Freudenberg’s Simmerring® - Innovative, Functional and Long Lasting

Freudenberg Sealing Technologies has developed a broad portfolio of Simmerring® radial shaft seals to meet the diverse challenges of the food, beverage, pharmaceutical and chemical industries. This includes various product families in different materials that meet the industry specific legal requirements. The original Simmerring® serves as a flexible and highly durable solution for sealing drive shafts. There are special designs made of elastomer materials for use in the process industry, such as 75 Fluoroprene® XP 45, 70 EPDM 291 or 70 NBR 335.

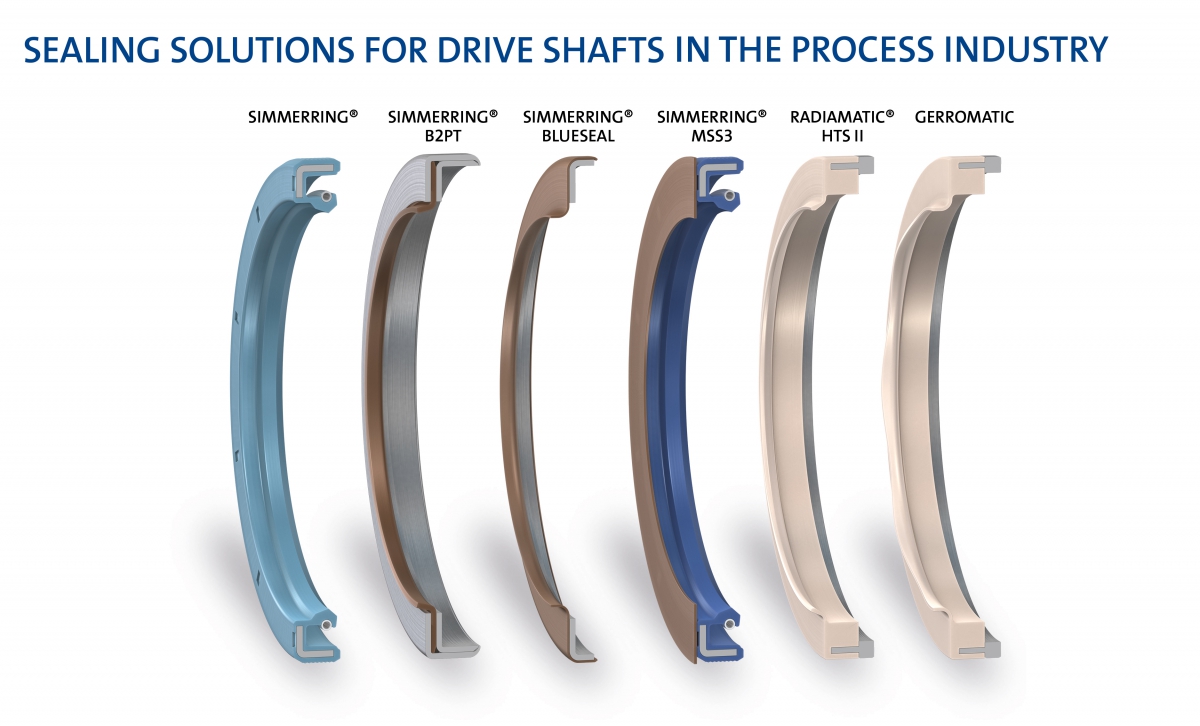

These have been specially developed for contact with foods and pharmaceuticals and are also certified in accordance with industry- and country-specific standards. The Simmerring® product family consists of different designs for the process industry: BAUM as a friction-optimized standard design with a rubberized outer sleeve, BAUMSL with a protective lip for heavily contaminated environments, and BAC as a partially or fully encapsulated radial shaft seal for increased hygiene requirements.

The Simmerring® offers many advantages, such as high resistance to media, good adaptability to customer-specific requirements, and the availability of numerous tools in standard dimensions. Based on the design of the proven Simmerring® , the Simmerring® MSS3 is available both with and without a dust lip. The combination of non-food & beverage standard catalog items with food-grade PTFE lip provides protection against aggressive media and is suited for direct contact with foods and pharmaceuticals. The advantages include quick availability, adaptability to customer-specific application conditions and the availability of numerous tools for standard dimensions.

A distinction is made between the MSS3 as a modified standard BA design with bonded special fleece or a PTFE disc as a protective lip against the finest dirt accumulation and the MSS3 Hygienic Design with an integrated PTFE disc that covers the Simmerring® hygienically and free of dead space. The Simmerring® B2PT was developed for higher pressures, extreme chemical and thermal loads, dry running or deficient lubrication.

The metal housing is made of stainless steel 1.4571 and the sealing lip of a high-performance PTFE material, such as Quantum® PTFE F18245 or Quantum® PTFE F53722. The Simmerring® B2PT enables stick-slip-free operation and can be adapted to customer-specific requirements. The Seite 2 No disclosure to third parties! following designs are available: B2PT for extreme thermal and chemical loads, B2PT Hygienic for increased hygiene requirements and B2PT Split as a version with an additional dust lip. The Simmerring® BlueSeal is ideal for applications with low lubrication, high speeds, extreme temperatures and aggressive media.

Besides its high thermal and chemical resistance, it also offers a friction-optimized PTFE lip design and, like its related products, can be adapted to customer-specific requirements. The three shapes BlueSeal BA as a standard design, BlueSeal B1 with a metallic adhesive part, BlueSeal B1 Reverse with a metallic outer sleeve and BlueSeal BA Reverse Hygienic Design with a PTFE outer sleeve in “Reverse Lip Design” are available in the materials Quantum® PTFE F18245 and Quantum® PTFE F53722. The wide-ranging portfolio of radial shaft seals from Freudenberg Sealing Technologies includes a number of other food-compliant and hygienic solutions.

These are made of high-performance materials and each has a design tailored to specific applications. These include, for example, the Gerromatic or the Radiamatic® HTS II. The experts at Freudenberg Sealing Technologies constantly monitor current market needs and proactively develop new product designs and sealing materials to best meet them. More information can be found here:

|

Tel No: |

01332 524 400 |

|

Email: |

sales.derby@fst.com |

|

Website: |

|

|

LinkedIn: |

| Telephone: | 01332 524 400 |

| Email: | sales.derby@fst.com |

| Website: | https://on.fst.com |

| More information on the Freudenberg Sealing Technologies Ltd BVAA Member Directory Page |

Search related valve / actuator articles: Freudenberg Sealing Technologies LtdIssue 71Seals