Advanced Valve Solutions - HD2000/200LM Thermal Compensating Globe Valve

Five Benefits

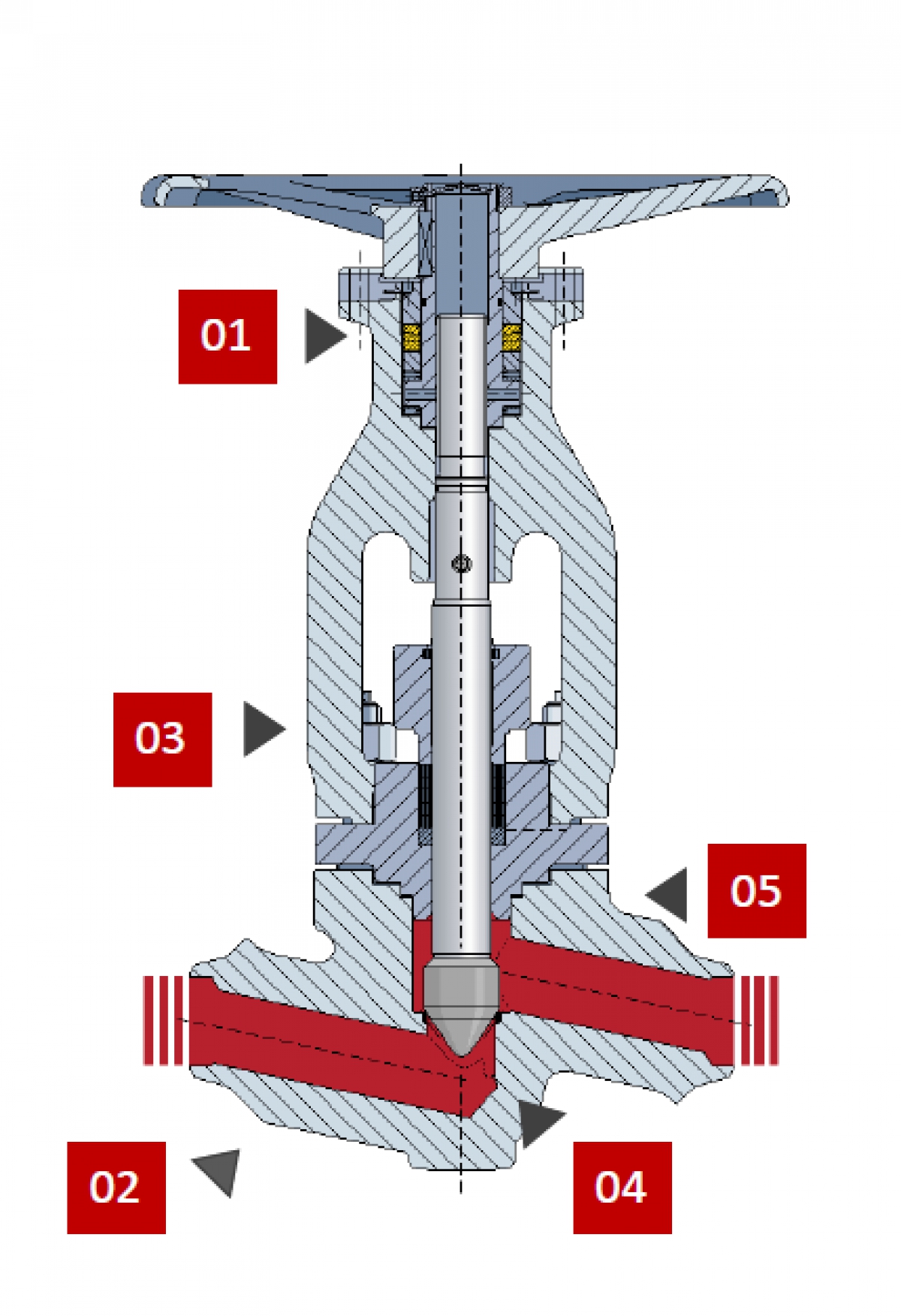

5 Benefits of the HD2000 /200LM Thermal compensating Globe Valve

- "Tight is tight"

Use of cup springs maintain a constant tight seal, between plug and seat during thermal fluctuations. - Forged not cast

Persta forge their valve bodies rather than cast. This eliminates casting defects which can result in cavitation. - 2 become 1

Body and bonnet in two separate pieces, with bolted connection Allowing ease of routine maintenance and access for regrinding of the seat. - Take a seat

The HD2000 benefits from a welded in stellite seat. Therefore, no crevice corrosion or loosening. - Keep it simple

1 piece stem and plug design. One piece design to eliminate failure points between plug and spindle interface.

For more information, contact:

|

Tel No: |

01270 586944 |

|

Email: |

|

|

Website: |

|

|

LinkedIn: |

https://www.linkedin.com/company/advanced-valve-solutions-uk/?isFollowingPage=true |

Published: 26th July 2022

Rachel Wormald, Managing Director at YPS Valves Ltd and Elizabeth Waterman, ...

Are you looking for industry-leading, brand independent valve and actuator ...

As can be seen from the photograph, clearly the resident birds at Bartlett ...

Howco Group has unveiled its latest £1million investment, with the ...

In 2024, Allvalves is poised for an exciting year of growth and expansion, ...

GMM Pfaudler Engineered Plastics & Gaskets are delighted to bring the ...

In the ever-evolving valve industry, GMM Pfaudler stands out for its ...

SAMSON Controls Ltd – part of the SAMSON group - a renowned leader in ...