Cost Reductions Achieved by Valve Condition and Performance Monitoring

Part One: Score Diagnostics Limited’s Portable MIDAS Meter®

In the oil and gas markets, the most significant costs are the initial investment in the design, construction and installation of the process plant, whether that is an offshore oil platform or an onshore refinery. Once producing, the safe, environmentally sound and efficient continuous operation of these processes becomes the focus of the stakeholders. Any break in the production output attracts a potential major loss of income, so we can see how critical the maintenance decisions and activities become in this market.

Given these conditions, it is understood that innovations and technology which help operators avoid unnecessary downtime generate a lot of interest, especially when the adoption costs are low in relative terms, when compared to the potential downtime costs it avoids.

Reliability studies have proven that all mechanical equipment fails over time and when looking at valves, that failure represents major risks to plant operations. These risks include:

• Safety Accidents/Incidents

• Environmental Escapes

• Efficiency/Profit Losses

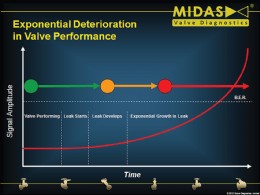

Knowing where your valve is in its performance lifecycle at any given point in time has a high potential value.

Score Group plc has developed a number of valve condition and performance monitoring products and services to address their existing customers’ and the wider market’s needs. We examine the ‘entry level’ Midas meter below, details of permanently installed and fully integrated solutions can be found in part two of this article on page 58:-

An Ultra-Portable and Intrinsically Safe Certified Acoustic Emissions (AE) Valve Condition Monitoring Devic

Quickly, Easily and Non-Invasively Find, Quantify and Trend Through Valve Leaks

The “entry level” product for through-valve loss/leak detection and quantification is the hand-held MIDAS Meter®, which uses an acoustic emissions (AE) sensor to detect the high frequency sound signals emitted by leaks across isolating valves’ seat to seal interfaces. It is a non-invasive inspection technique which requires the operator to place the sensor directly onto the outside surface of the valve body. Once in position, it is possible to see within a few seconds if there is any leakage across the valve seat(s). Using the PDA-based software, the operator can immediately calculate an estimated leak rate, which can of course then be trended over time. This device is ideal for customers looking to carry out maintenance troubleshooting and Risk Based Inspections (RBI) of valve populations.

MIDAS Meter® Case Study:-

After trying 2 alternative and unsuccessful leak detection methods, the customer turned to Score’s MIDAS Meter®. Despite the extremely high background noise in the area of the plant where the valves were located, Midas Meter® was able to conclusively identify the two problematic leaking valves (from 12 suspected) on one train and target them for maintenance.

Having the Midas Meter® as part of the initial plant troubleshooting plans would have saved the customer a great deal of time and effort, leading to significant cost savings, by avoiding a wider scope of unnecessary remedial repair work and plant downtime.

Based on their positive experience with MIDAS Meter®, the customer proceeded to purchase it.

Full details of this and other case studies can be supplied on request.

Score Group plc / Score Diagnostics Limited

Tel: 01779 480 000

Web: www.score-group.com

| Telephone: | 01779 480000 |

| Email: | europeafrica@score-group.com |

| Website: | www.score-group.com |

| More information on the Score BVAA Member Directory Page |

Search related valve / actuator articles: ScoreIssue 34Valve Repair and Service