Anti-Cavitation Valve Trim Helps Improve Plant Availability and Safety

The Fisher Cavitrol Hex trim option provides improved performance in severe service applications while maintaining valve efficiency, resulting in increased safety

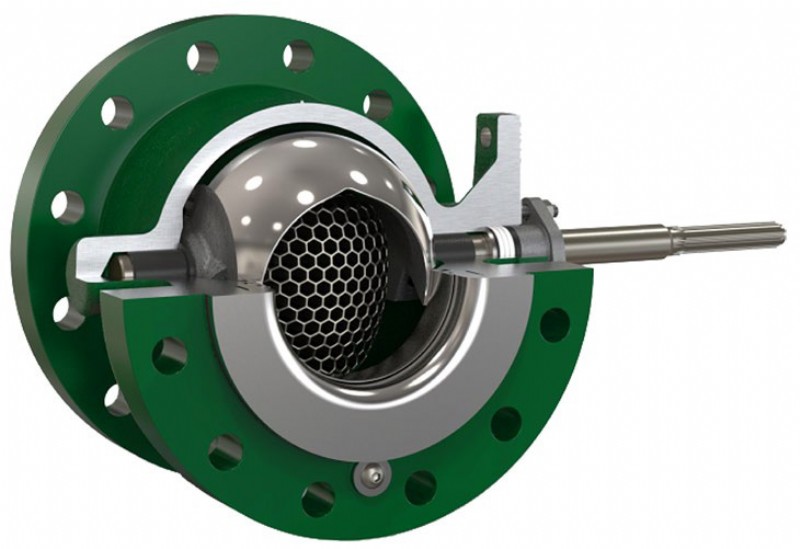

Emerson’s Fisher Vee-Ball™ Rotary Control Valves are now available with Cavitrol™ Hex Anti-Cavitation Trim to reduce or eliminate vibration caused by cavitation. The Cavitrol Hex trim option provides improved performance in severe service applications while maintaining valve efficiency, resulting in increased safety.

Cavitation is the formation and collapse of vapour bubbles (cavities) in liquid flow streams caused by changes in pressure and velocity. There are three primary negative side-effects of uncontrolled cavitation in control valves: excessive vibration, equipment damage and deterioration of flow control.

Vibration can damage equipment and shorten operating life. When equipment deteriorates, flow can’t be controlled properly, negatively impacting plant availability, efficiency and output. Left unchecked, excessive vibration can create unsafe working conditions. The Cavitrol Hex Anti-Cavitation Trim substantially decreases vibration and reduces or eliminates cavitation to improve plant safety.

Cavitrol Hex trim is available on Fisher V150, V200 and V300 rotary control valves. It can be easily retrofitted into previously installed Vee-Ball valves after minimal modifications to the valve body. The trim option is available on Vee-Ball valves in sizes NPS 4 through to 12, providing high capacity for gas, steam and liquids. To meet specific application requirements, a variety of metal and soft ball seal materials are available. Cavitrol Hex trim will not affect valve shut-off or valve temperature limits and does not influence the primary ball/seal interface.

Tel: 0870 240 1978

Email: uksales@emerson.com

Web: www.emerson.com

| Telephone: | 0870 240 1978 |

| Email: | uksales@emerson.com |

| Website: | https://www.emerson.com/en-gb/automation/home |

| More information on the Emerson Process Management Ltd BVAA Member Directory Page |

Search related valve / actuator articles: Emerson Process Management LtdIssue 48Related ProductsFluid ControlFRLsSealsCastingsSafety InterlocksSpringsSurface CoatingsCylindersSteam TrapsFlow MetersCoupling SystemsMaterialsWeld Overlay CladdingPressure RegulatorsInsulationPipingDrive SystemsVolume BoostersSensorsFittingsPosition MonitorsFilter RegulatorsManifoldsGasketsKey ManagementValve CoversSwitch BoxesForgersFastenersBoltingGaugesAlloysMounting Kits