The Always Reliable DeZurik Plug Valve

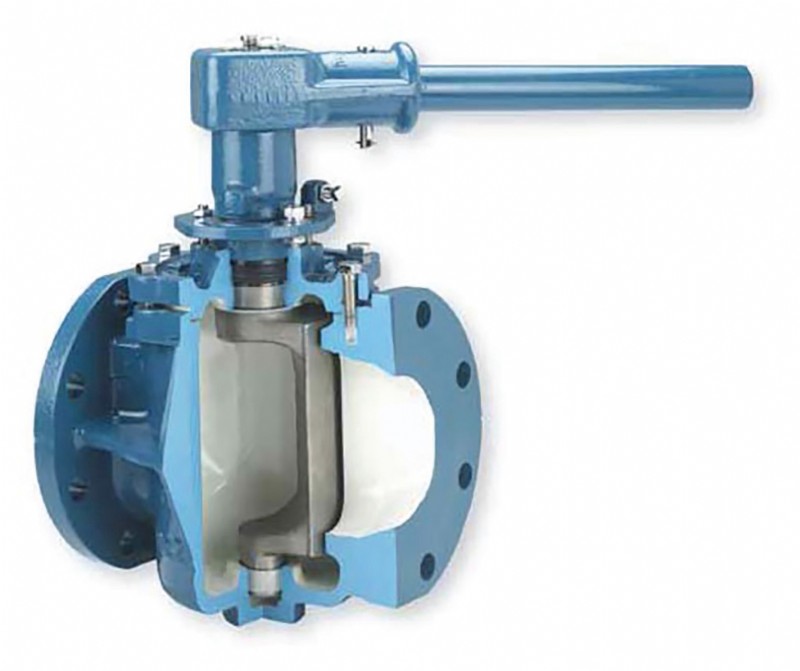

Figure 1.

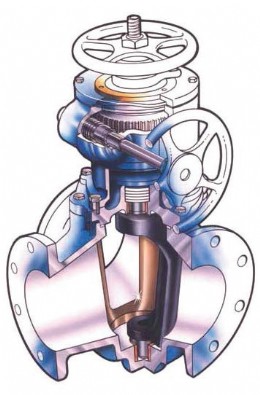

Figure 2.

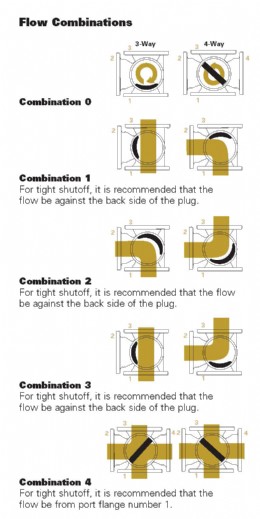

Figure 3.

The plug valve has evolved since the cast iron, resilient-seated plug valve was introduced in 1928 much about it has stayed the same.

One reason today’s DeZurik plug valve has been around so long is that once installed, it remains functional for decades of uninterrupted on-off service, throttling service, and flow diversion. The plug valve is used for applications that require tight sealing with good wear resistance for handling fluids, with some solids such as paper stock and wastewater. Applications include water and wastewater treatment plants, water distribution systems, power and chemical plants, HVAC, paper mills, and mining operations.

DeZuriks PEC plug valve is a rotating motion valve used to stop, start, control, or direct flow. It receives its name from the shape of the internal plug mechanism, which is one of the plug valves’ three basic components; the other two are the body and bonnet/cover. The plug is the only moving member. When turned 90 degrees from the open position, the solid part of that plug blocks the ports and stops fluid flow, or in multi-ported valves, diverts flow from one port to other ports.

The DeZurik PEC Eccentric Plug valve

The eccentric plug valve (Figure 1) derives its name from the fact the plug’s rotational action is eccentric in nature relative to the longitudinal axis of the plug.

This rotational action allows the plug to contact the seat only in the last few degrees of rotation, which eliminates most rotational wear and friction between the seat and the plug. This design also allows the valve sealing to be controlled by the torque applied to the plug. The eccentric action allows the plug to cam into the seat and provides tight shutoff, which reduces wear on the plug and seat. The sealing surfaces may be metallic or elastomer lined.

When the eccentric plug rotates 90 degrees from opened to closed, it moves into a raised eccentric seat. In the open position, the plug, which is segmented, is out of the flow path. Flow is straight through, and flow capacity is high. As the plug closes, it moves toward the seat without contact with the seat or body walls, so no interference or wear occurs. Flow is still straight through, however, making the throttling characteristics of the eccentric plug valve ideal for gas, liquid, and slurry applications. The plug only makes contact with the seat in the closed position. When furnished with a resilient facing, the plug is pressed firmly against the seat in the body and provides a tight seal.

Installation of Eccentric Plug Valves

The correct installation procedure for the eccentric plug valve is determined by the type of materials carried in the pipeline, and the location of the valve in the piping configuration.

In horizontal pipelines the valves should be installed so the plug is horizontal and rotates upward as the valve opens. Flow against the plug face pre-vents solids from packing in the body cavity when shut. When there is no chance of overhead drain-back, the valve should be installed with flow against the face of the plug. Installing the valve so that it is in a horizontal rotational axis keeps the journals free from sediment. The valve also should be installed so that the plug rotates upward 90 degrees to open. This forces sediment to settle away from the open plug and prevents the plug from sticking open.

For vertical pipelines in which over-head drain-back can exist, the valve should be installed with the seat at the top. This prevents drain-back solids from packing into the valve body.

The DeZurik 3-way and 4-way valve

DeZuriks flow diversion valves (Figure 2) typically have three or four ports and are also available with a variety of plug styles, which are chosen based on the desired flow diversion. The most common plug styles are: single-style, double-style, and transfer-style.

The single and double-style plugs can be arranged into different flow combinations. Resilient-seated plugs are used for tight shutoff, and in high-temperature and throttling applications, the plugs are all metal. The transfer-style plug is used in four-way diversion valves designed to shut off the flow of two ports and allow the flow through two other ports.

Flow diversion valves are designed for throttling and diverting clean, dirty, viscous, and corrosive liquids; sludge, abrasive, and fibrous slurries; and clean, dirty, and corrosive gases.

Some multi-ported valves feature lift, turn and reseat, which allows the plug to be moved away from the sealing surface of the body prior to rotating. Because the plug lifts first, plug and seat wear is reduced or eliminated and the valve has longer life. Lift, turn and reseat double hand wheel actuators (Figure 2) provide tight shutoff when used on valves with resilient-faced plugs. A lift, turn and reseat valve with lever actuator is shown in Figure 3. The lever is used to lift the tapered plug away from the seat, providing easy operation. With the plug unseated, no binding or scraping between the plug and seat occurs. At the desired flow position, the plug is re-seated.

Applications for the DeZurik Plug valve

Applications for plug valves are numerous. For example, here are just a few:

• Sewage intake

• Grit removal

• Digester gas

• Effluent

• Pump check control

• Paper

• Sewage transmission

• Process

• Primary and secondary treatment in Mining slurries

• HVAC

• Water

• Power

• Chemical

The Future

DeZurik’s plug valve is a proven durable and reliable performer, while the plug valve has evolved somewhat in the century it’s been around, the basic principle of its operation remains the same; so has its reputation as a proven performer and a long-standing, reliable workhorse. Because of this, the outlook for the DeZurik plug valve is positive, and we can expect to see its continued use in a number of applications decades into the future. For More information on the DeZurik PEC plug valve Contact Flow Technology Services

Tel: +44(0)28 9084 1004

Email: info@flowtechnologyservices.com

Web: www.flowtechnologyservices.co.uk

| Telephone: | 028 9084 1004 |

| Email: | info@flowtechnologyservices.com |

| Website: | www.flowtechnologyservices.com |

| More information on the Flow Technology Services Ltd BVAA Member Directory Page |

Search related valve / actuator articles: Flow Technology Services LtdIssue 41ValvesPlug Valves