Optimising control of Butterfly Valves

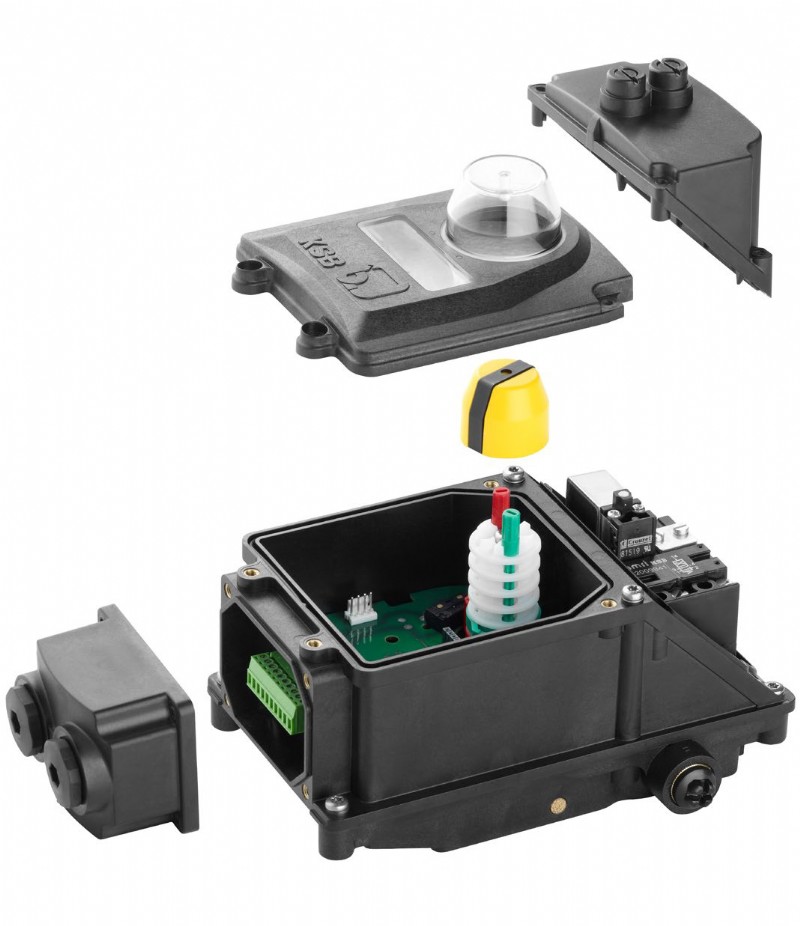

Fig.1: The Amtronic is designed specifically for ON/OFF valve control

Fig.2: The Amtronic can be mounted either to quarter-turn actuators with VDI/VDE 3845 interface or linear actuators with NAMUR interface

These requirements can best be offered through automation using intelligent devices including smart positioners and control units for open/close operations and for collecting data.

Actuated butterfly valves provide the ability to control the flow of liquids in pipelines without manual intervention. This is highly desirable where there are many valves and where valves are in more remote locations.

Using intelligent control units which interface with the actuator offer operators various levels of control suited to the application.

KSB’s automation product range for butterfly valves is based around its Amtronic unit, this being an ON/OFF controller for pneumatic actuators and is comprised of a pneumatic valve and mechanical or proximity switches.

Unlike mechanical switches, proximity switches do not have any moving parts. However, the Amtronic offer the choice so that users can customise units to their specific requirement.

The Amtronic (Fig.1) is designed specifically for ON/OFF valve control and provides two functions, these being ON/OFF control and valve position detection.

The Amtronic can be mounted either to quarter-turn actuators with VDI/VDE 3845 interface or linear actuators with NAMUR interface (Fig.2). Constructed in accordance with IP67 standard, its operating temperature ranges from -20⁰C to +80⁰C and it has a pressure range of 3 to 8 bar.

For double acting pneumatic actuators it can be equipped with three kinds of function, these being 4/2 monostable, 4/2 bistable and 4/3 centre closed. For single acting actuators Amtronic comes with two kinds of function, these being 4/2 monostable and 4/3 centre closed.

The Amtronic is essentially a compact box comprising three separate compartments, these being for pneumatic distribution, position detection and control using mechanical limit switches or proximity switches, and electrical connection.

The design of three compartments means that if there is a need to access a specific function, each compartment can be opened without affecting any of the other compartments.

This has been identified by users as being of significant benefit as it reduces downtime.

Two holes are drilled into the top of the actuator for direct connection to the air supply.

This interface facility gives exactly the same air distribution as a mechanically actuated unit and provides the benefit of no external moving parts and any external piping connections to the actuator.

The Amtronic box can be supplied with a different type of mounting plate for external connection to the compressed air supply for other makes of actuator.

The pneumatic valve and the switches/sensors are installed in the same box, so only one multi-core electrical cable is required for control and position detection.

Should users wish to make a change to access the electronic card and electrical connections, then the terminal block on the rear of the unit can be easily removed so the cable can be connected directly and unplugged if necessary.

In order to eliminate the problem of poor quality compressed air, in-line filtration comes as standard so it does not require quality class 2 or 3 air supply according to ISO 8573-1.

It also means that compressed air is used more economically.

Manual override of the pilot valve and flow reducer to control the air flow and speed of the closing valve is actuated and locked using a screw-driver.

This allows manual control of the valve independently of any external automatic control and the valve can be controlled locally regardless of the remote control signal.

The flow reducers adjust the actuation time and there is no need to add external reducers, nor is it necessary to open the box to access the flow reducers.

Tel: 01509 231 872

Email: sales@ksb.com

Web: www.ksb.com

Published: 8th November 2019

Rachel Wormald, Managing Director at YPS Valves Ltd and Elizabeth Waterman, ...

Are you looking for industry-leading, brand independent valve and actuator ...

As can be seen from the photograph, clearly the resident birds at Bartlett ...

Howco Group has unveiled its latest £1million investment, with the ...

In 2024, Allvalves is poised for an exciting year of growth and expansion, ...

GMM Pfaudler Engineered Plastics & Gaskets are delighted to bring the ...

In the ever-evolving valve industry, GMM Pfaudler stands out for its ...

SAMSON Controls Ltd – part of the SAMSON group - a renowned leader in ...