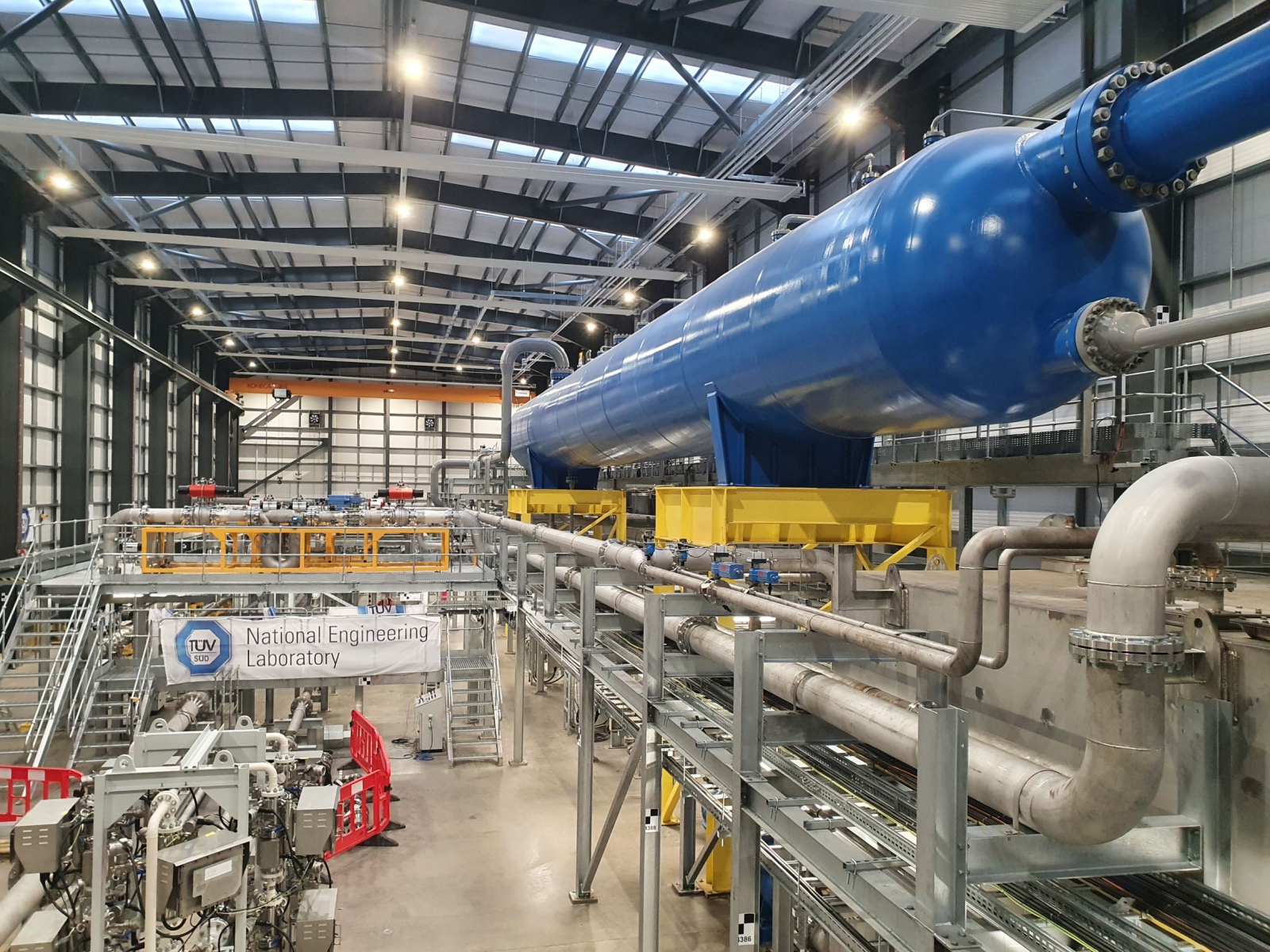

Advanced Multiflow Test Facility with Unique Testing Capability

Advanced Multiflow facility together with 3-phase separator

TÜV SÜD National Engineering Laboratory, a world-leading authority on flow measurement, has been at the forefront of flow measurement technology for over 60 years. It is also the UK’s Designated Institute for Flow Measurement, under contract from the Government’s Department for Business, Energy and Industrial Strategy (BEIS), and part of the UK’s National Measurement System. In addition to flow measurement, the company’s experience of valve testing is unparalleled. The laboratory has a long history of supplying manufacturers and valve end-users with independent and accurate test data.

TÜV SÜD National Engineering Laboratory has created the Advanced Multiflow Test Facility (AMF) at its base in East Kilbride, Glasgow. This revolutionary high-pressure, high-flow rate multiphase facility has a test range beyond anything currently available anywhere in the world. The facility gives the UK valve industry access to full-scale testing.

The AMF facility offers testing up to 140 bar with flows of oil and water up to 83,000 barrels per day with gas flows up to 360 MMscfd. It can operate from 0 to 100 % Gas Volume Fraction and from 0 to 100 % Water in Liquid Ratio. The facility is equipped with state-of-the-art instruments and cutting- edge X-ray tomography technology allowing identification of the flow regime within the pipeline at operating pressure. The use of stabilised fluids, which closely replicate production fluids, allows stability and reproducibility during testing. The facility is built around a high-pressure three-phase separator designed for high separation efficiency. After separation, each of the three phases is circulated and metered separately before mixing and introduction into the test section. Two test lines are available (10-inch and 6-inch with larger sizes up to 16” available on request) and both have a horizontal and vertical section to suit the equipment under test.

In addition to physical flow testing of valves, TÜV SÜD National Engineering Laboratory also has an in-house Computational Fluid Dynamics (CFD) team of experts. They use physical test data to provide a baseline to validate CFD modelling, which can then be utilised as a powerful design optimisation tool for valves and other components.

For more information on how TÜV SÜD National Engineering Laboratory can help with your valve flow testing needs, contact Carl Wordsworth on:

|

Tel No: |

+44 (0)7590 734069 |

|

Email: |

|

|

Website: |

|

|

LinkedIn: |

Search related valve / actuator articles: TUV SUD National Engineering LaboratoryIssue 74TestingMember NewsCompany News