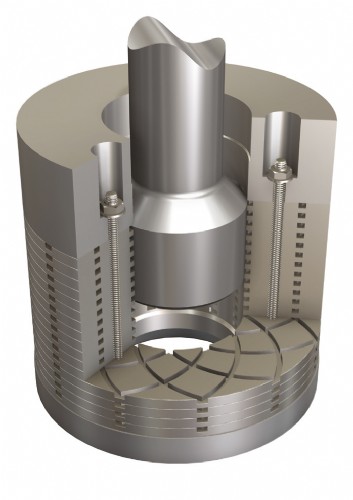

Flowserve Introduces Valtek® DiamondBack Cavitation Elimination Technology

DiamondBack Is the Control Valve Industry's Most Advanced Design for Cavitating Applications

DiamondBack enables control valve users to eliminate high-pressure drop cavitation damage and the associated noise. In addition, the DiamondBack design can be produced in a range of materials, including tungsten carbide, effectively mitigating the effects of erosion. Providing improved reliability and uptime with reduced operating and maintenance costs, DiamondBack also delivers up to 30 percent higher flow than comparable multi-stage valve trim with the same pressure drop. In some applications, this results in a smaller and lighter package than other designs.

DiamondBack cavitation elimination technology is available for installation in all new or existing Valtek Mark Series control valve body sizes.

According to Flowserve Severe Service Products Marketing Manager Bradford Haines, "Combining the proven and preferred Flowserve Valtek Mark Series control valve with DiamondBack severe service trim provides users with maximum cavitation protection. With the purposeful selection of available materials of construction, DiamondBack further offers excellent corrosion resistance. As a result, DiamondBack is uniquely capable of delivering comprehensive protection from both cavitation and erosion damage."

DiamondBack is customizable for the most rigorous application requirements in the oil and gas, chemical processing, power generation, and general industries, and is able to pass slurries and entrained solids to 15 mm (0.5 in) without plugging. It is available in all commonly specified materials, including 300 and 400 Series stainless steels and high-nickel alloys, as well as exotic alloys and tungsten carbide.

Tel: 01444 314 400

Email: ukfcinfo@flowserve.com

Web: www.flowserve.com

| Telephone: | 01444 314400 |

| Email: | ukfcinfo@flowserve.com |

| Website: | www.flowserve.com |

| More information on the Flowserve Flow Control (UK) Ltd BVAA Member Directory Page |

Search related valve / actuator articles: Flowserve Flow Control (UK) LtdIssue 36Control Valves