Rapid Gas Decompression in Extreme Environments

By Jean-Luc Matoux, Global Application Engineer for Energy & Materials Handling, DuPont

New oil drilling environments challenge the performance of valve seals. Copyright DuPont

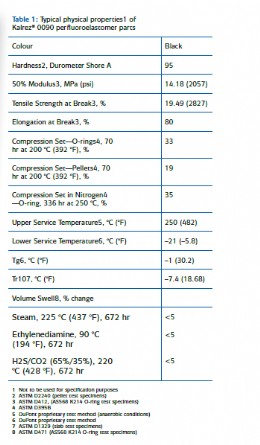

Perfluoroelastomer seals offer the highest temperature and chemical resistance of all elastomers

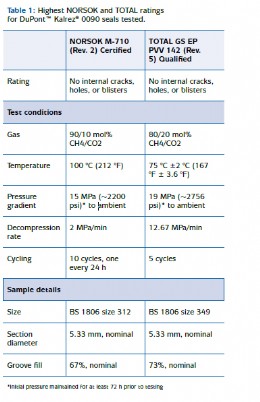

NORSOK M-710/MERL and TOTAL GS EP PVV/CETIM certifications of Kalrez® 0090 RGD resistance

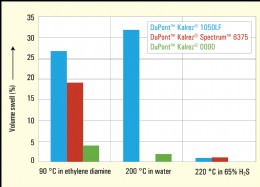

Comparison of chemical resistance of Kalrez® 0090, Kalrez® Spectrum™ 6375 and Kalrez® 1050LF demonstrates outstanding resistance of Kalrez® 0090, particularly to high concentrations of hydrogen sulphide (H2S)

The spectre of shrinking global oil reserves and the search for new, more difficult sources such as deep water and shale is well documented. Many new exploration sites challenge the oil and gas industry with increasing extraction pressures and temperatures, and by the presence of aggressive chemicals such asammonia, carbon dioxide, hydrogen sulphide (sour gas), methane, and steam — exacerbated by the phenomenon of rapid gas decompression (RGD).

Often referred to as HPHT (high pressure/high temperature) environments, these more aggressive drilling conditions pose a new set of problems for suppliers and operators of surface and downhole ball valves, packers, pumps, mechanical seals and drilling tools because they create operating environments beyond the capabilities of many commonly used equipment-sealing elastomers like hydrogenated nitrile rubber (HNBR) and fluoroelastomers (FKM).

Combinations of RGD, HPHT, and harsher chemicals can lead to seal failure, with the associated risks of, costly financial, safety and environmental issues, and ultimately to shut downs.

The benchmark of seal performance

This scenario was one of the reasons why the industry pressed for the establishment of a test standard to qualify non-metallic sealing materials. NORSOK standard M-710, Rev. 2, October 2001, developed by the Norwegian petroleum industry, has been widely adopted internationally as the benchmark of performance for any elastomer seal in critical oil and gas service. NORSOK certification for RGD is essential to qualifying performance of elastomer seals in HPHT and aggressive chemical environments, with the objective of reducing the risk of seal failure. TOTAL general specification GS EP PVV 142, Rev. 5, developed by TOTAL, is also widely accepted as an independent test of elastomer seal resistance to RGD in valve applications.

“0000” is the highest rating in NORSOK certification

In the NORSOK and TOTAL tests for RGD resistance, O-rings are subjected to pressures, temperatures and fluid media in a laboratory autoclave for 72 hours, replicating severe downhole well conditions, and then repeatedly pressurized and depressurized over a further 48 hours. The O-rings are then released from the jig, cut into four sections and examined by microscopy for RGD damage.

The NORSOK rating system determines the degree of internal crack damage to each O-ring cross section on a scale of 0 to 5, with a 0 rating being given to an O-ring section with no internal cracks, holes or blisters of any size, and 5 rating made where cracks go through the cross section, or the seal separates completely into fragments. Ratings from 4 to 5 are not acceptable; 1,2 and 3 are considered acceptable. A 0 rating is the highest rating. A “0000” rating, where each section of an O-ring has no cracks, is considered best and confirmation of superior RGD performance for an elastomer seal in testing conditions.

Kalrez® 0090: Achieving highest rating

Perfluoroelastomer (FFKM) parts offer the highest temperature and chemical resistance of all elastomers, and are at the very top end of seal performance in the most aggressive chemical processing and oil and gas applications.

DuPont has more than 30 years experience serving the oil and gas industry with Kalrez® perfluoroelastomer parts. With oil extraction environments becoming more and more challenging for elastomer seals, DuPont embarked on a new formulation program in 2008 with the primary objective of developing a new compound with enhanced RGD resistance. Due to its fully integrated supply chain, DuPont was able to test hundreds of different formulations — not only using various curing chemistries and fillers but also alternative polymers — leading to the development of DuPont™ Kalrez® 0090 perfluoroelastomer parts. Before launch in 2010, Kalrez® 0090 parts were submitted for rigorous RGD resistance testing in October 2009 by the Materials Engineering Research Laboratory (MERL) in the UK, according to the NORSOK M-710 Rev. 2 standard.

The samples were exposed to a test gas of 90% methane and 10% carbon dioxide at 150 bar and 100°C, and a decompression rate of 20 bar/minute (see Table 1).

The Kalrez® 0090 (K-312 “A”) O-ring samples tested were certified as having attained the best possible NORSOK 0000 rating for rapid gas decompression resistance.

This superior performance was also substantiated in January 2012 by further tests conducted at the Centre Technique des Industries Mécaniques (CETIM) of France, in accordance with the TOTAL GS EP PVV 142, Rev. 5 procedure (see Table 1). CETIM found DuPont™ Kalrez® 0090 O-rings 113,67 x 5.33 mm also fullfill the acceptance criterion of the TOTAL General Specification GS EP EVV 142 Rev. 5. concerning O-rings used in the industrial valve industry.

About Kalrez® 0090 parts

Kalrez® 0090 is the latest in a family of DuPont perfluoroelastomer parts for the oil and gas industry that includes Kalrez® Spectrum™ 6375 and Kalrez® Spectrum ™ 7090.These products provide the optimum balance of chemical, heat and mechanical properties for different chemical and oil and gas sealing applications.

DuPont claim to be the only fully integrated perfluoroelastomer seal manufacturer, having total upstream and downstream expertise of monomer, polymer, compounding and finished product.

Key performance characteristics of Kalrez® 0090 seals:

• Exceptional resistance to rapid gas decompression, certified to highest 0000 rating in NORSOK M-710, Rev. 2 laboratory tests made with Kalrez® 0090 K-312_ “A_ O-rings

• Withstands attack by over 1800 chemicals, and resists ageing in sour fluid, including multi-phase fluids containing high concentrations of hydrogen sulphide

• Retains high levels of elasticity, recovery and extrusion resistance even after long-term exposure to temperatures as high as 250°C and as low as -40°C in high pressure environments.

• Although Kalrez® 0090 parts are a high hardness perfluoroelastomer, it remains elastomeric with low compression set under most aggressive HPHT environments.

Technical information and data sheets on all standard and specialty Kalrez® perfluoroelastomer products are available at www.kalrez.dupont.com

Proven in commercial service

DuPont™ Kalrez® 0090 perfluoroelastomer seals with enhanced RGD-resistant properties are currently in use at several major oil and gas companies, and many leading oil OEMs have qualified Kalrez® 0090 seals for use in surface and down hole valves, data logging drilling tools, packers, completion tools and mechanical seals.

Learn more about Kalrez® and Rapid Gas Decompression, view video online http://www2.dupont.com/Kalrez/en_ US/applications/oil_gas/seals.html

Authorized Distributors of Kalrez®

In the UK, Kalrez® 0090 perfluoroelastomer seals and technical support are available from Authorized distributors of DuPont™ Kalrez® and BVAA member Dichtomatik Ltd, of Derby.

Dichtomatik Ltd

Tel: 01332 524401

www.dichtomatik-kalrez.co.uk

| Telephone: | 01332 524 400 |

| Email: | sales.derby@fst.com |

| Website: | https://on.fst.com |

| More information on the Freudenberg Sealing Technologies Ltd BVAA Member Directory Page |

Search related valve / actuator articles: Freudenberg Sealing Technologies LtdIssue 30Master Class