Emerson Software Optimises Maintenance Based on Valve Condition Data

Saving Manhours and Downtime

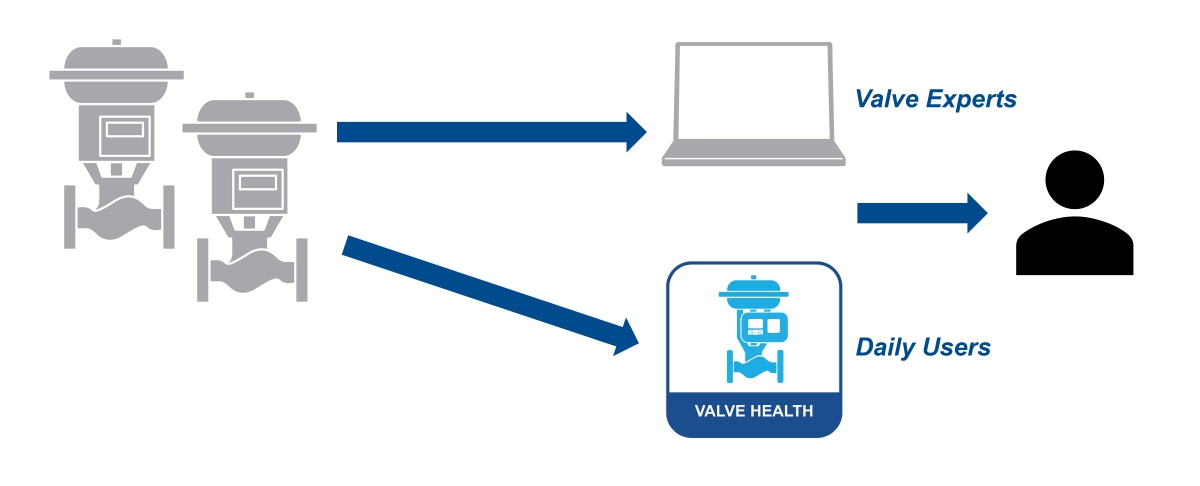

Plantweb Insight™ Valve Health Application utilises advanced diagnostic and analytic algorithms to continuously spot immediate and developing problems across an entire valve network. Alerts are also prioritised to enable daily users to focus on the most pressing problems.

New Valve Health app uses custom data analytics to provide timely plantwide health indicators for improved safety, maintenance and performance.

Emerson has announced the Plantweb Insight™ Valve Health Application, a powerful software tool that combines Fisher control valve expertise with advanced analytic algorithms. The new app makes it possible for users to visualise an entire connected fleet of valves, while prioritising actions based on the health index of each valve. This helps plant personnel optimise valve repair activities, resulting in faster and better maintenance decisions, leading to reduced downtime.

Most process plants and facilities have hundreds of control valves installed and operating in various applications. These valves have multiple parts that must frequently move in concert to regulate flows of process media, with some of these parts coming into constant, direct contact with the media. These operating conditions create wear and tear, requiring maintenance personnel to track the condition of each valve. This is typically done by examining each valve individually, either locally or remotely, a time-consuming endeavour that requires a high level of expertise to ascertain valve health and follow-up action.

The Plantweb Insight Valve Health Application speeds and simplifies this control valve monitoring task by providing a user-friendly interface, with easy-to-understand and intuitive graphics. The app includes Emerson’s Valve Health Index, produced by a proprietary algorithm, which shows plant personnel the level of health for each valve. The Valve Health Index allows users to enter information regarding their plant's processes, including criticality of the valve and financial impact if the valve were to fail, making the index more informative.

The app allows users to prioritise repair and maintenance activities with five different indicators – Repair Urgency Status, Valve Health Index, Financial Impact, Criticality, and NE107 Alert Status – to meet specific needs. The app includes explanations, recommendations, and suggested time to take action. This last indicator is totally new to the market and is one of the app’s exclusive features.

“Plants and facilities harnessing all the functionalities of the Plantweb Insight Valve Health Application will experience reduced analysis time, faster troubleshooting and improved prioritisation of maintenance actions,” said Jaime Alvarado Millan, software product manager for flow controls with Emerson’s final control business. “The result will be fewer man-hours required for repairs and maintenance, increased uptime and fewer unplanned shutdowns. These and other benefits will increase productivity, lower costs and improve profitability.”

To learn more, please visit https://www.emerson.com/en-us/catalog/plantweb-sku-insight-valve-health-application

|

Tel No: |

0870 240 1978 |

|

Email: |

|

|

Website: |

| Telephone: | 0870 240 1978 |

| Email: | uksales@emerson.com |

| Website: | https://www.emerson.com/en-gb/automation/home |

| More information on the Emerson Process Management Ltd BVAA Member Directory Page |

Search related valve / actuator articles: Emerson Process Management LtdIssue 88Control Panels