GMM Pfaudler Engineered Plastics & Gaskets are delighted to bring the ...

In the ever-evolving valve industry, GMM Pfaudler stands out for its ...

SAMSON Controls Ltd – part of the SAMSON group - a renowned leader in ...