Advanced Valve Solutions, Start-Stop Operation Summary

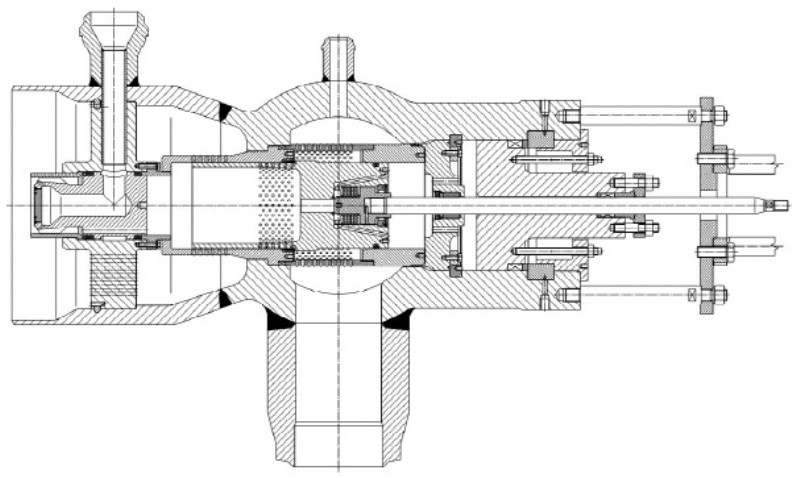

General arrangement drawing of a typical HP Bypass

HP bypass, clamped trim, pressure seal, steam atomizing spray, spherical body

The worldwide introduction of wind, solar power and other renewables create an increasingly flexible demand on gas fired power stations to balance the grid.

To operate in a reliable, quick, modulating and start/stop regime, some improvements are necessary.

To start and to stop a modern CCGT installation takes time and cannot be done instantaneously.

The gas turbine needs to be warmed through as well as the rest of the power plant, the HRSG, (Heat Recovery Steam Generator) downstream of the gas turbine, the interconnecting steam pipework, the steam turbine and all other balance of plant items.

This all must be done as quickly as possible to limit the starting costs and to supply as soon as possible to the grid. In the European markets the driving factor is high fuel costs, reducing the need for full speed no load, however in the USA the driving factor is to reach emission values as soon as possible.

For all CCGT plants the demand for being reliable and the need to be able to start the installation, to supply to the grid, is the single most important driving factor.

The AVS Solution

Advanced Valve Solutions has a bespoke package of dedicated products to solve these problems, based on our specific and extensive experience in these types of operating regimes.

With this package in place, it leads to reduced maintenance costs, to reduce starting time and to upgrade the reliability of you existing installation. With many years of experience and a group of high qualified European manufactures supporting our performance, we deliver a complete solution.

HP Bypass Stations

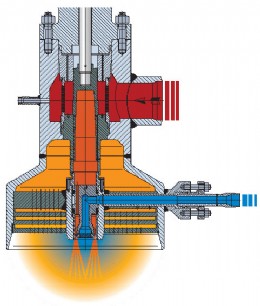

By spraying centrally in an axial direction there is no chance of spraying onto the hot trim parts or onto the downstream piping, which is a typical cause of thermal cracking, there is no backwards spray.

The pilot plug operated balanced trim, is tightly seated during closure, thus can maintain pressure in the boiler following a shut down.

This results in a faster start, by maintaining the pressure in the boiler for longer, ideally suited for allowing a hot start.

By using a steam atomizing unit, the Sauter (D32), diameter of the droplets, is much smaller than droplets formed in a pressure difference driven cooler (for example; spring loaded nozzles in ring type cooler).

The simple reason is that with the Mach 1 velocity of the steam atomizing head, droplets are atomized with a Weber number many factors higher than that of a pressure difference driven cooler, meaning faster and more efficient atomisation, and a finer, more controllable cooling range.

All water is evaporated and no additional water has to be discharged through the drip legs. This water is normally causing thermal problems in the downstream piping.

Tel: 01270 586 944

Email: info@advancedvalvesolutions.co.uk

Web: www.advancedvalvesolutions.co.uk

Published: 29th April 2019

Rachel Wormald, Managing Director at YPS Valves Ltd and Elizabeth Waterman, ...

Are you looking for industry-leading, brand independent valve and actuator ...

As can be seen from the photograph, clearly the resident birds at Bartlett ...

Howco Group has unveiled its latest £1million investment, with the ...

In 2024, Allvalves is poised for an exciting year of growth and expansion, ...

GMM Pfaudler Engineered Plastics & Gaskets are delighted to bring the ...

In the ever-evolving valve industry, GMM Pfaudler stands out for its ...

SAMSON Controls Ltd – part of the SAMSON group - a renowned leader in ...