Parker: High Performance Flange System

Gaining New Certification for Marine Applications

Parker Hannifin, the global leader in motion and control technologies, has announced that its mechanical flange system for machines and plants (with working pressures of up to 420 bar) - “HPF - Parker High Performance Flange System” - has gained DNV GL approval for marine applications. The DGUV approval certifies the use of Parker’s HPF in hydraulic systems for injection moulding machinery as well as in hydraulic and mechanical presses.

This range of products meets the growing requirements of construction, especially for the navy, press manufacturing, injection moulding and mobile work equipment industries. At the same time, the High Performance Flange system significantly contributes to a reduction in assembly time and costs, because it dispenses with the need for error-prone and time-consuming welding processes. The Parker HPF system also has outstanding high pressure and vibration resistance.

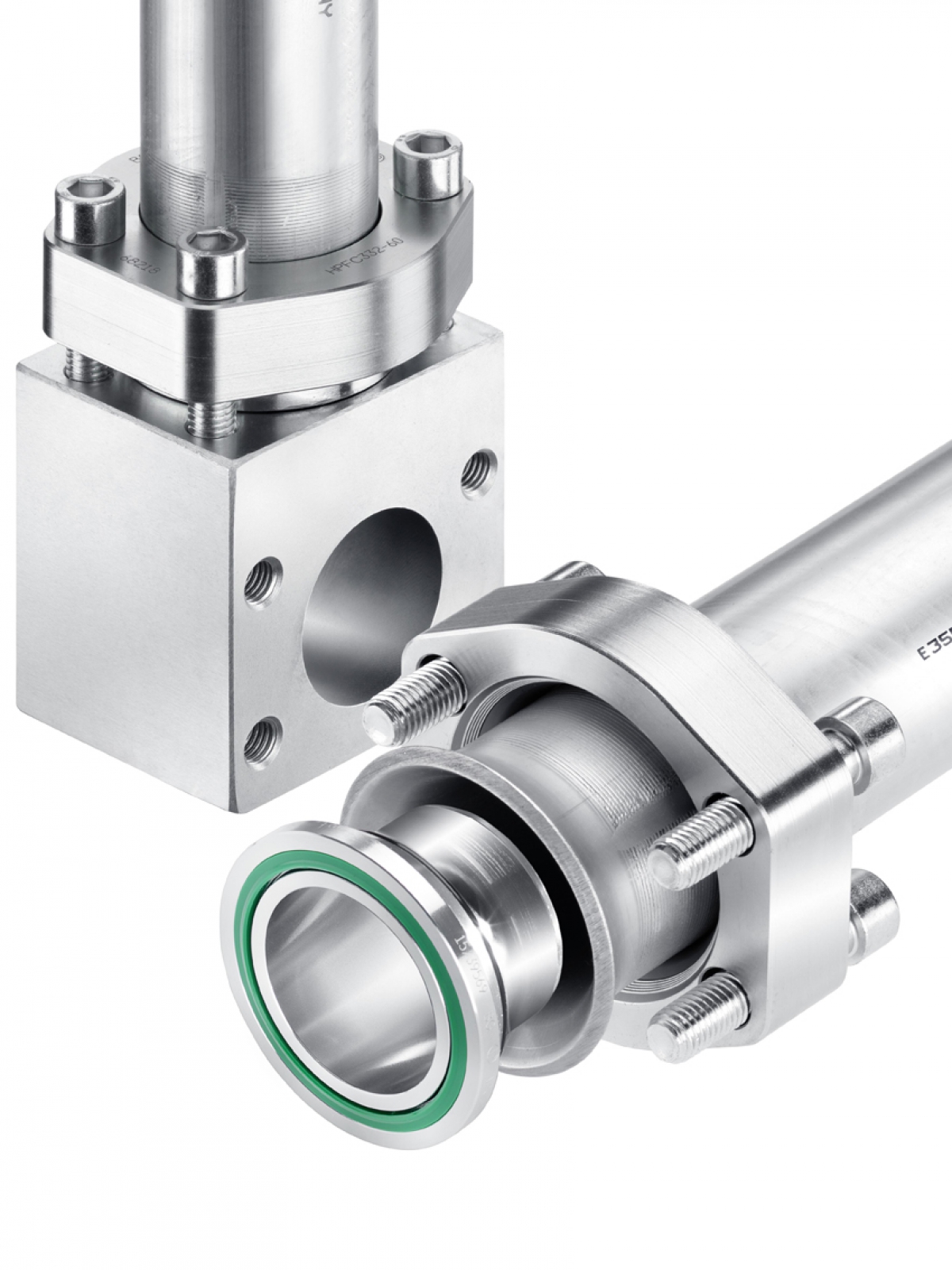

Parker’s High Performance Flange system (HPF) is a form-fit connector system. It complements the proven product range in the field of pipe connector technology with EO2 FORM and F37 for outer pipe diameters from 25 mm. In industrial applications, it provides the ideal replacement for welded pipe connections that are subjected to the highest loads. The HPF system consists of a hardened flange with lock ring contour, an HPF insert (with O ring recess or as a flat-sealing version), and seals on both port and pipe ends to ensure a gas-tight connection.

The system is suitable for use on steel pipes with outer diameters of up to 150 mm. The associated steel components are supplied with environmentally friendly, and extremely corrosion-resistant Cr (VI)-free surface.

Flange sizes range from ¾" to 5" and are available in accordance with ISO 6162-1, ISO 6162-2 or ISO 6164 standards. Pipe flaring is effected in a tulip shape and has no sharp edges. Uniform loading of the surfaces in the whole flange area is achieved with this technology, resulting in very high break resistance.

The forming process is carried out utilising Parflare machinery specially developed for these products and providing hydraulic axial compression. Even large-format tubes can be simply, and above all quickly, handled, thanks to the integrated pipe stop, exemplary ergonomic design, and the high operating convenience of these machines. Apart from its speed of process, HPF technology saves pipe testing and cleaning, processes that are time-consuming and costly compared to conventional welding.

| Tel No: | 01271 313131 |

| Email: | ipd@parker.com |

| Website: | www.ipde-innovations.com |

| Telephone: | 01271 313131 |

| Email: | psc.uk.webform@support.parker.com |

| Website: | www.parker.com/ipd |

| More information on the Parker Hannifin Manufacturing Ltd BVAA Member Directory Page |

Search related valve / actuator articles: Parker Hannifin Manufacturing LtdIssue 64Coupling Systems