Qualification and Innovation driving the subsea valve business

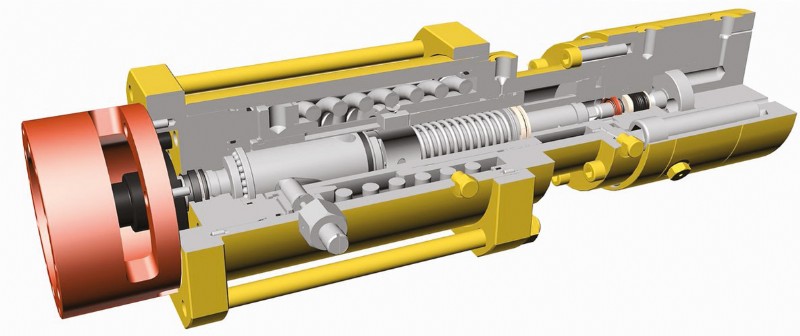

Rotary Gate valve with OPTItork

½” 15K Rotary Gate valve in R&D testing

Over these last few years, despite the difficult market place, LB Bentley (LBB) has continued to invest considerable resource in ensuring that all our product range fully satisfies API 17D 2nd Edition and meets, or exceeds, the appropriate major international standards.

In addition to achieving full qualification of our existing product range and even in this downturn in the Oil & Gas industry, particularly subsea, LBB has continued to drive forward innovation to offer our customers a fuller range of products to satisfy their requirements.

An example of this is our ‘Continuous Development Program’ analysis of the market requirements which is driven by Colin Earle, LBB’s Business Development Manager. We determined that there was a demand for the ⅜˝ Rotary Gate Valve to be available in HH trim at 15,000psi pressure rating, this being a higher level than that currently produced. An important requirement was that the new design had to have the same installation envelope as the other ⅜˝ valves already available and ensure that LBB quality was not compromised in any way.

Whilst the existing 10k (10,000psi pressure rated) product is qualified at 150°C to 10,000ft, a review of the design calculations confirmed that the body and bolting material used for this product were not suitable for the higher stress levels produced by the higher pressures. The solution was to analyse the pressure containing parts using stronger alloys followed by FEA calculations and qualification testing for the new design. A prototype valve has now successfully completed API 17D 2nd Edition qualification including additional endurance cycles to 1,200 cycles and third-party verification, with all modes of operation being available including the actuated version with the new OPTItork™ for remote hydraulic operation.

LBB’s continuous development and qualification plan spans through to the end of 2018, it will continue to be updated and reviewed on an ongoing basis driven by the industry requirements and our customers’ needs.

For further information on our development please contact sales@lb-bentley.com

Tel: +44 (0) 1453 733 060

Email: sales@lb-bentley.com

Web: www.lb-bentley.com

| Telephone: | 01453 733060 |

| Email: | sales@lb-bentley.com |

| Website: | www.lb-bentley.com |

| More information on the LB Bentley Ltd BVAA Member Directory Page |

Search related valve / actuator articles: LB Bentley LtdIssue 42ValvesGate ValvesSafety and StandardsAccreditationR&DRotary Valves