AVS - Drain Valve applications

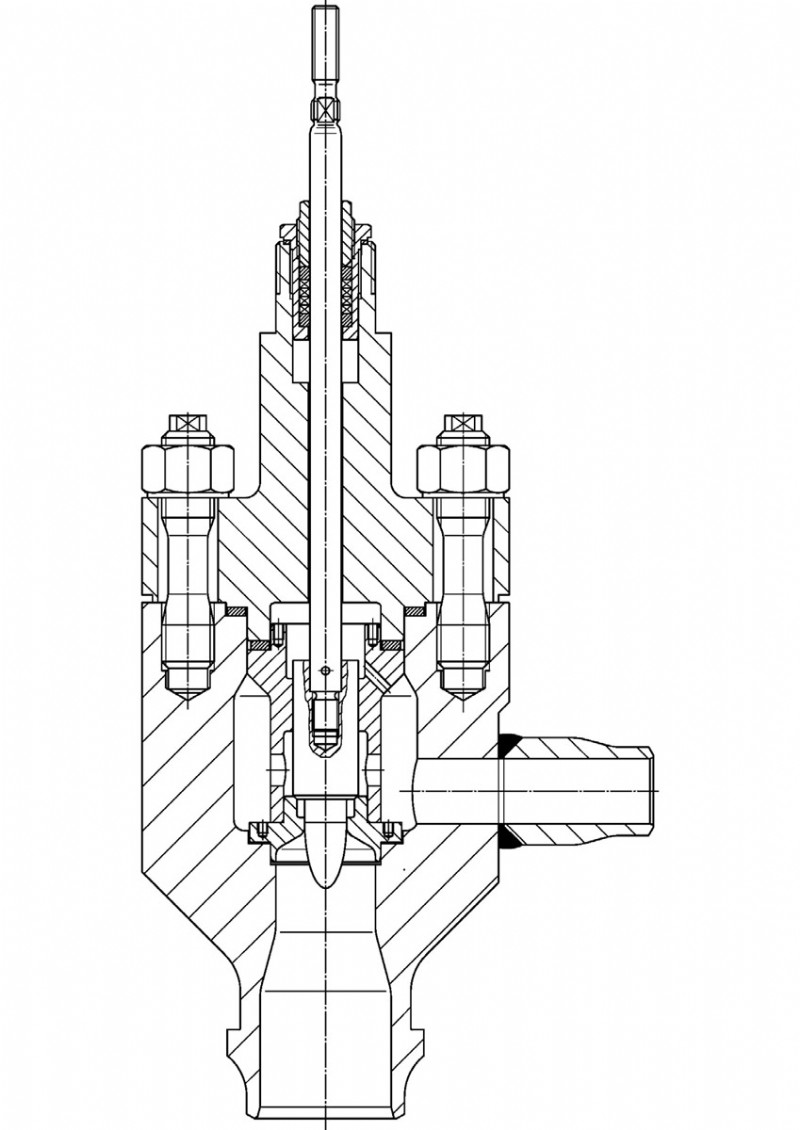

Typical drain valve, clamped trim, separated control and sealing edge, extended outlet size, forged body

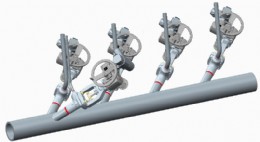

This is the ideal drain valve arrangement, angle type valves, installed at a 45 degree angle into a common line.

To start and to stop a modern CCGT installation takes time and cannot be done instantaneously. The gas turbine needs to be warmed through as well as the rest of the power plant, the HRSG, (Heat Recovery Steam Generator) downstream of the gas turbine, the interconnecting steam pipework, the steam turbine and all other balance of plant items.

This all must be done as quickly as possible to limit the starting costs and to supply as soon as possible to the grid.

In the European markets the driving factor is high fuel costs, reducing the need for full speed no load, however in the USA the driving factor is to reach emission values as soon as possible.

For all CCGT plants the demand for being reliable and the need to be able to start the installation, to supply to the grid, is the single most important driving factor.

The AVS Solution

Advanced Valve Solutions has a bespoke package of dedicated products to solve these problems, based on our specific and extensive experience in these types of operating regimes.

With this package in place, it leads to reduced maintenance costs, to reduce starting time and to upgrade the reliability of your existing installation. With many years of experience and a group of high qualified European manufacturers supporting our performance, we deliver a complete solution.

Drain Valves

A huge concern is the condition of the different types of drain valves on site.

The continuous, the dis-continuous blow down and the super heater drain valves must be monitored carefully.

In a start-stop regime these valves are in operation daily, dealing with the most aggressive process conditions seen on site with high pressure and temperature water/steam and flashing conditions.

We prefer an angle type valve with an increased outlet diameter, fitted with a quick changeable trim and a separate seat and control edge. This allows quick maintenance and extended service life.

Sometimes modifications on the pipe work arrangements are beneficial. The preferred location is always close to the flash-drain tank.

An additional throttling plate can be used to control the back pressure between the valve and the drain vessel in case the valve is located further away.

Tel: 01270 586 944

Email: info@advancedvalvesolutions.co.uk

Web: www.advancedvalvesolutions.co.uk

Published: 9th August 2019

Rachel Wormald, Managing Director at YPS Valves Ltd and Elizabeth Waterman, ...

Are you looking for industry-leading, brand independent valve and actuator ...

As can be seen from the photograph, clearly the resident birds at Bartlett ...

Howco Group has unveiled its latest £1million investment, with the ...

In 2024, Allvalves is poised for an exciting year of growth and expansion, ...

GMM Pfaudler Engineered Plastics & Gaskets are delighted to bring the ...

In the ever-evolving valve industry, GMM Pfaudler stands out for its ...

SAMSON Controls Ltd – part of the SAMSON group - a renowned leader in ...